Current collector, electrode, and non-aqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in the direction of non-aqueous electrolyte batteries, non-aqueous electrolyte battery electrodes, secondary batteries, etc., to achieve the effect of increasing resistance and suppressing thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

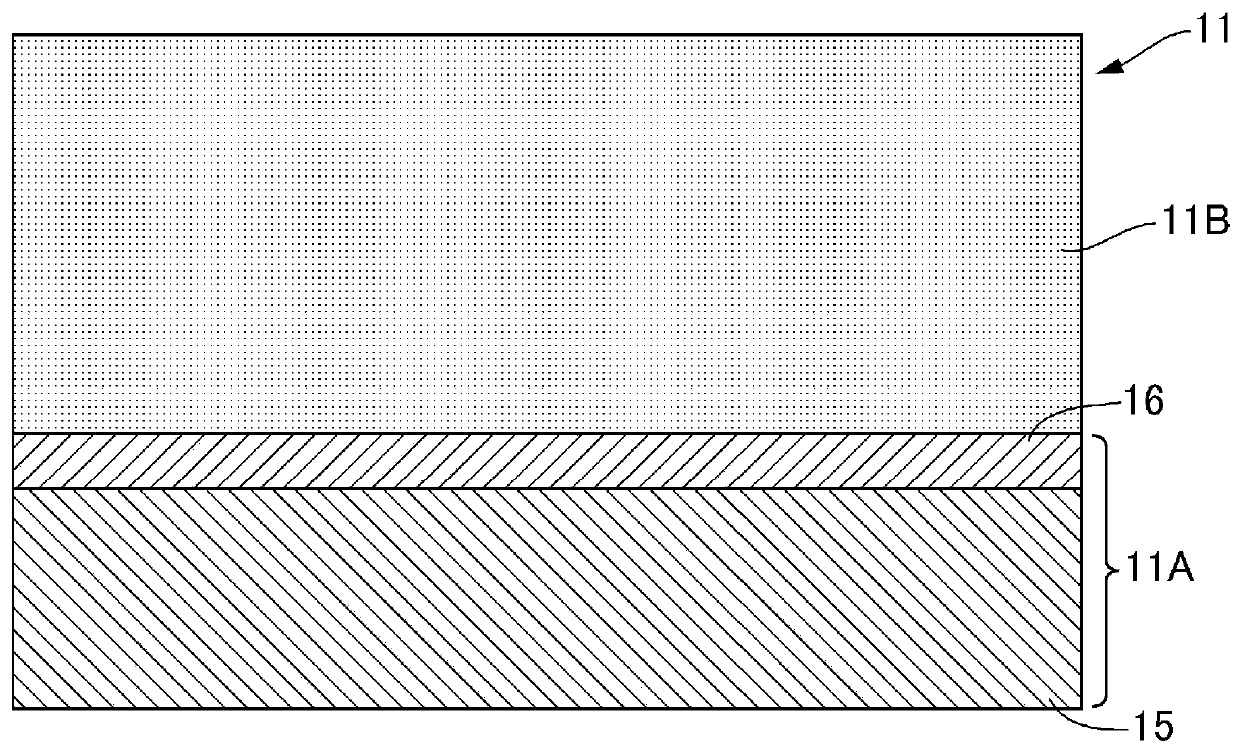

[0163] Production of PTC layer

[0164] 1. Slurry Preparation

[0165] For slurry preparation, a 5 L planetary mixer was used.

[0166] 900 g of flaky graphite (manufactured by TIMICAL, with an average particle diameter of 2 μm) and 25 g of Super-P (conductive carbon manufactured by TIMCAL) were mixed for 10 minutes, and then 200 g of N-methylpyrrolidone (NMP) was added, and further carried out for 20 minutes. minutes to mix.

[0167] Next, 62.5 g of a mixed liquid (BX1) obtained by dissolving 40 g of a mixture of BMI-1000 / BTA=2 / 1 in 1,000 g of NMP, and 8%-PVDF solution (dissolving PVDFW#7200 manufactured by KUREHA in NMP )62.5g, NMP1000g, kneading for 60 minutes. The solid content concentration at this time was 43% (1000 g of solid content, 1317.5 g of NMP).

[0168] Furthermore, NMP 1000g was added, and kneading was performed for 60 minutes (30% of solid content concentration).

[0169] Then, in order to adjust the viscosity, 682.5 g of NMP was added and mixed for 30 ...

Embodiment 2~24

[0207] It should be noted that in Table 6, the PTC layers shown in PTC2 to 24 were produced in the following manner: according to Example 1, the mixture with the PTC function-imparting component and PVDF (PVDFW#7200 manufactured by KUREHA) were replaced with Except the combination shown in Table 6, it carried out similarly to Example 1, and in Examples 2-24, positive electrodes C-2-24 which arrange|positioned these PTC layers were produced.

Embodiment 25~28

[0209] In addition, in Table 6, the PTC layers shown in PTC-25 to PTC-28 were prepared as follows: According to Example 1, instead of the mixture with the PTC function-imparting component and PVDF (KUREHA PVDFW#7200), The PTC layer was fabricated using a binder liquid obtained by dissolving PVDF-HFP copolymer in NMP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com