Integrated test method for filtration loss and displacement efficiency of horizontal well

A technology of displacement efficiency and testing method, which is applied in earthwork drilling, wellbore/well components, construction, etc., can solve the problems of lowering work efficiency, tediousness, and damage to mud cake on the core surface, so as to improve the convenience of disassembly and improve Work efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

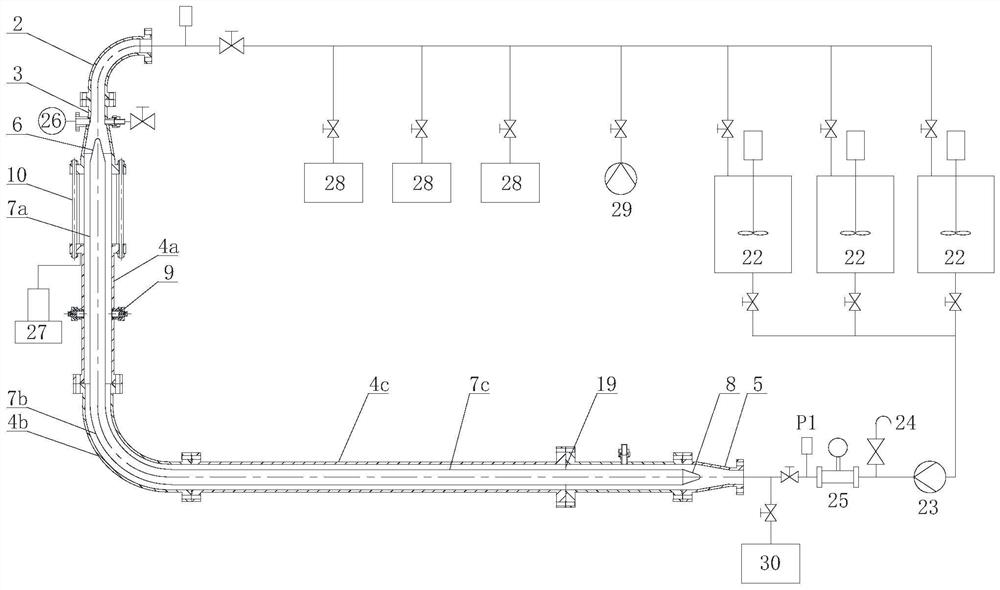

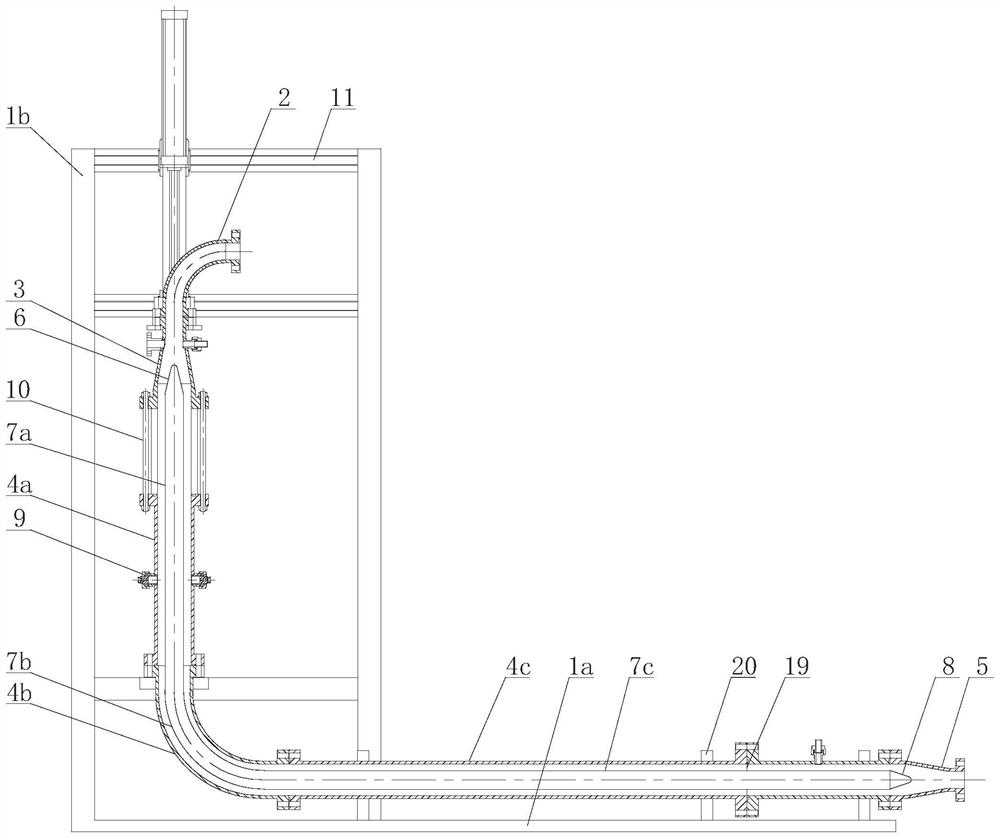

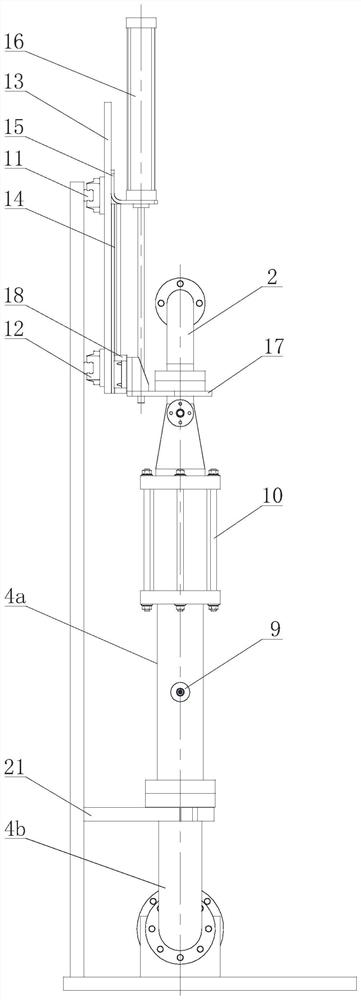

[0031] like figure 1 As shown, the cleaning simulation test device used in the present invention includes a ring rock fluid loss holder, a column rock fluid loss holder and a cleaning simulation test device. The cleaning simulation test device includes a plurality of sample preparation tanks 22, mud pumps 23, Simulate the test cylinder and the test liquid collection tank 28, the outlet of each sample preparation tank 22 is respectively connected with the inlet of the mud pump 23 through the outlet valve of the preparation tank, and the outlet pipeline of the mud pump 23 is sequentially installed with a safety protection device 24 and an online flow meter 25 And the inlet pressure sensor P1, and then connected to the inlet of the lower conical joint of the simulated test cylinder, the simulated test cylinder is L-shaped and fixed on the frame, the upper end of the simulated test cylinder is connected with the upper conical joint, and the side of the upper conical joint An in-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com