Chelating system for shower gel processing

A shower gel and meshing technology, which is applied in the field of shower gel processing systems, can solve the problems of inability to guarantee the same amount of ingredients, and achieve the effects of high-quality boiled products and high mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

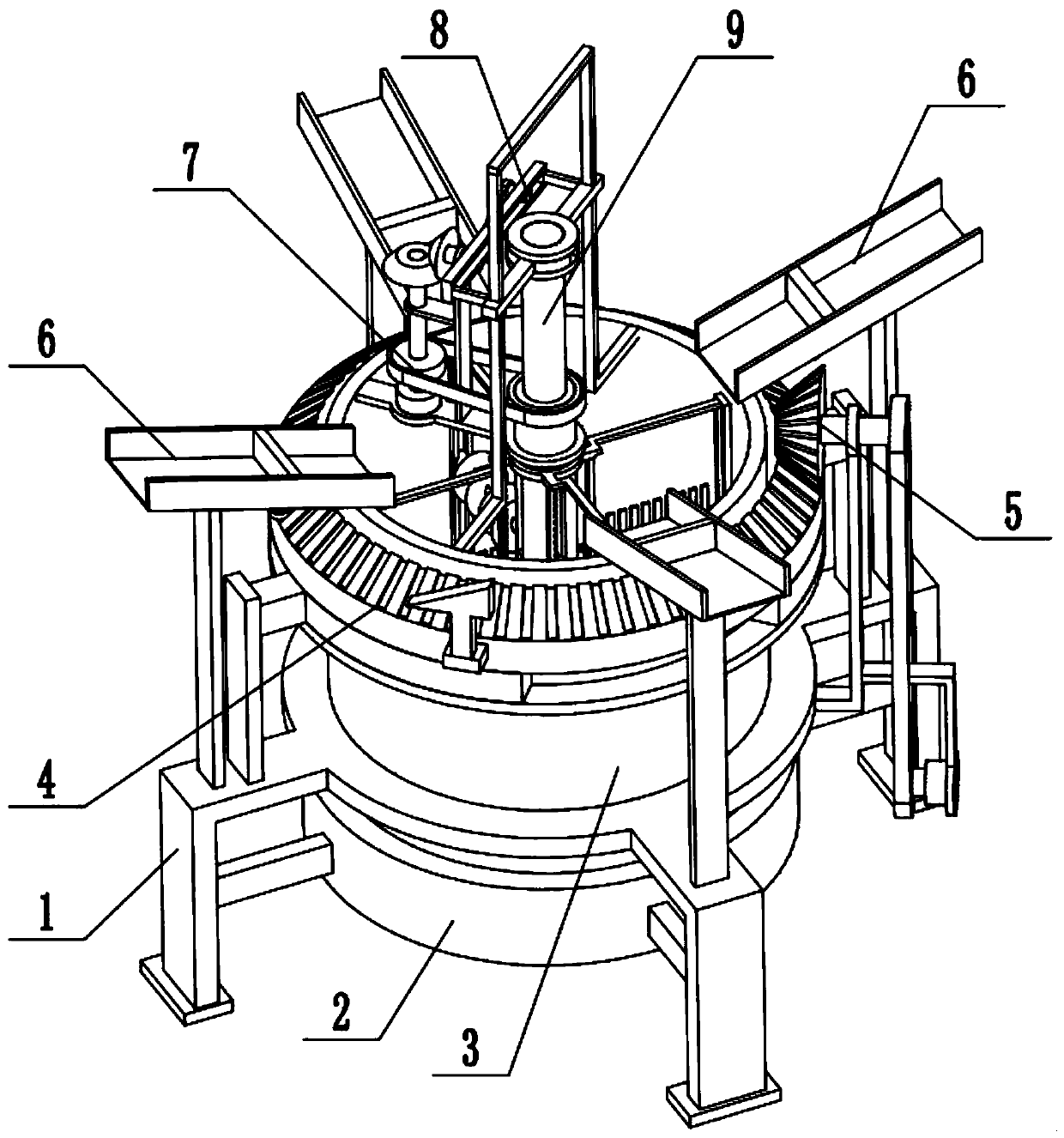

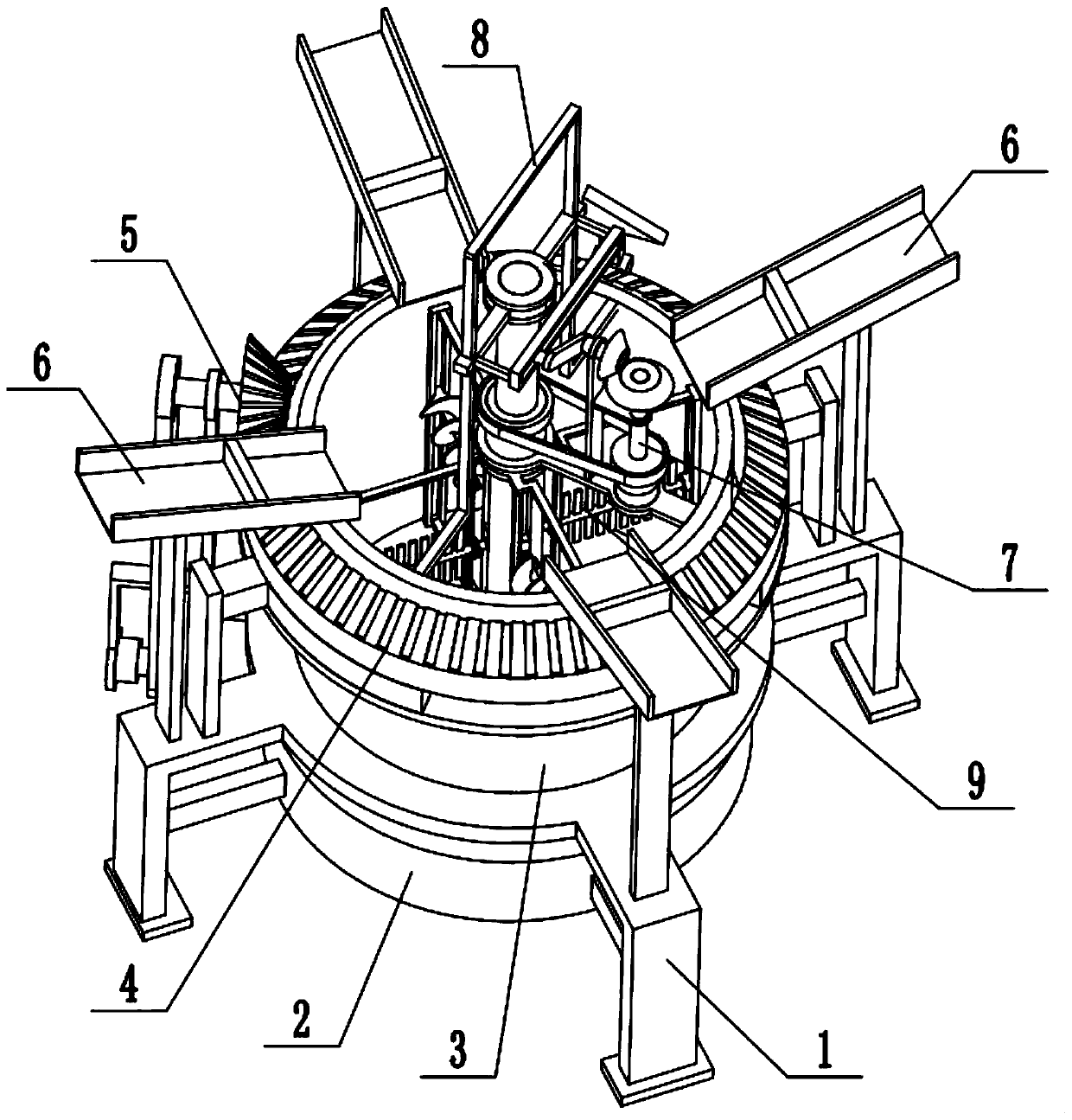

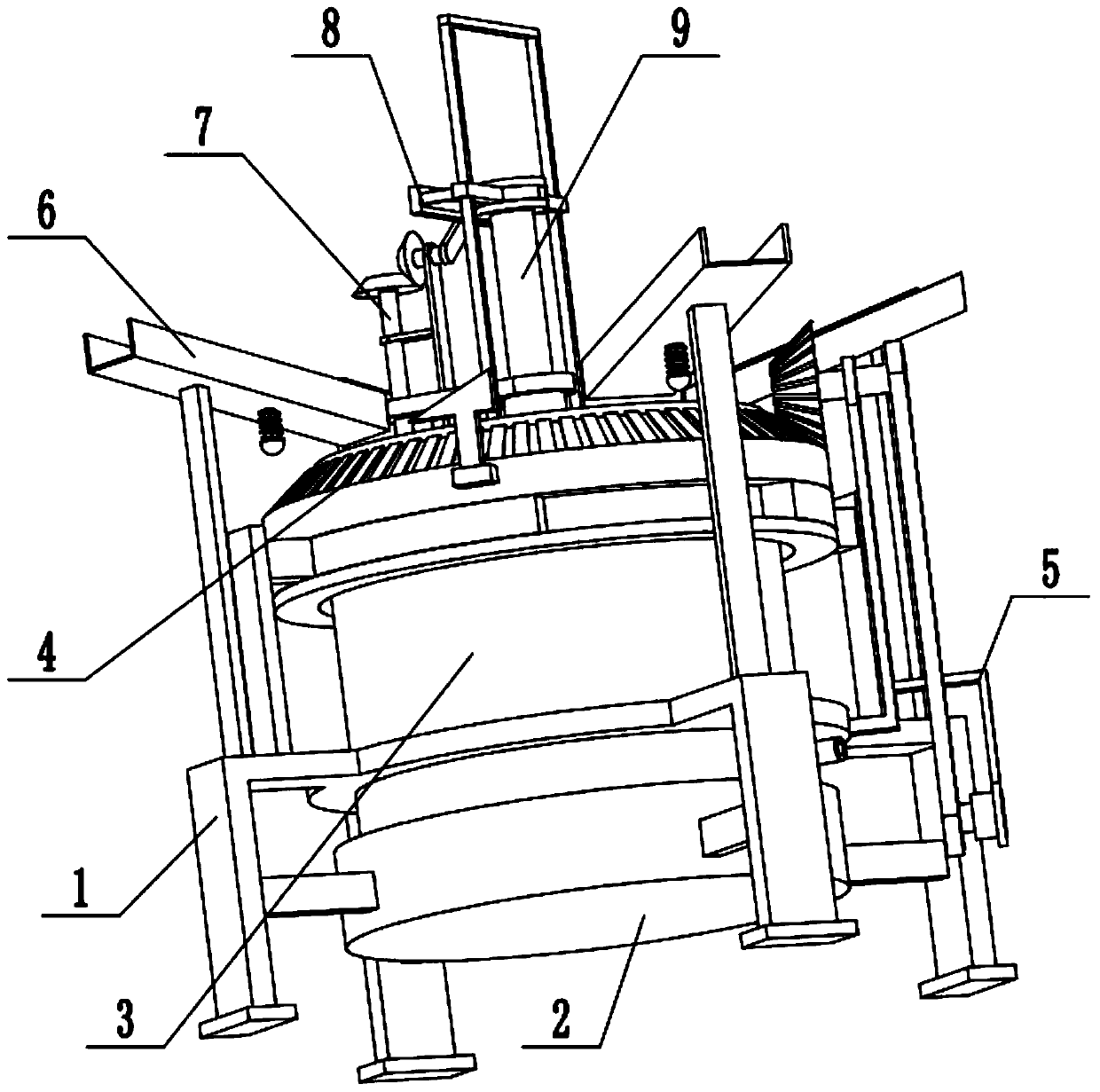

[0031] Combine below Figure 1-12 Describe this embodiment, a boiling system for shower gel processing, including a frame 1, an electric heating device 2, a boiling mixing tank 3, an intermittent feeding control mechanism 4, an intermittent feeding driving mechanism 5, and a material holding device 6 , a power drive device 7, a reciprocating control mechanism 8 and an agitator 9, the electric heating device 2 is fixedly connected to the frame 1, the boiling mixing bucket 3 is fixedly connected to the frame 1, and the boiling mixing bucket 3 is located at the electric The upper end of the heating device 2 and the lower end of the mixing bucket 3 are provided with a drain pipe with a control valve, the