Intelligent workshop combined scheduling control method

A scheduling control and workshop technology, applied in the field of intelligent workshop combined scheduling control, can solve the problems of high time cost, simultaneous production performance and scheduling real-time performance, poor optimization performance, etc., achieve low time complexity, shorten evolution time, The effect of shortening the evaluation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

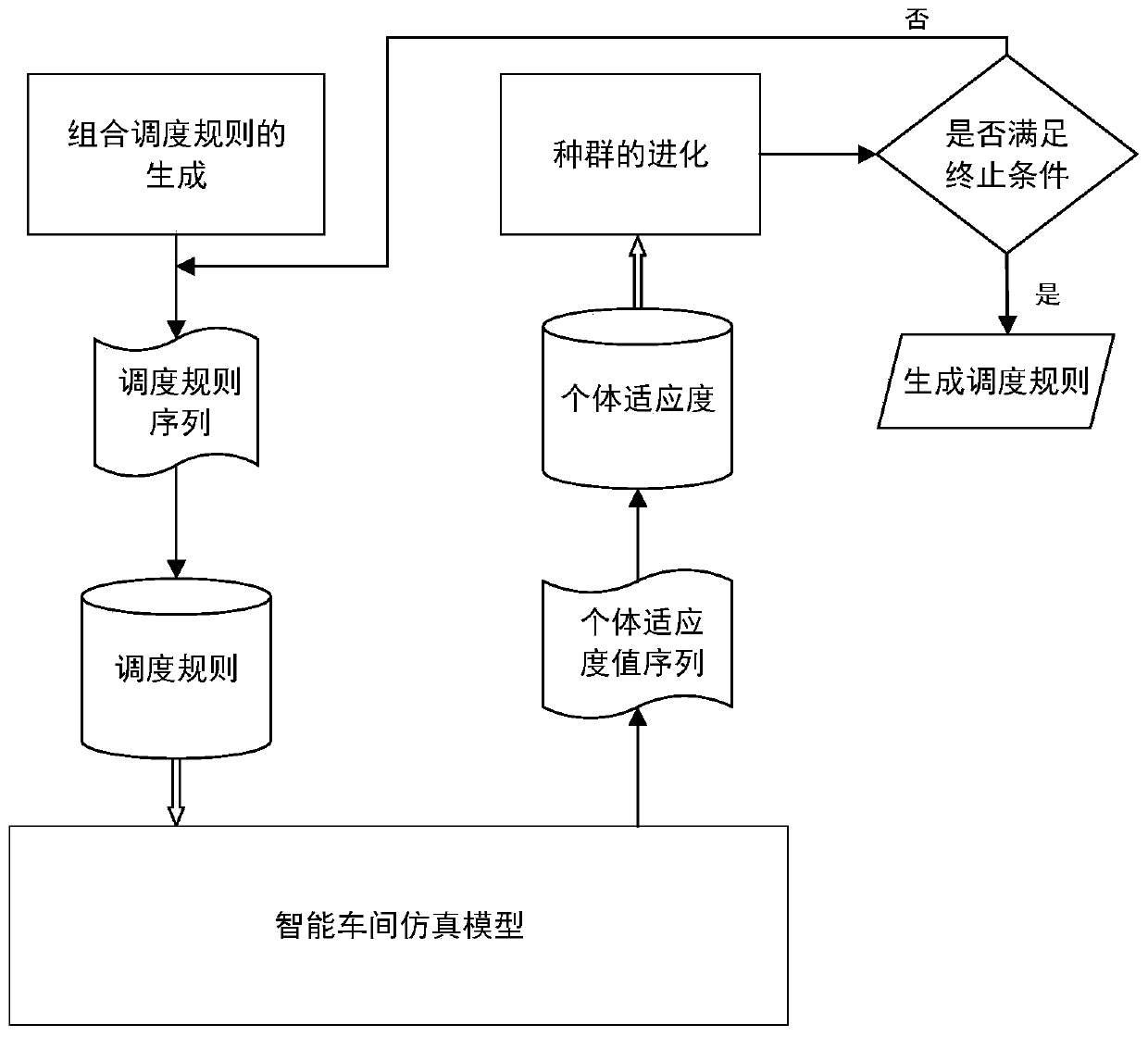

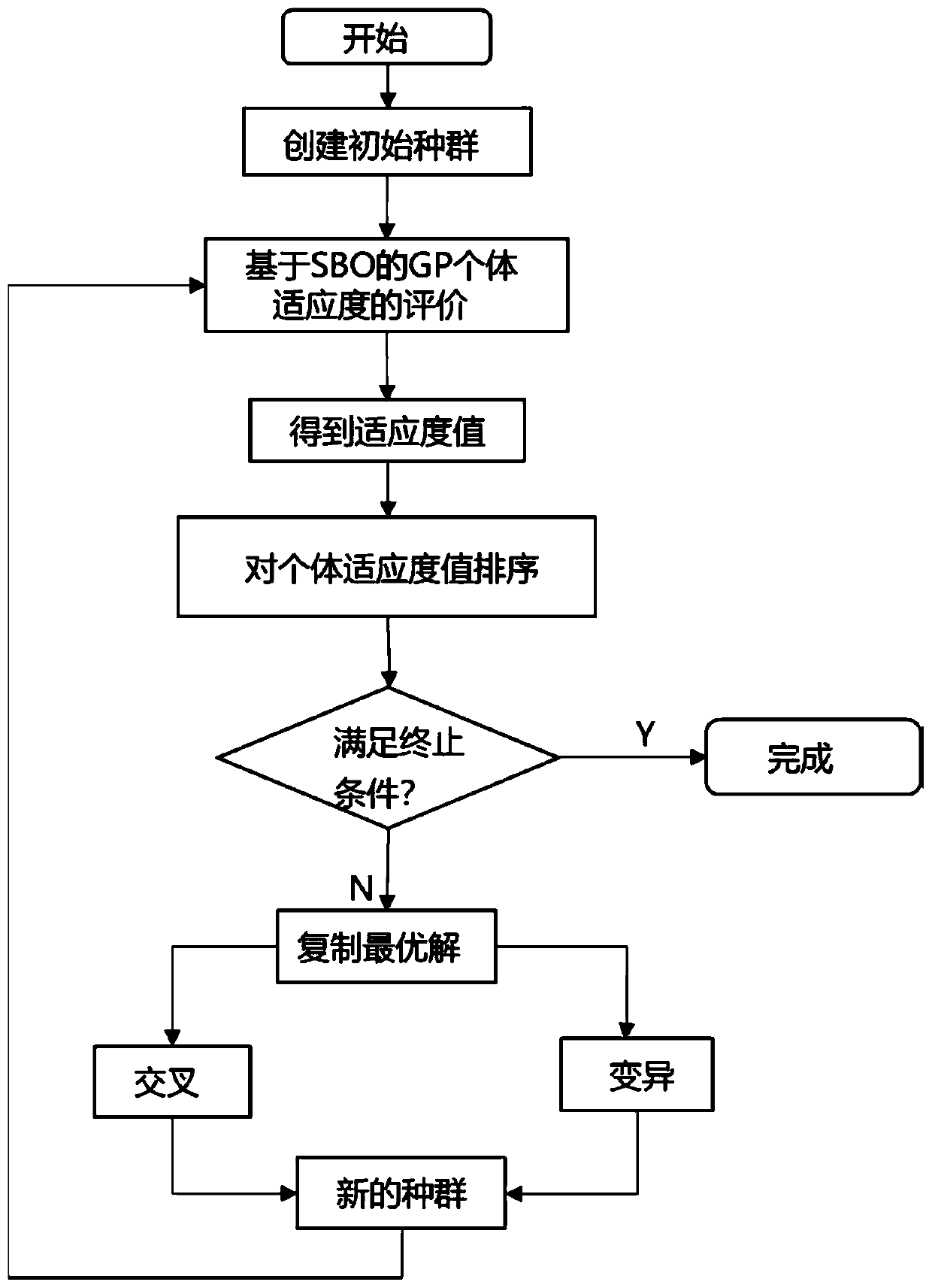

[0053] as attached figure 1 As shown, a method for mining intelligent workshop combination scheduling rules, including the following steps:

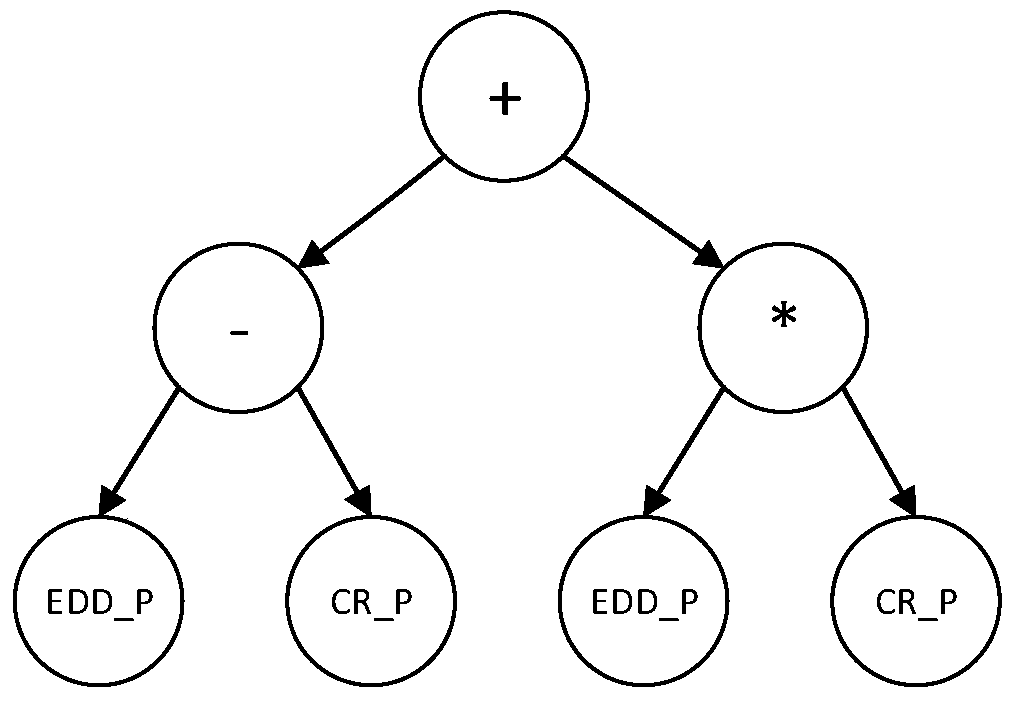

[0054] 1) Use a tree structure to form a new combined scheduling rule, and determine the elements of the combined scheduling rule, including the terminator set and the function set. The new combined dispatching rule constituted by a tree structure refers to a dispatching rule constituted in the form of a binary tree. The terminator set refers to the leaf nodes of the binary tree constituting the scheduling rule. The simple heuristic rules are normalized, and the normalized simple heuristic rules are used as the terminator set. The function set refers to the non-leaf nodes of the binary tree constituting the scheduling rule. Including addition, subtraction, multiplication, division, tangent, sine, cosine, maximum, minimum functions and other basic operation functions. The process of normalizing simple heuristic rules is as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com