Kalman filtering algorithm-based loader bucket stress testing method

A technology of Kalman filter and testing method, applied in the field of construction machinery testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0125] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

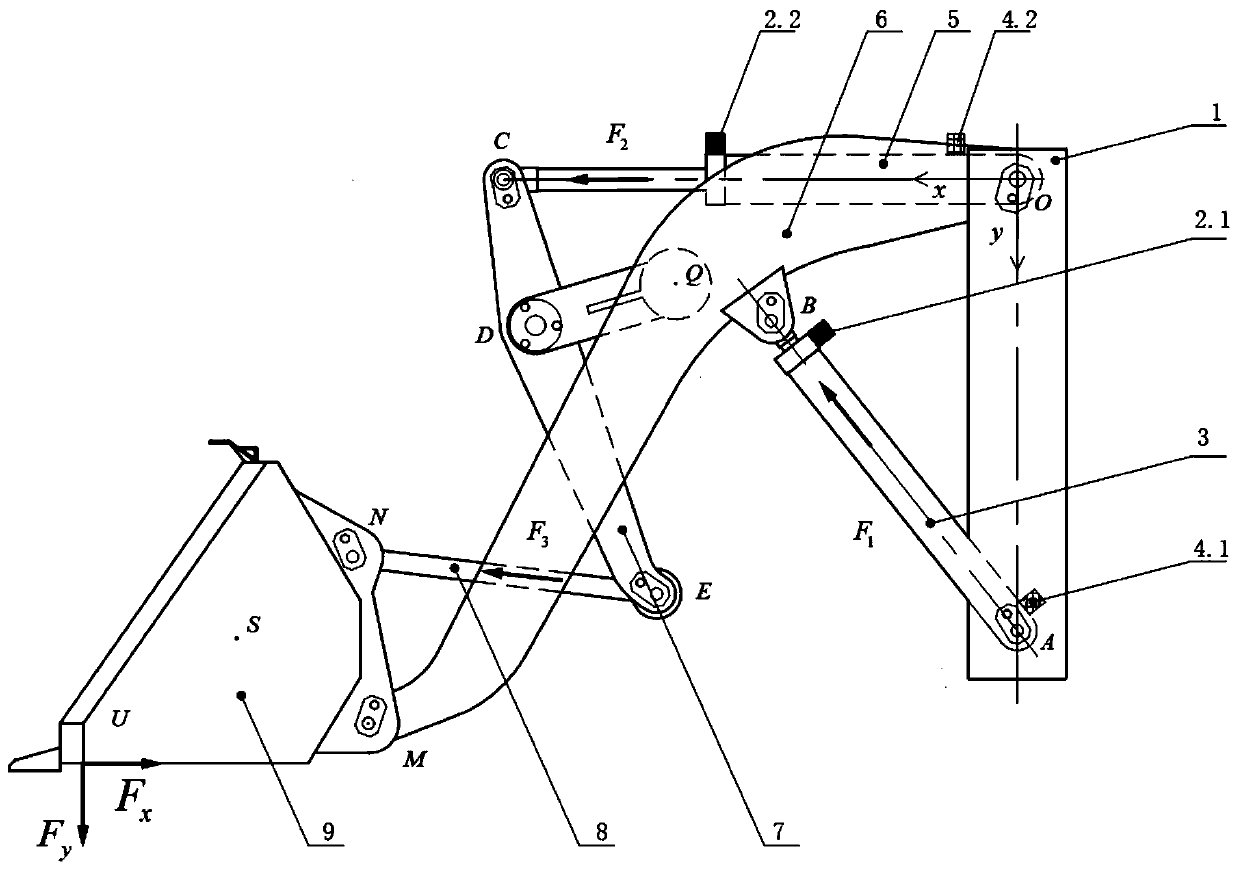

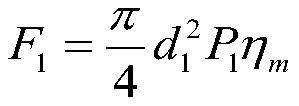

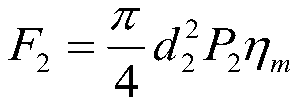

[0126] Such as figure 1 As shown, the loader bucket working device adopting the test method of the present invention is composed of a front frame 1, a boom 6, a boom cylinder 3, a rocker 7, a rocker cylinder 5, a connecting rod 8 and a bucket 9, Wherein, the cylinder end of the boom cylinder 3 is hinged with the bottom of the front frame 1, the push rod end of the boom cylinder 3 is hinged with the middle and upper part of the boom 6, and the rear end of the boom 6 is hinged with the top of the front frame 1 , the middle part of the boom 6 is hinged with the middle part of the rocker 7, the front end of the boom 6 is hinged with the rear side of the bucket 9, the cylinder end of the rocker cylinder 5 is hinged with the top of the front frame 1, and the rocker cylinder 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com