Wall-hung furnace and control method thereof

A control method and wall-hung boiler technology, applied to lighting and heating equipment, fluid heaters, etc., can solve the problems of relying on technical support personnel, increasing maintenance costs and time, and wasting human and financial resources, so as to avoid secondary failures and shorten Maintenance time and the effect of saving maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

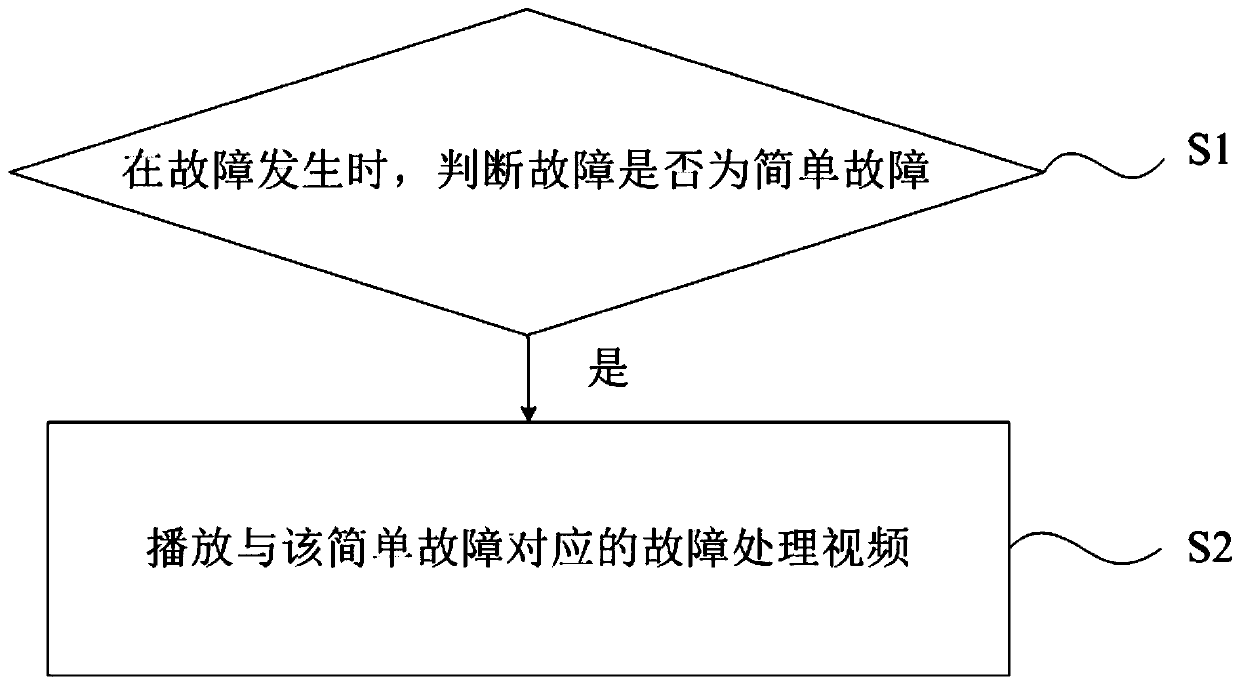

[0046] An embodiment of the present invention provides a control method for a wall-hung boiler, such as figure 1 As shown, the control method mainly includes:

[0047] Step S1: When a fault occurs, determine whether the fault is a simple fault;

[0048] During the normal use of the wall-hung boiler, it is inevitable that there will be operational failures. When a fault occurs, the wall-hung boiler stops working, and informs the user of the self-diagnosed fault type in the form of fault codes through the self-diagnosis program; it provides a basis for the user to take corresponding processing methods.

[0049] Considering that the structure and function of wall-hung boilers are different, the possible faults and maintenance methods will change accordingly. Which faults are simple faults may also change with the change of the group, but the faults that do not need to be disassembled for maintenance can be listed as Simple faults, because such simple faults can be handled by th...

