Electrolysis method of lead with high bismuth content

A lead electrolysis and electrolyte technology, applied in electrolysis process, electrolysis components, electrodes, etc., can solve the problems of inability to produce high-grade lead, deterioration of production status, unsuitable treatment of crude lead, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Anode chemical quality: Bi≤25%, Pb≤80%, Sb≤6%;

[0019] Electrolyte composition: H 2 SiF 6 :40~80g / L; Pb 2+ :20~80g / L; Bi 2+ :<0.006g / L;

[0020] (2) Electrolyte circulation: 25L / min;

[0021] (3) Electrolysis temperature: 20℃;

[0022] (4) Current density: 60A / m 2 ;

[0023] (5) Electrolysis cycle: 5d;

[0024] (6) Physical specifications of the starting pole piece (effective electrodeposition area): 780mm×670mm×1mm;

[0025] (7) The physical specification of anode: 740mm×600(±20)mm×30mm, the weight of a single piece is 80kg~100kg; the physical specification of cathode: 900mm×670mm×1mm;

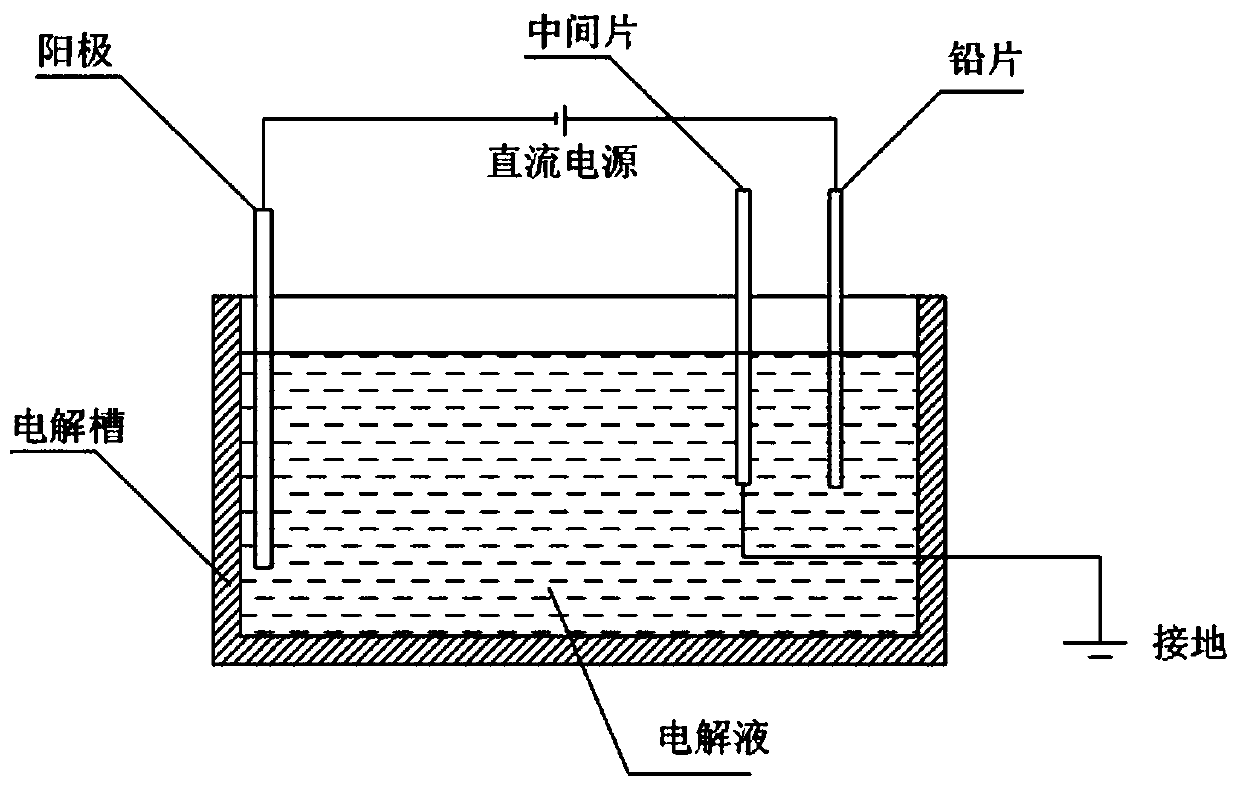

[0026] Further, the cathode is divided into two pieces, one piece is lead, the other piece is an intermediate piece, the lead piece is connected to the negative electrode of the power supply, and the intermediate piece is grounded; the intermediate piece is bismuth.

[0027] Further, the intermediate piece is between the anode and the lead piece, and the distance between the lead piece and the ...

Embodiment 2

[0029] (1) Anode chemical quality: Bi≤25%, Pb≤80%, Sb≤6%;

[0030] Electrolyte composition: H 2 SiF 6 :40~80g / L; Pb 2+ :20~80g / L; Bi 2+ :<0.006g / L;

[0031] (2) Electrolyte circulation: 25L / min~30L / min;

[0032] (3) Electrolysis temperature: 30℃;

[0033] (4) Current density: 80A / m 2 ;

[0034] (5) Electrolysis cycle: 8d;

[0035] (6) Physical specifications of the starting pole piece (effective electrodeposition area): 780mm×670mm×1mm;

[0036] (7) The physical specification of anode: 740mm×600(±20)mm×30mm, the weight of a single piece is 80kg~100kg; the physical specification of cathode: 900mm×670mm×1mm;

[0037] Further, the cathode is divided into two pieces, one piece is lead, the other piece is an intermediate piece, the lead piece is connected to the negative electrode of the power supply, and the intermediate piece is grounded; the intermediate piece is bismuth.

[0038] Further, the intermediate piece is between the anode and the lead piece, and the distance between the lead piece ...

Embodiment 3

[0040] (1) Anode chemical quality: Bi≤25%, Pb≤80%, Sb≤6%;

[0041] Electrolyte composition: H 2 SiF 6 :40~80g / L; Pb 2+ :20~80g / L; Bi 2+ :<0.006g / L;

[0042] (2) Electrolyte circulation: 27L / min;

[0043] (3) Electrolysis temperature: 25℃;

[0044] (4) Current density: 70A / m 2 ;

[0045] (5) Electrolysis cycle: 7d;

[0046] (6) Physical specifications of the starting pole piece (effective electrodeposition area): 780mm×670mm×1mm;

[0047] (7) The physical specification of anode: 740mm×600(±20)mm×30mm, the weight of a single piece is 80kg~100kg; the physical specification of cathode: 900mm×670mm×1mm;

[0048] Further, the cathode is divided into two pieces, one piece is lead, the other piece is an intermediate piece, the lead piece is connected to the negative electrode of the power supply, and the intermediate piece is grounded; the intermediate piece is bismuth.

[0049] Further, the intermediate piece is between the anode and the lead piece, and the distance between the lead piece and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com