Refractory brick layer erosion rate monitoring device and method

A monitoring device and technology of refractory bricks, which are applied in the field of corrosion rate monitoring devices, can solve the problems of lack of effective monitoring of refractory brick status, and achieve comprehensive and accurate monitoring results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

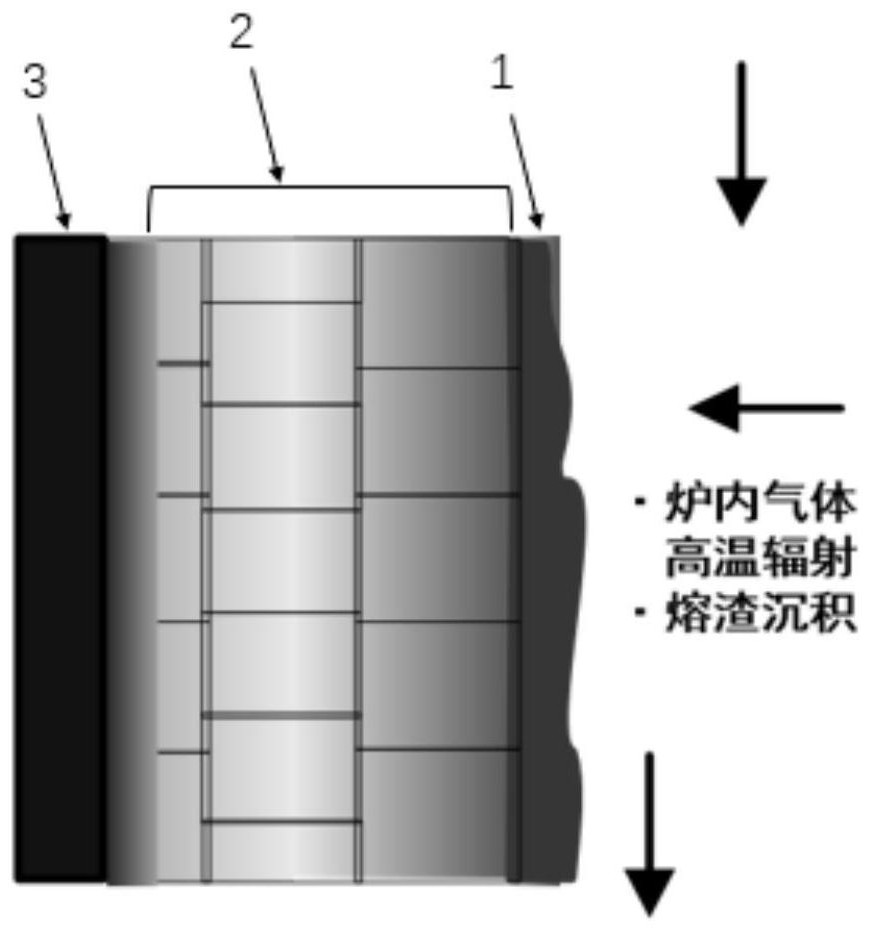

[0073] The furnace body monitored in this example is a gasifier of 1500 tons of coal in a day, such as figure 1 It is shown that the liquid slag layer 1, the refractory brick layer 2, and the metal wall 3, and the refractory brick layer 2, including the refractory brick layer 2, including the inside to the fire brick layer, backing brick layer, and insulating brick layer. The detailed operating parameters of the gasifier furnace are shown in Table 1.

[0074] Table 1

[0075]

[0076]

[0077] The coal quality data in the gasifier furnace is shown in Table 2 below.

[0078] Table 2

[0079]

[0080] The physical properties of the slag in the refractory brick layer of the gasifier and the liquid slag layer are shown in Table 3 below.

[0081] table 3

[0082]

