Stirring head temperature measuring structure for friction stir welding of robot

A technology of friction stir welding and stirring head, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as difficulty in temperature collection, and achieve the effect of verifying the accuracy of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

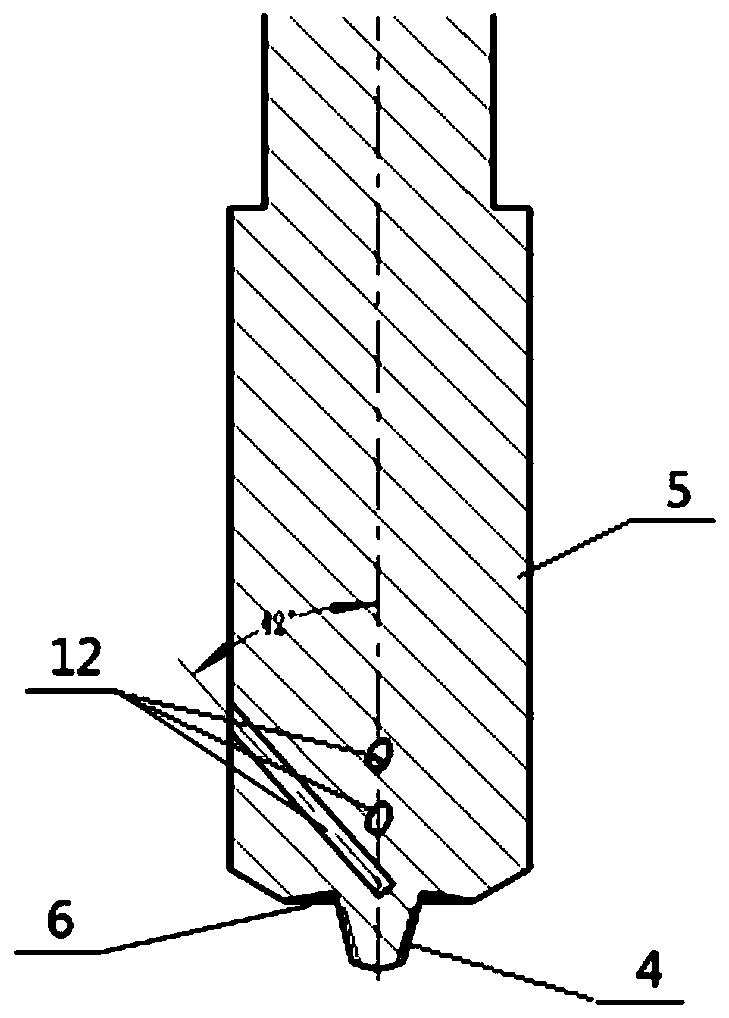

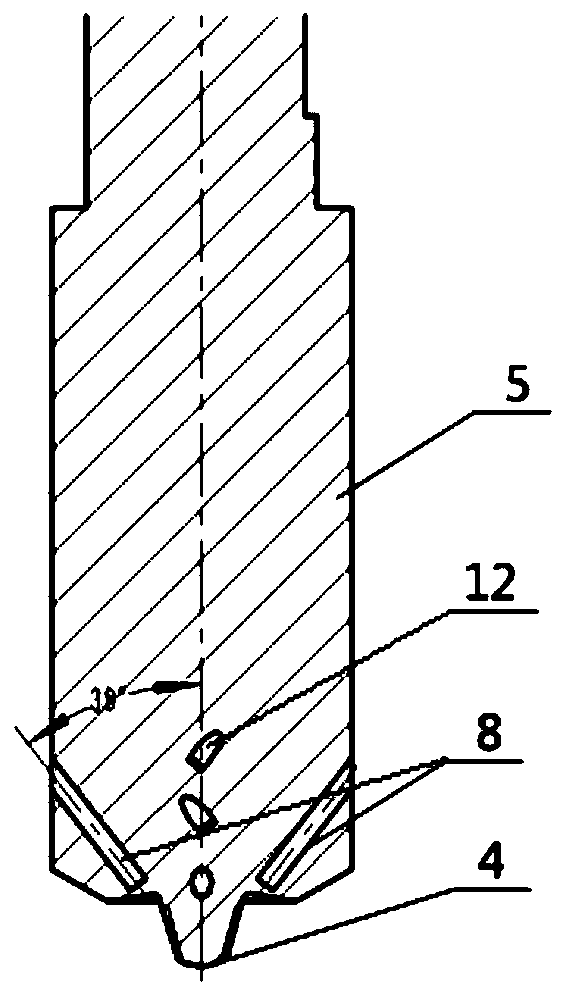

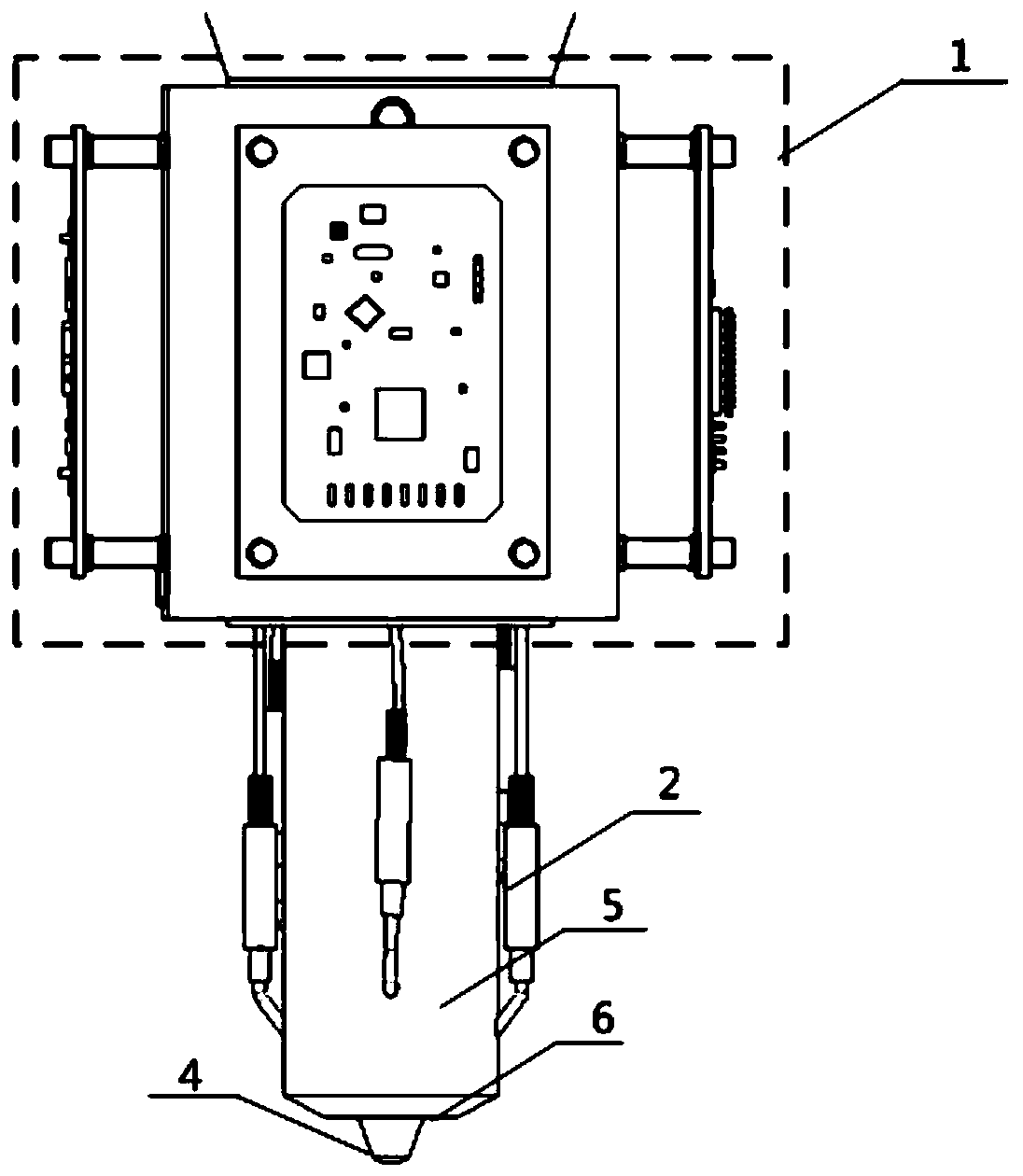

Method used

Image

Examples

Embodiment 1

[0039] The thermocouple can use the wired acquisition method for temperature acquisition. Specifically, the thermocouple acquisition signal is input through the electric slip ring rotor end, the electric slip ring stator end outputs the signal, and the temperature is collected through the LMS data acquisition instrument.

Embodiment 2

[0041] The thermocouple can use the wireless acquisition method for temperature acquisition. Specifically, the signal is collected through the main control module and transmitted to the A / D conversion module for digital-to-analog conversion, and the digital signal is sent through the wireless module. Set up the receiving end of the wireless signal, receive the signal through the serial port, and use the host computer program written by LABVIEW to complete the data collection and real-time display of the temperature.

[0042] Figure 4 It is the temperature acquisition curve figure of acquisition system upper computer in one embodiment of the present invention; Figure 4 As shown, the abscissa represents temperature, and the ordinate represents time. In this embodiment, four thermocouples are used for testing, and the temperature gradient can be clearly seen, and the temperature measured is reasonable. The highest temperature is the thermocouple near the bottom of the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com