Electric automobile battery tray welding clamp

A technology for battery trays and welding fixtures, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of no secondary confirmation of positioning, etc., achieve improved work efficiency, high sensory accuracy, and increased adsorption sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

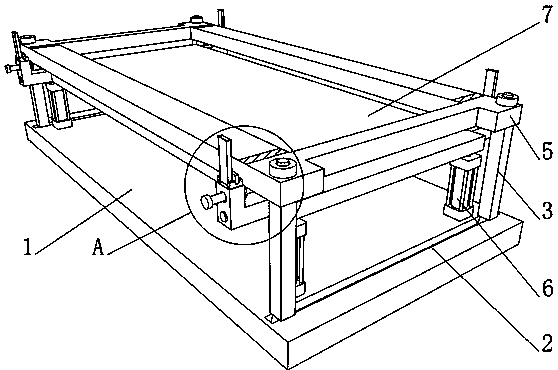

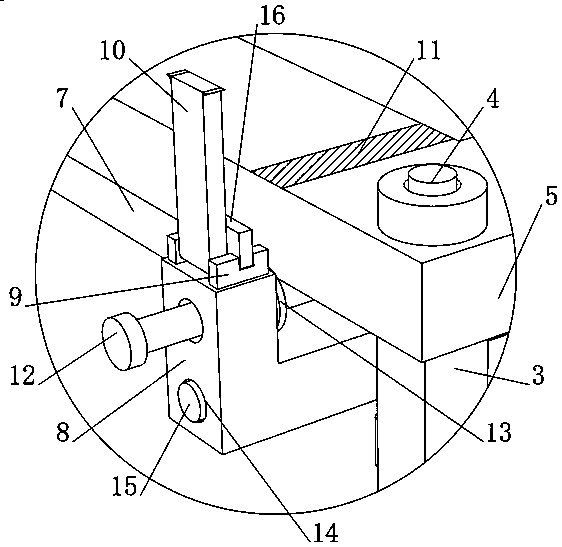

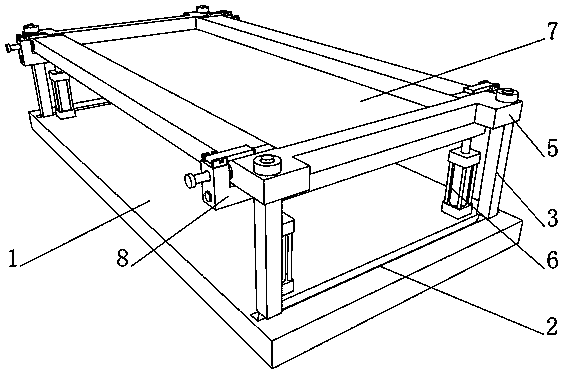

[0031] see Figure 1-3 , an electric vehicle battery tray welding jig, comprising a mounting plate 1, a restraining wire frame 5 and a tray 7, the mounting plate 1, the tray 7 and the restraining wire frame 5 are distributed sequentially from bottom to top, and the upper end of the mounting plate 1 is provided with two mutual Symmetrical chute 2, two sliding rods 3 are slidably connected in the chute 2, the mutual contact between the chute 2 and the sliding rod 3 is set as an inverted trapezoid that matches each other, and the mutual contact between the chute 2 and the sliding rod 3 is set There is a polishing layer, which can reduce the possibility of the sliding bar 3 detaching from the chute 2 during the clamping process by setting it as an inverted trapezoid that matches each other, thereby causing the possibility of accidental damage to the equipment.

[0032] The upper end of the slide bar 3 is fixedly connected with the round rod 4, and the upper end of the restraining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com