Calorimetric probe and a method for calorimetric measurement

A probe, calorimetric technology, applied in the field of calorimetric probes, can solve the impossible to obtain reliable results and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

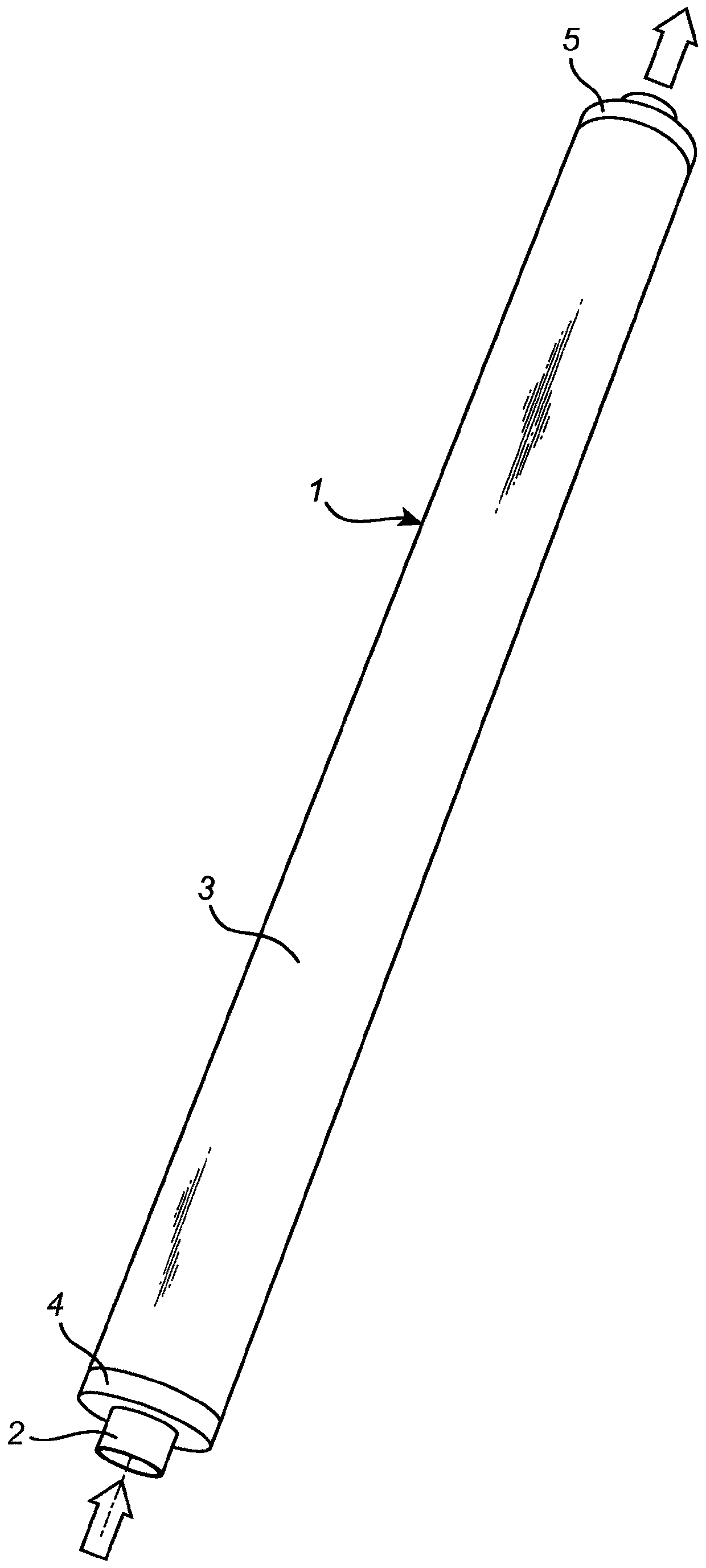

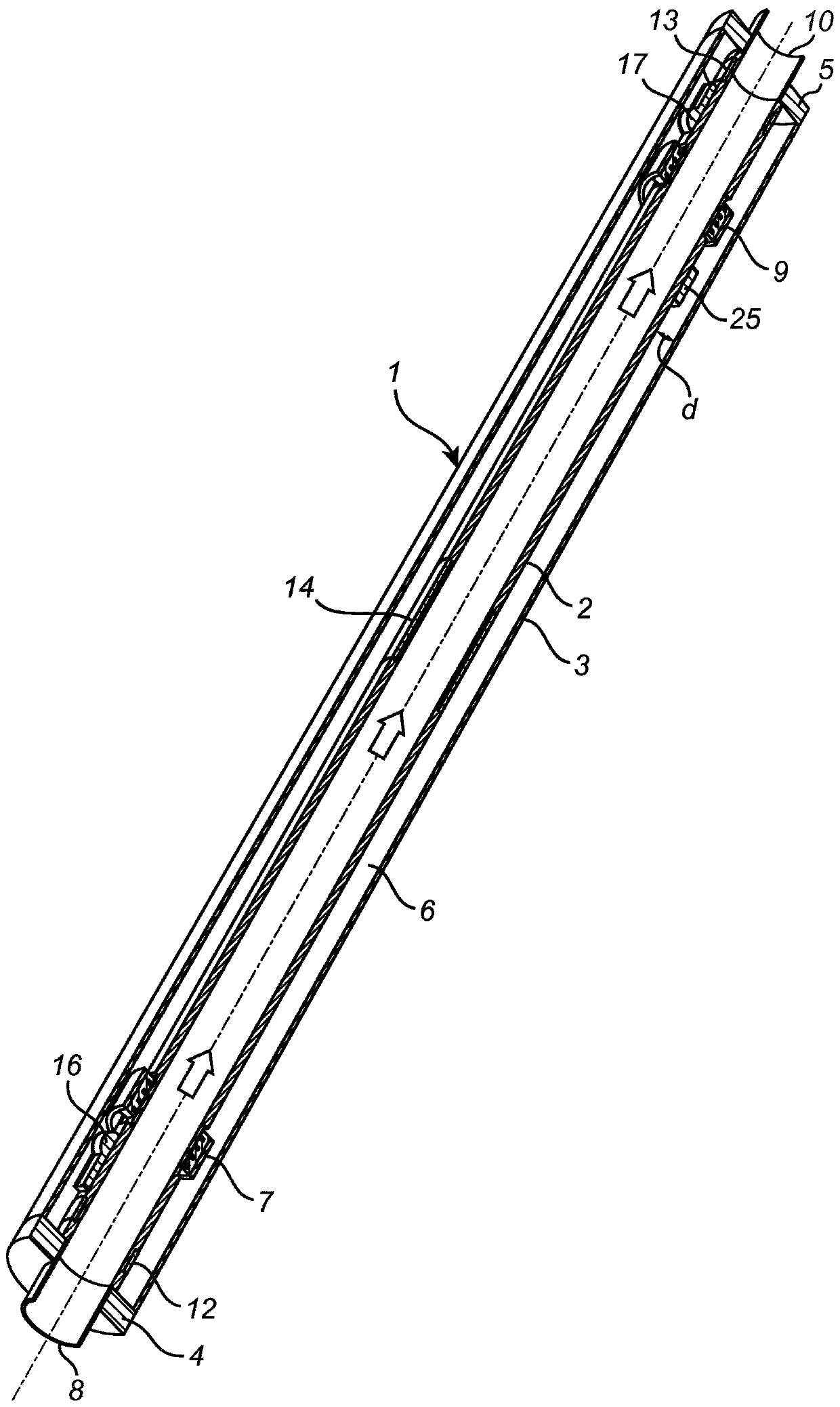

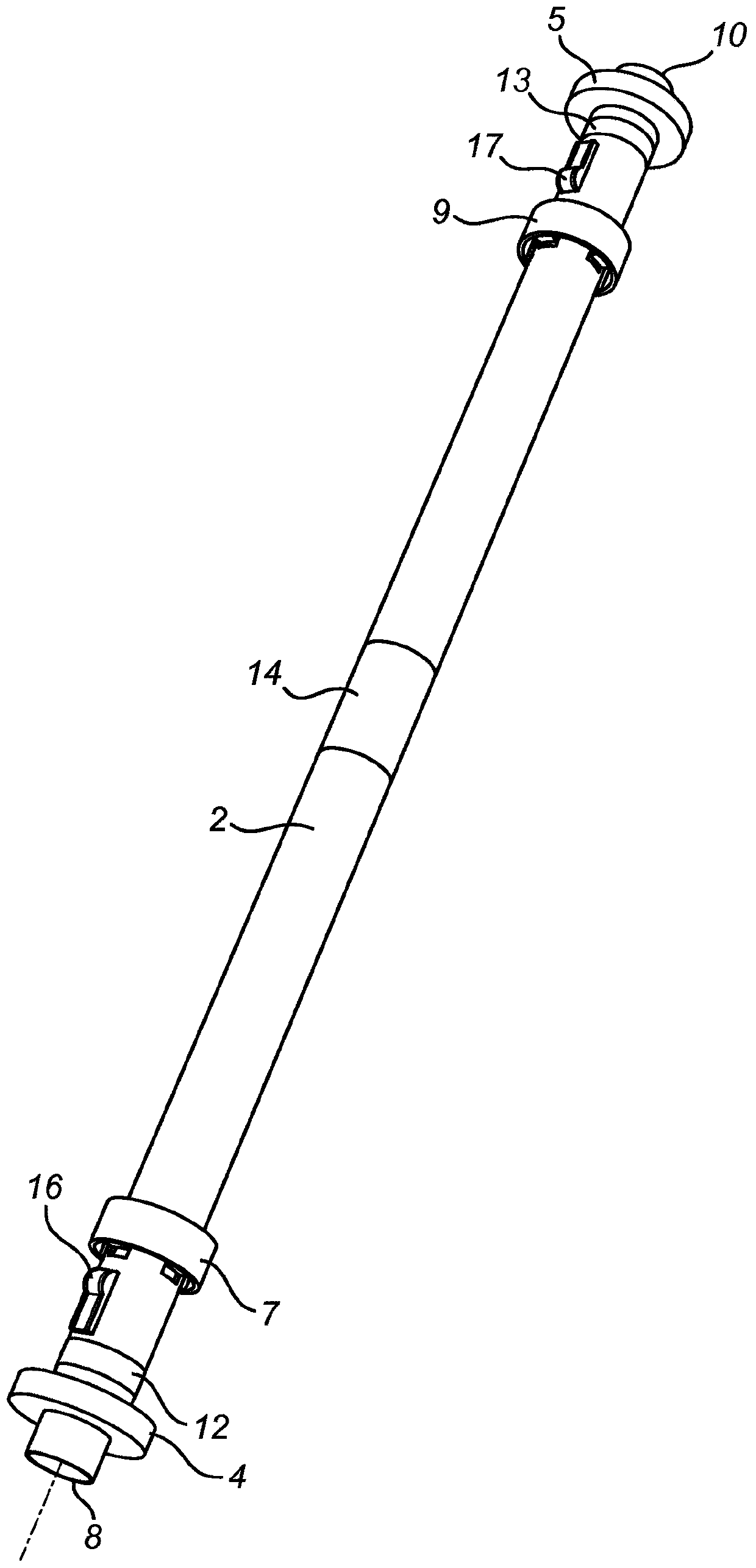

[0030] A first embodiment of a reaction calorimeter probe 1 generally comprises an inner tube 2 arranged to have a pumpable reaction medium flowing through the inner tube 2, for example by figure 1 and the outer tube 3 extending coaxially with the inner tube 2 at a radial distance d from the inner tube 2 . The end opening of the outer tube 3 is sealed by a sealing first cap 4 and a second cap 5 . Thus, a sealed space 6 is provided between the inner tube 2 and the outer tube 3 . This structure of the inner and outer tubes and other components therein, which will be described hereinafter, will also be referred to herein as the tubular component 15 of the reaction calorimeter probe 1 . Space 6 is set to vacuum, that is, space 6 has been evacuated to a very low pressure, preferably below 10 -6 bar, and more preferably below 10 -8 bar. In any case, the evacuation of the air should reach a pressure level in which the thermal conductivity in the space 6 is significantly reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com