Immersed liquid cooling refrigerant filtering system

A filter system and immersion technology, applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of expensive, rapid and easy evaporation loss of electronic fluorinated fluid, etc., and achieve easy operation and maintenance, and extended The effective working time and the effect of enhancing the boiling heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

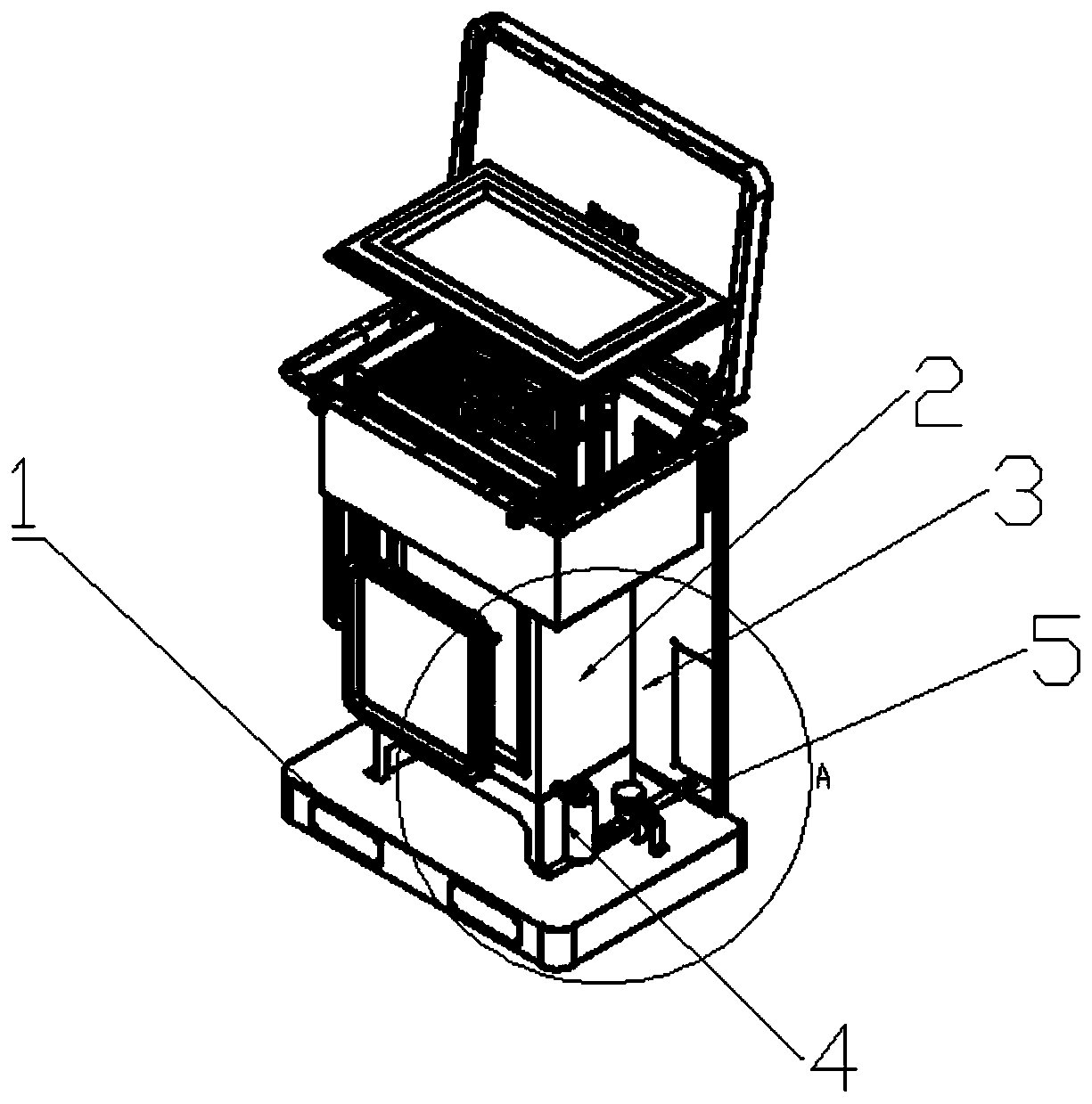

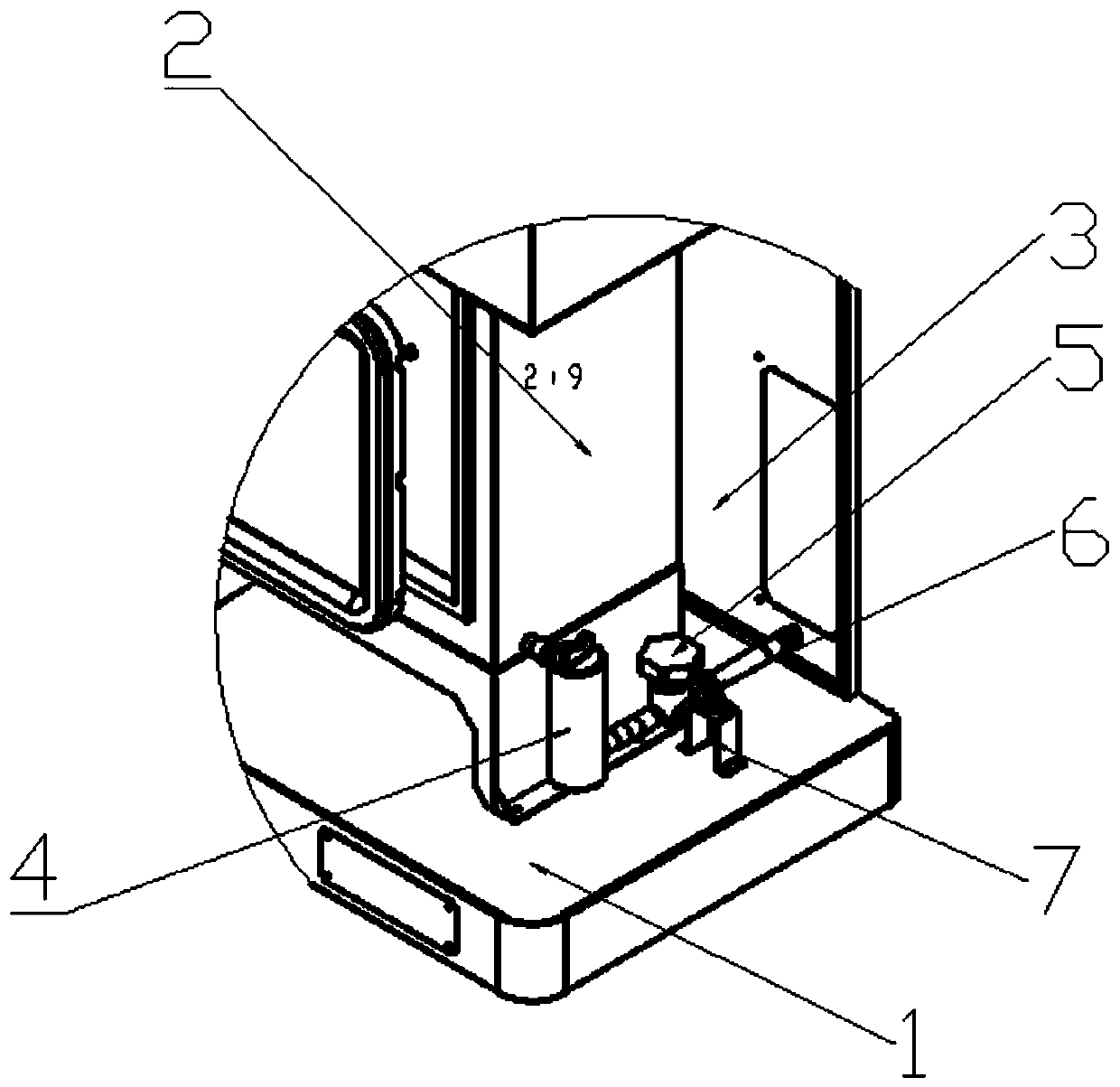

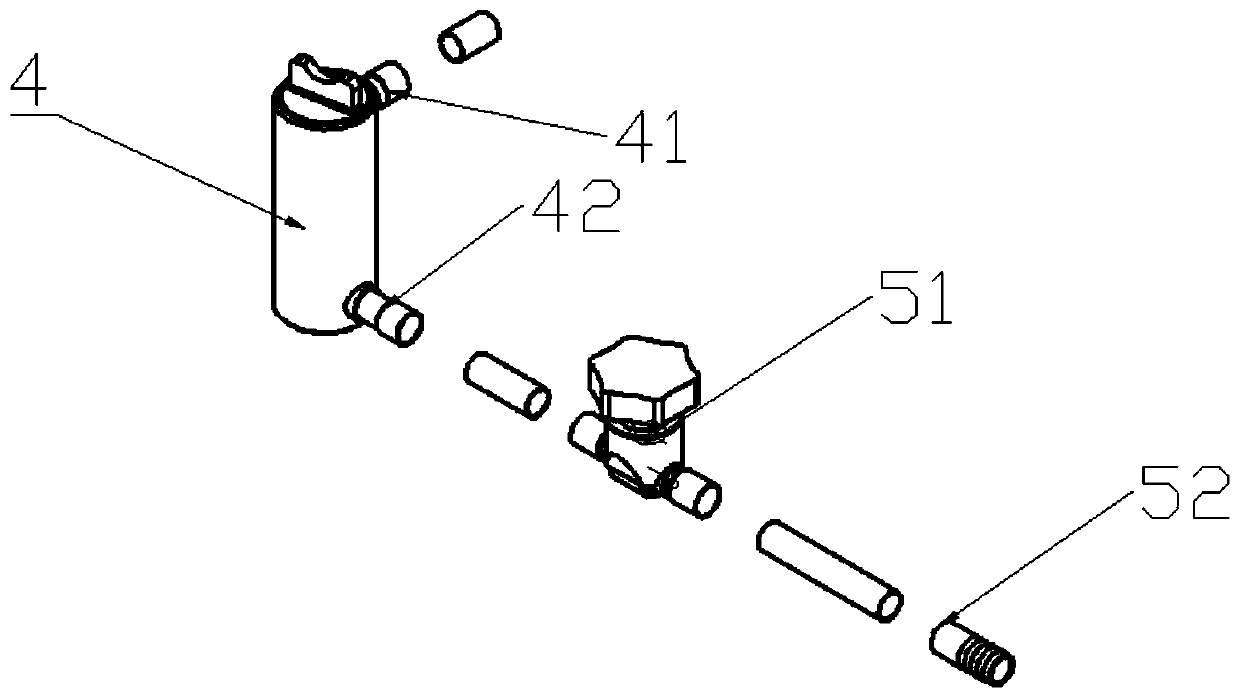

[0030] see Figure 1-4 As shown, the present invention discloses a submerged liquid-cooled refrigerant filtering system, comprising a base 1, an inner oil tank 2, a rear door panel 3, a filter 4 and an oil discharge pipe assembly 5;

[0031] The inner oil tank 2 is a metal inner oil tank 2 with a visual window; the working state is more controllable; it is composed of a stainless steel welded metal frame and a tempered glass sealing strip screwed together to meet the performance requirements of high temperature resistance and corrosion resistance, High temperature and oil resistant soft sealant is filled between the stainless steel welded metal frame and the tempered glass sealing strip to ensure its absolute sealing performance. The inner fuel tank 2 is fixed on the base 1;

[0032] The rear door panel 3 is a detachable metal cover plate, and the bottom is movably connected with the bottom plate of the outer box through a latch; it is convenient for maintenance, locking and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com