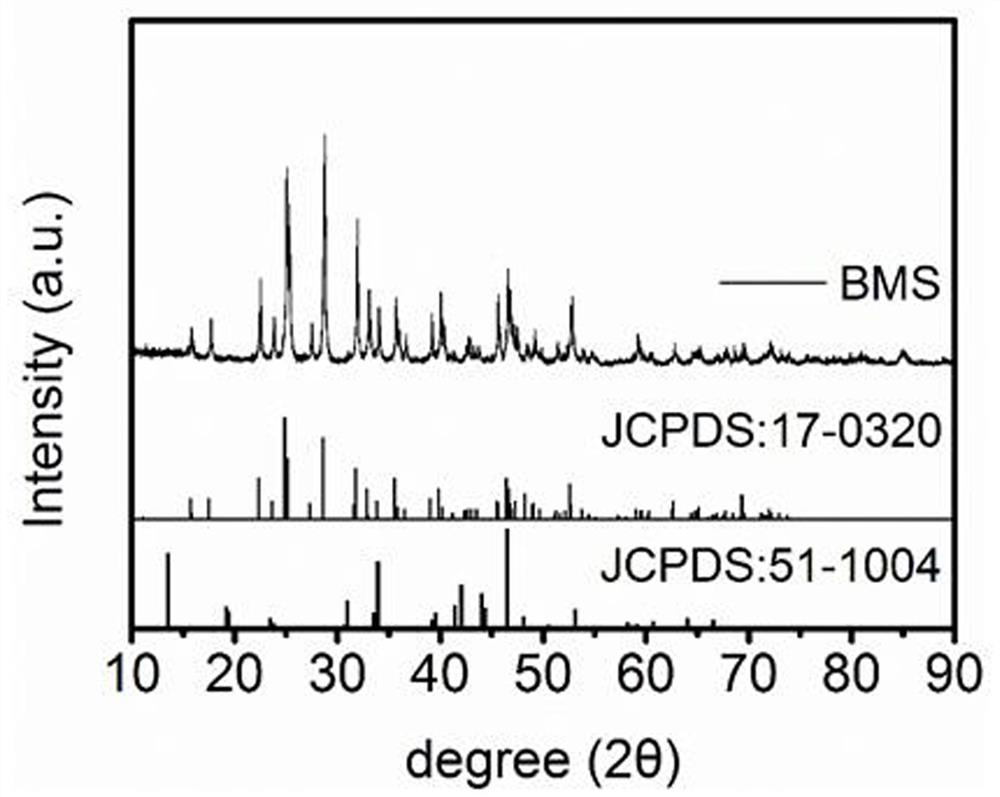

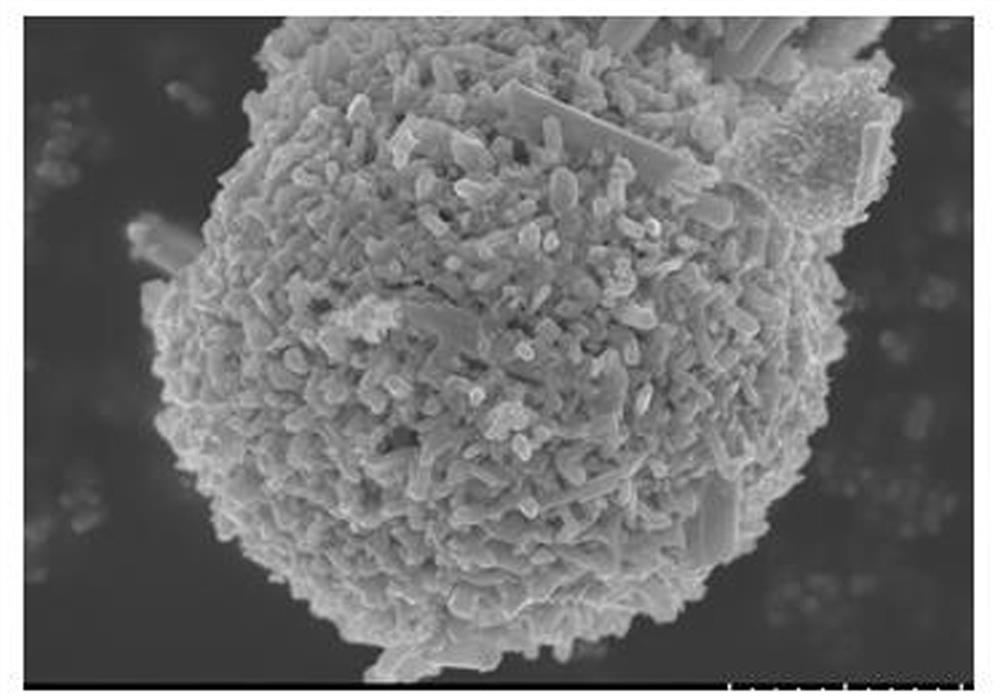

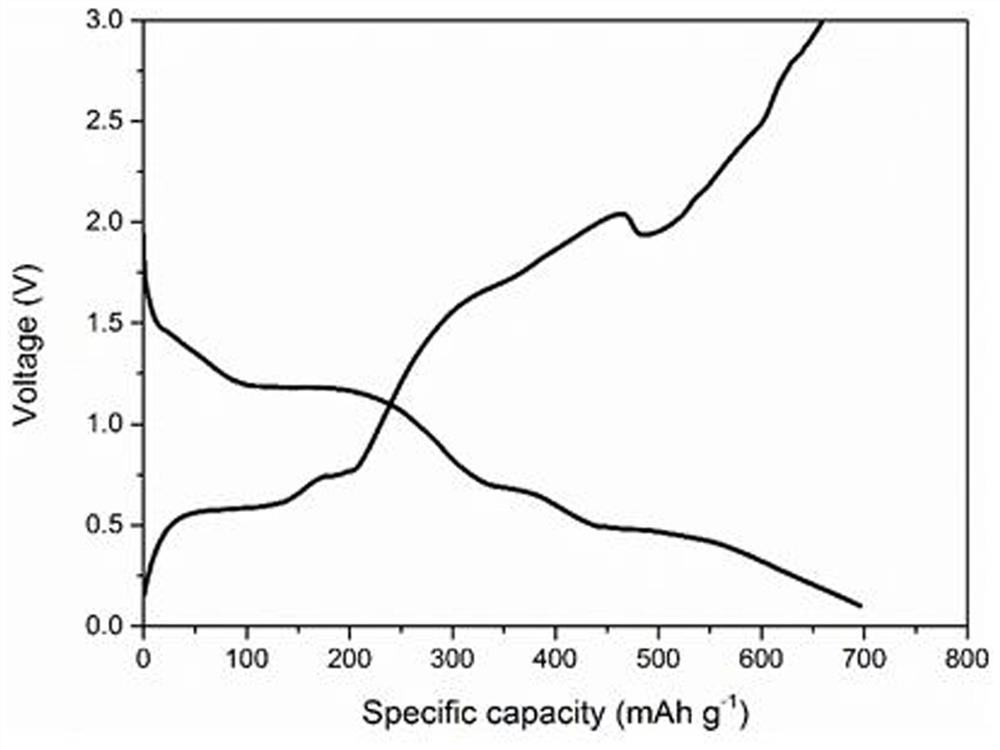

A kind of preparation method of bismuth molybdenum bimetallic sulfide of negative electrode material of sodium ion battery

A technology for sodium ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as poor cycle life and rapid capacity decay of sodium ion batteries, and achieve short process, uniform and controllable morphology, The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 1.57g of bismuth chloride and 0.511g of sodium molybdate, then add the weighed bismuth source and tin source to each beaker filled with ethylene glycol (7mL), stir magnetically at room temperature until the particles are completely dissolved , mixing the ethylene glycol solution dissolved with the bismuth source and the molybdenum source, and magnetic stirring at room temperature to form a uniform mixed solution;

[0031] (2) Add absolute ethanol (25mL) to the mixed solution obtained in step (1), stir evenly at room temperature, and then place it in a 100mL polytetrafluoroethylene reactor for high-temperature solvothermal reaction. The reaction temperature is 150°C. The time is 12 hours;

[0032] (3) The product after the high-temperature solvothermal reaction in step (2) was centrifuged and washed 6 times (3 times each with absolute ethanol and deionized water), and dried at 80°C for 16 hours to obtain a yellow-brown bismuth-molybdenum oxide precursor ;

[...

Embodiment 2

[0037] (1) Weigh 3.17g of bismuth chloride and 1.021g of sodium molybdate, then add the weighed bismuth source and tin source to each beaker filled with ethylene glycol (8mL), stir magnetically at room temperature until the particles are completely dissolved , mixing the ethylene glycol solution dissolved with the bismuth source and the molybdenum source, and magnetic stirring at room temperature to form a uniform mixed solution;

