A mechanical flotation machine

A flotation machine and mechanical technology, applied in the field of flotation machines, can solve the problems of inability to fix bubbles, small aeration, sedimentation, etc., and achieve good flotation effect, safe and convenient use, and good effect of scraping bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

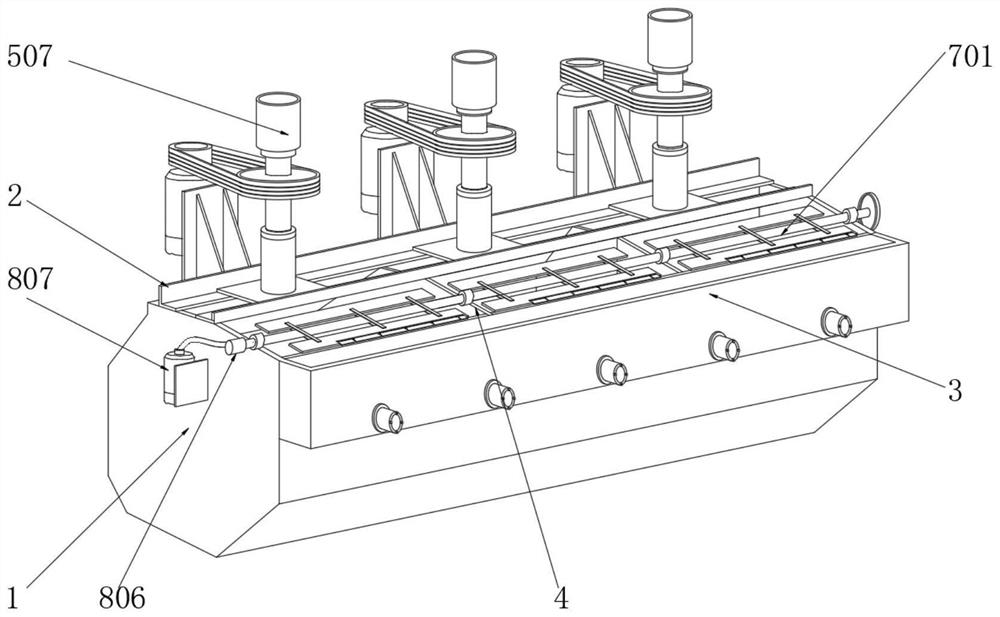

[0039] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, a mechanical flotation machine, comprising a flotation cell 1, a mounting frame 2 is fixedly installed on the top of the flotation cell 1, and a selection tank 3 is fixedly installed on the top of the front of the flotation cell 1 , the inside of the flotation cell 1 is uniformly and fixedly equipped with partitions 4 .

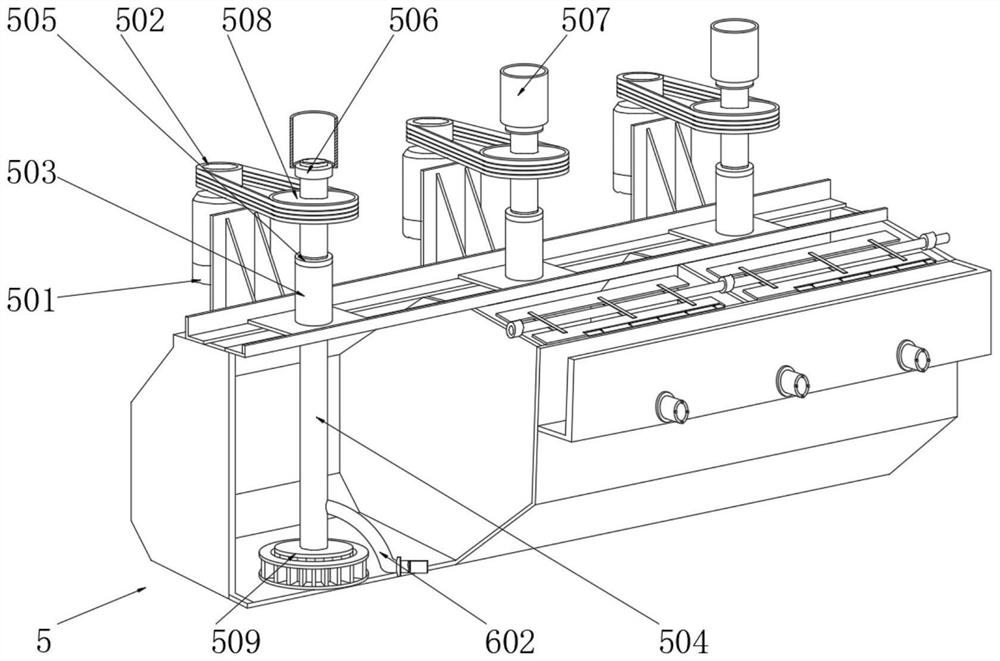

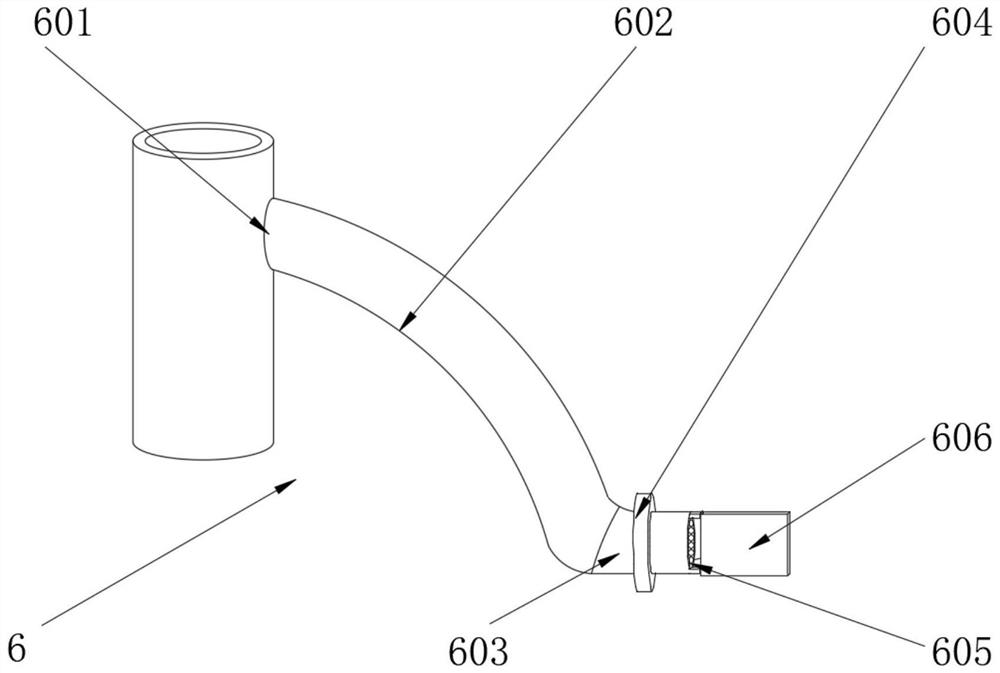

[0040] The drive assembly 5 is installed on the top surface of the installation frame 2, and the drive assembly 5 includes a drive motor 501, a first pulley 502, a positioning pipe 503, a transmission pipe 504, a limit ring 505, a first bearing 506, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com