Dry ice type inert gas making cooling type fuel tank inerting system

A technology of air cooling and dry ice, which is applied in the field of aviation systems, can solve the problems of large structural weight and high manufacturing cost, and achieve the effect of no compensation loss and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

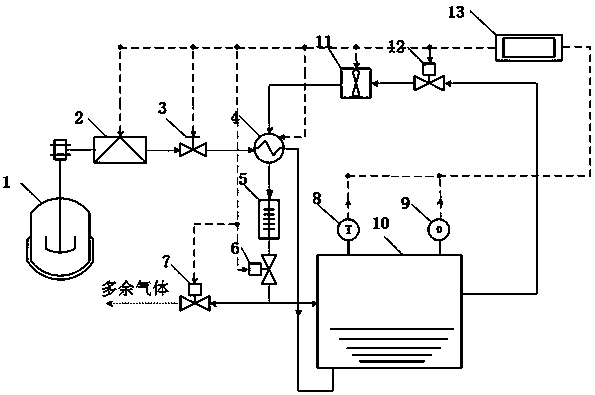

[0021] The embodiment of the present invention provides a dry ice-based inert gas-cooled fuel tank inerting system, such as figure 1 Shown, including: dry ice storage tank 1, pressure regulating valve 2, stop valve 3, heat exchanger 4, dryer 5, first electric regulating valve 6, second electric regulating valve 7, temperature sensor 8, oxygen concentration sensor 9 , Fan 11, third electric regulating valve 12, controller 13.

[0022] The fuel tank 10 has two inlet ports and one outlet port. The probes of the oxygen concentration sensor 9 and the temperature sensor 8 extend into the upper space of the oil tank 10 to be operated to detect the oxygen concentration and temperature of the upper part of the oil tank 10.

[0023] The cold side inlets of the dry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com