A kind of preparation method of environment-friendly type silica gel synthetic leather

A synthetic leather and environment-friendly technology, applied in the field of synthetic leather, can solve the problems of poor flex resistance, abrasion resistance and softness, etc., and achieve the effects of good softness, wide application prospects, and strong compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

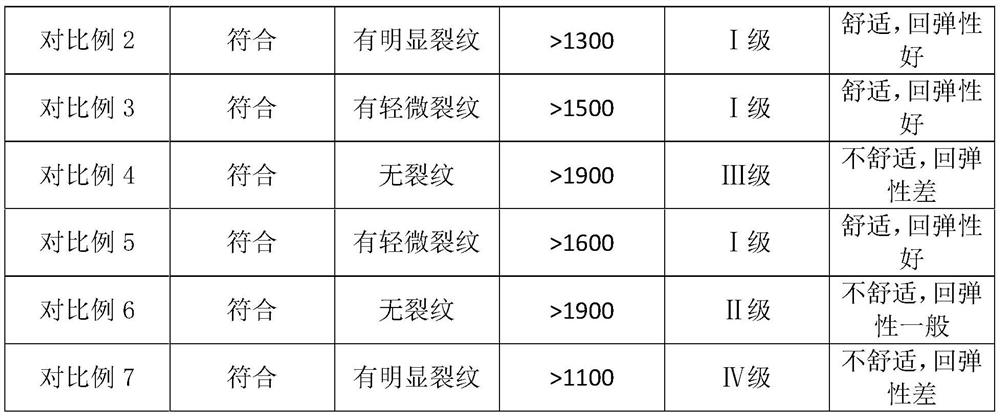

Examples

Embodiment 1

[0024] A kind of preparation method of environment-friendly type silica gel synthetic leather, the step comprises

[0025] Step 1. Prepare the first slurry. The raw materials for the first slurry include 20 parts of silicone rubber base glue, 6 parts of rosin resin, 1 part of nano-silica powder, 2 parts of nano-nylon powder, 2 parts of camellia oil, and 3 parts of thickening agent and 2 parts of coupling agent. Coat the first slurry on the release paper, and bake it at 70°C for 3 minutes to form a surface adhesive layer; then, use an aqueous solution of sodium alginate to repeat the hot-soaking and hot-pressing treatment for the surface adhesive layer three times: the first time: The hot-dipping temperature is 70°C, and the hot-dipping time is 6min; the hot-pressing temperature is 100°C, the hot-pressing pressure is 10MPa, and the hot-pressing time is 10min; Pressing temperature is 110°C, hot-pressing pressure is 12MPa, hot-pressing time is 13min; third time: hot-dipping temp...

Embodiment 2

[0030] A kind of preparation method of environment-friendly type silica gel synthetic leather, the step comprises

[0031] Step 1. Prepare the first slurry. The raw materials for the first slurry include 25 parts of silicone rubber base glue, 8 parts of rosin resin, 2 parts of nano-silica powder, 4 parts of nano-nylon powder, 3 parts of camellia oil, and 4 parts of thickening agent and 4 parts of coupling agent. Coat the first slurry on the release paper, and bake it at 80°C for 4 minutes to form a surface adhesive layer; then, use an aqueous solution of sodium alginate to repeat the hot-soaking and hot-pressing treatment on the surface adhesive layer three times: the first time: The hot-dipping temperature is 75°C, and the hot-dipping time is 7min; the hot-pressing temperature is 105°C, the hot-pressing pressure is 11MPa, and the hot-pressing time is 11min; Pressing temperature is 115°C, hot-pressing pressure is 13MPa, hot-pressing time is 14min; third time: hot-dipping temp...

Embodiment 3

[0036] A kind of preparation method of environment-friendly type silica gel synthetic leather, the step comprises

[0037] Step 1. Prepare the first slurry. The raw materials for the first slurry include 30 parts of silicone rubber base glue, 10 parts of rosin resin, 4 parts of nano silicon micropowder, 5 parts of nanometer nylon powder, 4 parts of camellia oil, and 5 parts of thickening agent and 6 parts of coupling agent. Coat the first slurry on the release paper, and bake it at 90°C for 5 minutes to form a surface adhesive layer; then, use an aqueous solution of sodium alginate to repeat the hot-soaking and hot-pressing treatment on the surface adhesive layer three times: the first time: The hot-dipping temperature is 80°C, and the hot-dipping time is 8min; the hot-pressing temperature is 110°C, the hot-pressing pressure is 12MPa, and the hot-pressing time is 12min; Pressing temperature is 120°C, hot-pressing pressure is 14MPa, hot-pressing time is 15min; third time: hot-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com