[0038] (2) Add absolute ethanol (25mL) to the mixed solution obtained in step (1), stir evenly at room temperature, and then place it in a 100mL polytetrafluoroethylene reactor for high-temperature solvothermal reaction. The reaction temperature is 150°C. The time is 12 hours;

[0039] (3) The product after the high-temperature solvothermal reaction in step (2) was centrifuged and washed 6 times (3 times each with absolute ethanol and deionized water), and dried at 90°C for 12 hours to obtain a yellow-brown bismuth-molybdenum oxide precursor ;

[...

Embodiment 3

[0044] (1) Weigh 1.57g of bismuth chloride and 0.511g of sodium molybdate, then add the weighed bismuth source and tin source to each beaker filled with ethylene glycol (7mL), stir magnetically at room temperature until the particles are completely dissolved , mixing the ethylene glycol solution dissolved with the bismuth source and the molybdenum source, and magnetic stirring at room temperature to form a uniform mixed solution;

[0045] (2) Add absolute ethanol (30mL) to the mixed solution obtained in step (1), stir evenly at room temperature, and then place it in a 100mL polytetrafluoroethylene reactor for high-temperature solvothermal reaction. The reaction temperature is 150°C. The time is 12 hours;

[0046] (3) The product after the high-temperature solvothermal reaction in step (2) was centrifuged and washed 6 times (3 times each with absolute ethanol and deionized water), and dried at 100°C for 24 hours to obtain a yellow-brown bismuth-molybdenum oxide precursor ;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com