A pressure independent pressure making system

A technology of pressure and pre-pressure pumps, which is applied in the field of pressure building, and can solve problems such as process instability, high work intensity, and heavy manual labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

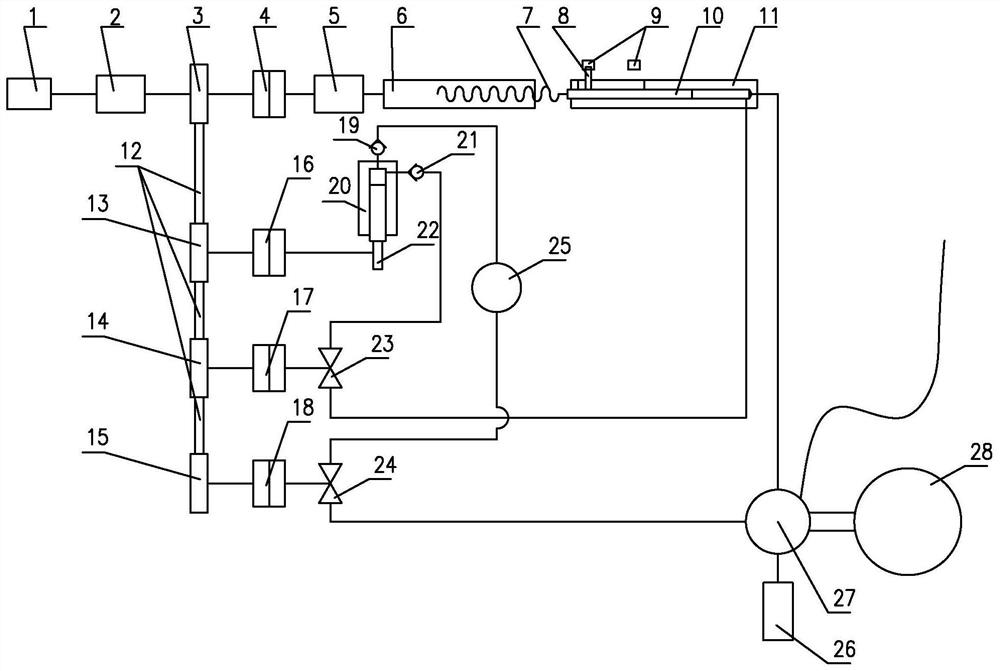

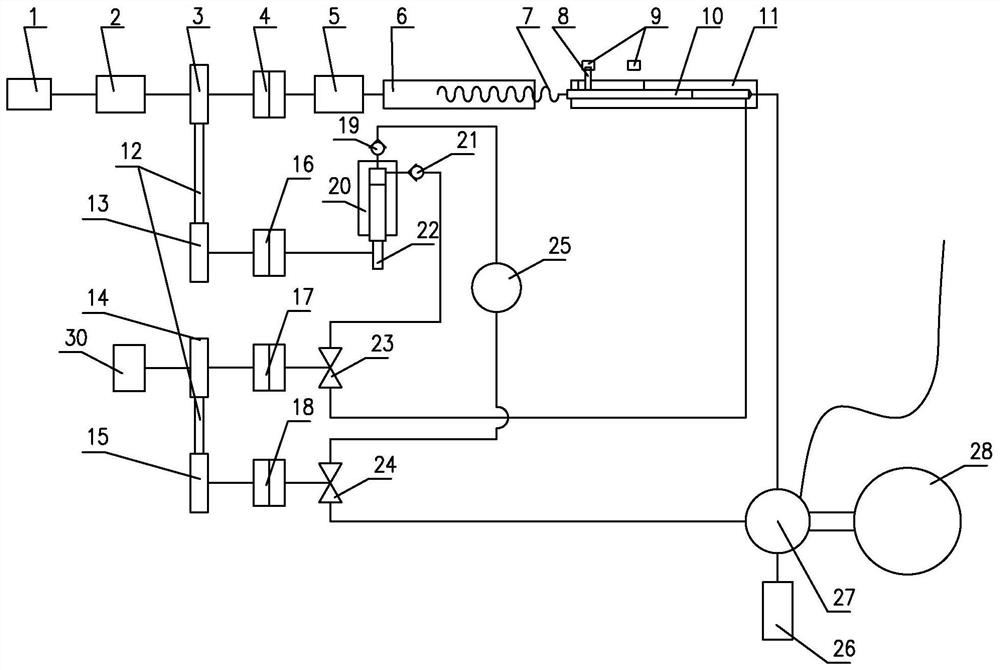

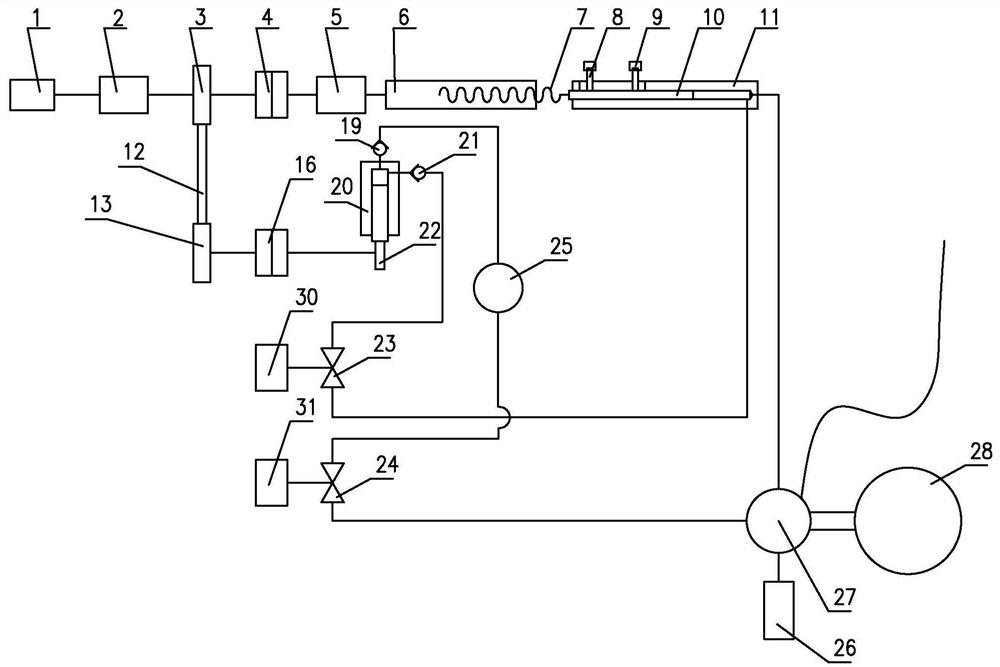

[0019] Such as figure 1 As shown, a servo motor-controlled pressure building system: the first servo motor 1 is connected to the first reducer 2, the speed of the first servo motor 1 is reduced to increase the torque, the first reducer 2 is connected to the transmission shaft, and the transmission The first sprocket 3 and the first clutch 4 are installed on the shaft to realize the transmission of rotating speed and torque. The first clutch 4 is connected with the second reducer 5 to reduce the speed of the first servo motor 1 and increase the torque. The second speed reducer 5 is connected with the screw sleeve 6, and the screw sleeve 6 cooperates with the screw rod 7, and the screw rod 7 is connected with the piston 10. The rotation of the first servo motor drives the piston 10 to move linearly in the piston cylinder 11, compressing the hydraulic oil in the piston cylinder 11 to realize the increase of pressure, the screw 8 is installed on the piston 10, the light shield is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com