intermittent feeding control mechanism 4 is connected to the frame 1 with gap fit, and the boiling mixing bucket 3 is located in the intermittent feeding control mechanism 4, the intermittent feeding drive mechanism 5 is fixedly connected to the frame 1, the intermittent feeding d...

specific Embodiment approach 2

[0033] Combine below Figure 1-12 To illustrate this embodiment, the frame 1 includes a support switch 1-1, a support leg 1-2, a support rod 1-3, a vertical rod 1-4, a shift fork I1-5 and a shift fork frame 1-6; One support leg 1-2 is evenly surrounded and fixedly connected to the support switch 1-1, and the four support legs 1-2 are fixedly connected to a support rod 1-3, and the four support rods 1-3 are uniformly surrounded and fixedly connected to the electric heating On the device 2, the boiling mixing bucket 3 is fixedly connected in the support 1-1, the boiling mixing bucket 3 is located above the electric heating device 2, and the upper ends of the four supporting legs 1-2 are fixedly connected to a vertical rod 1-4 , the four material holding devices 6 are respectively fixedly connected to the four vertical rods 1-4, and the outer sides of the two shift forks I 1-5 are fixedly connected to a shift fork frame 1-6, and the two shift fork frames 1-6 are symmetrically fix...

specific Embodiment approach 3

[0035] Combine below Figure 1-12 To illustrate this embodiment, the intermittent blanking control mechanism 4 includes an annular frame 4-1, an annular groove 4-2, a bevel gear 4-3, a T-shaped frame 4-4, and a right-angled triangle block 4-5; the annular frame The lower end of 4-1 is provided with an annular groove 4-2, and the top surface of the annular frame 4-1 is fixedly connected to the bevel gear 4-3, and the bevel gear 4-3 is meshed with the intermittent feeding drive mechanism 5 for transmission connection, and the two dials The inner side of the fork I 1-5 is connected in the annular groove 4-2 with clearance fit, the T-shaped frame 4-4 is fixedly connected to the upper end of the annular frame 4-1, and the right-angled triangle block 4-5 is fixedly connected to the T-shaped frame 4-4 . When the intermittent blanking control mechanism 4 is in use, the intermittent blanking drive mechanism 5 drives the bevel gear 4-3 to rotate clockwise, the bevel gear 4-3 drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com