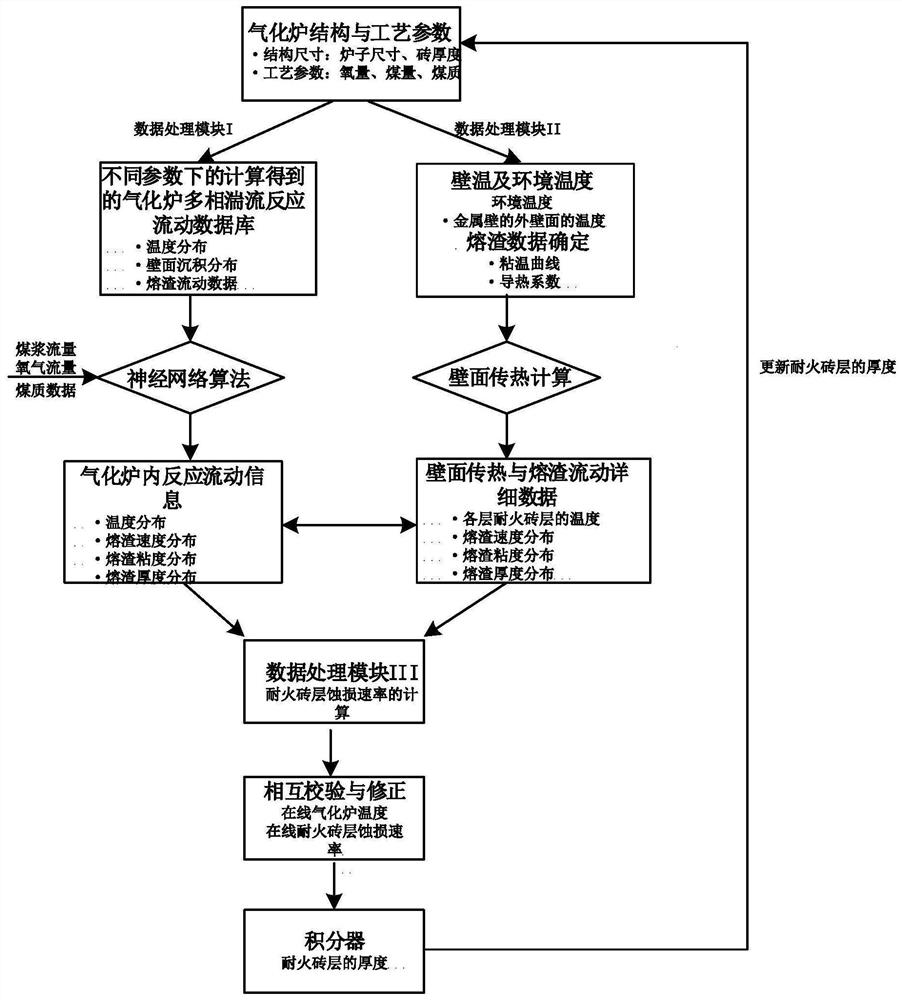

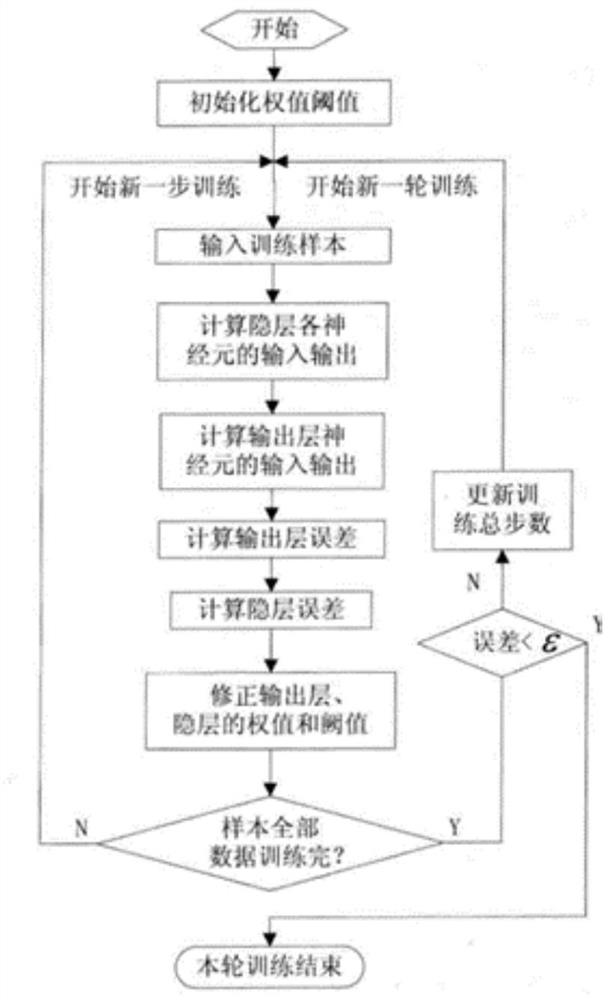

[0083] The monitoring apparatus in this embodiment includes a data acquisition module connected to the gasifier, further comprising a data processing module, a data acquisition module, a data processing module for ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com