Embodiment 2

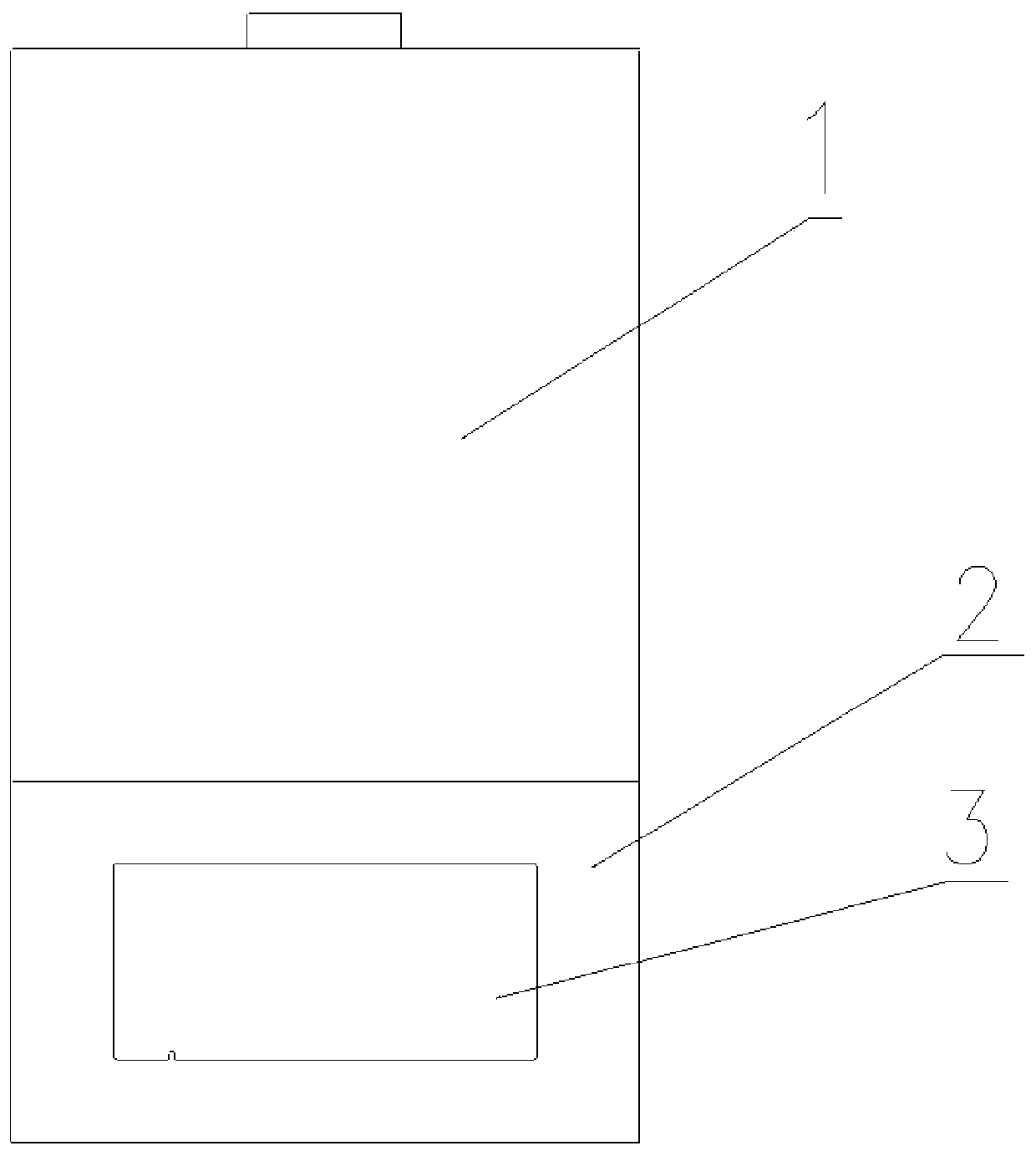

[0075] An embodiment of the present invention provides a wall-hung boiler, such as figure 2 As shown, it includes a wall-hung boiler body 1, a display panel 2 and a video player 3 arranged on the front of the wall-hung boiler body 1, and the video player 3 is arranged on the display panel 2, and also includes an electrical connection with the video player 3 to perform the above implementation. The controller for the control method in the example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com