A kind of sorghum field chemical herbicide seed coating agent and herbicide method

A technology for chemical weeding and sorghum, applied in herbicides and algaecides, botanical equipment and methods, chemicals for biological control, etc. Good weed control effect, reduced incidence and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

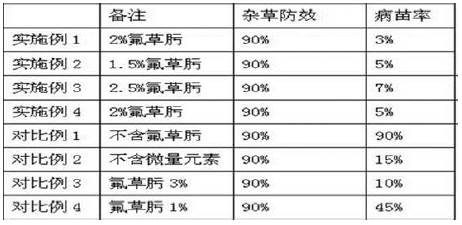

Examples

Embodiment 1

[0038] Embodiment 1 Seed coating preparation scheme

[0039] The raw materials are as follows according to mass percentage: 2% fluroxyxime, 0.2% zinc sulfate, 3% imidacloprid, 5% carbendazim, 1% NNO, 0.3% polyvinyl alcohol, 0.8% xanthan gum, 0.1% ethylene glycol, 0.1% DT-135 defoamer and water were used to prepare 2% fluoxetine seed coating. The specific method is as follows: first use a grinding machine to grind zinc sulfate, imidacloprid, and carbendazim to a fineness of 2-4um, add the dispersant NNO and 96% fluorenzoxime EC to the grinding liquid, stir well, and then Add polyvinyl alcohol, xanthan gum, ethylene glycol, defoamer DT-135 and water, stir thoroughly for 30 minutes to mix all ingredients evenly, and wait for seed coating to be used.

Embodiment 2

[0040] Embodiment 2 Seed coating preparation scheme

[0041] The raw materials are as follows according to the mass percentage: 1.5% fluoroxime, 0.24% zinc sulfate, 2.5% imidacloprid, 4% carbendazim, 1.2% NNO, 0.2% polyvinyl alcohol, 1.0% xanthan gum, 0.12% of ethylene glycol, 0.07% of DT-135 defoamer and water were prepared into 1.5% of fluoxetine seed coating. The specific method is as follows: first use a grinding machine to grind zinc sulfate, imidacloprid, and carbendazim to a fineness of 2-4um, add the dispersant NNO and 96% fluorenzoxime EC to the grinding liquid, stir well, and then Add polyvinyl alcohol, xanthan gum, ethylene glycol, defoamer DT-135 and water, stir thoroughly for 30 minutes to mix all ingredients evenly, and wait for seed coating to be used.

Embodiment 3

[0042] Embodiment 3 kinds of coating agent preparation schemes

[0043] The raw materials are as follows according to mass percentage: 2.5% fluoroxime, 0.16% zinc sulfate, 3.5% imidacloprid, 6% carbendazim, 0.8% NNO, 0.4% polyvinyl alcohol, 0.6% xanthan gum, 0.08% ethylene glycol, 0.13% DT-135 defoamer and water were used to prepare 2.5% fluoxetine seed coating. The specific method is as follows: first use a grinding machine to grind zinc sulfate, imidacloprid, and carbendazim to a fineness of 2-4um, add the dispersant NNO and 96% fluorenzoxime EC to the grinding liquid, stir well, and then Add polyvinyl alcohol, xanthan gum, ethylene glycol, defoamer DT-135 and water, stir thoroughly for 30 minutes to mix all ingredients evenly, and wait for seed coating to be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com