liquid container

A liquid container and tank technology, which is applied in the field of liquid containers to prevent electrochemical corrosion, can solve the problems of weakening the protective effect of the pressure container and reducing the protective current, and achieves the effects of improving the production and operation efficiency, stabilizing the work, and prolonging the maintenance period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

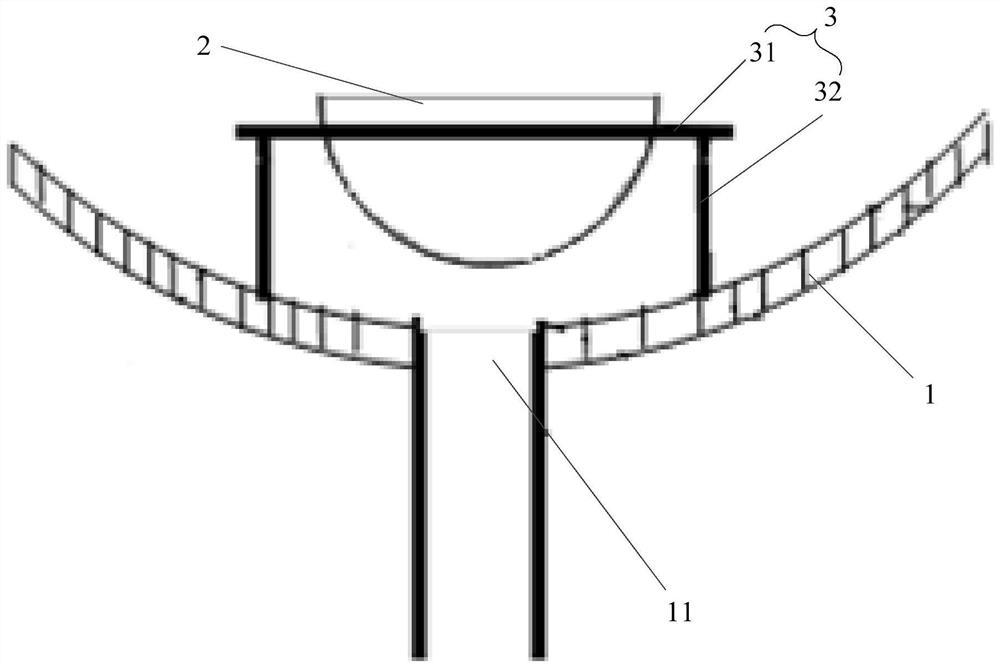

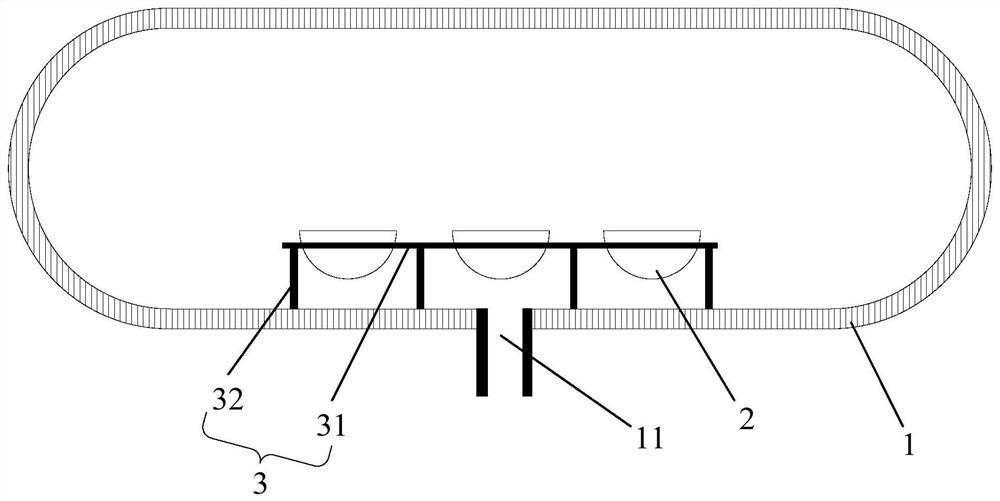

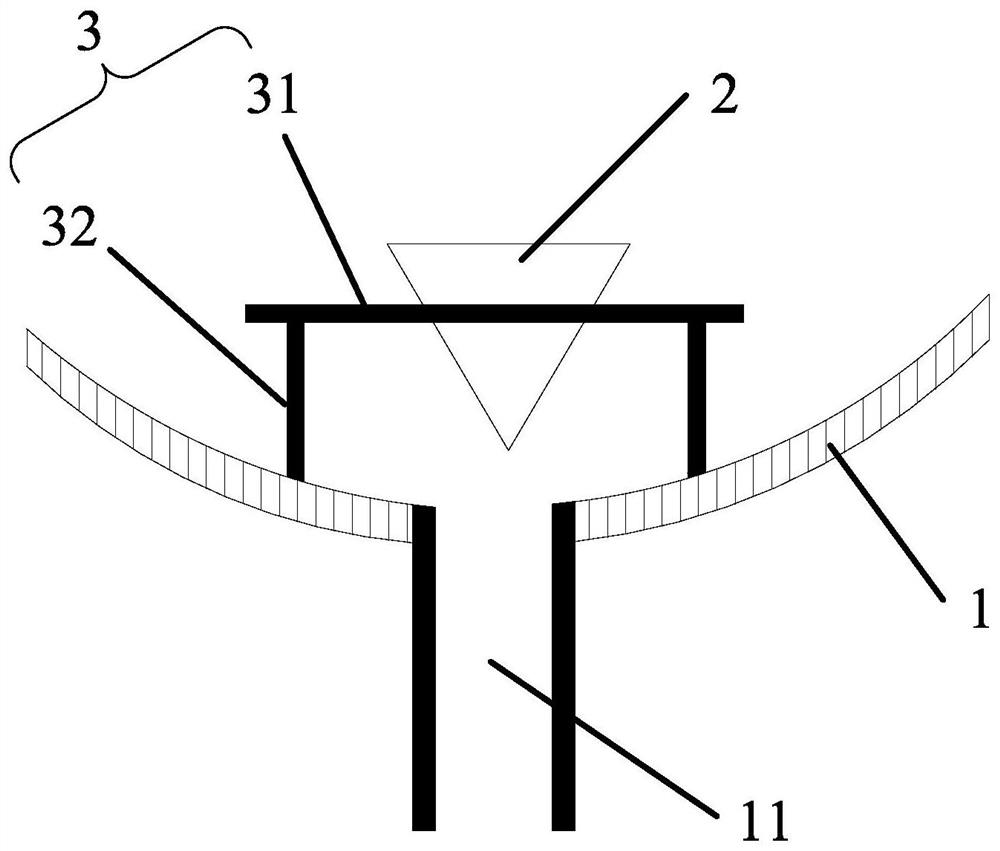

Image

Examples

Embodiment Construction

[0033] At present, in the production of oil and natural gas, pressure vessels are indispensable equipment, especially in the process of oil and natural gas gathering, transportation and processing, in the process of separating oil and gas and removing impurities such as water in oil and gas. A pressure vessel is required. Since the extracted oil and natural gas contain water, sulfide and other corrosive substances, when the pressure vessel is used for processing, the above-mentioned corrosive substances will cause electrochemical corrosion to the inner surface of the pressure vessel, and in severe cases, it will affect Safe use of pressure vessels.

[0034] In the prior art, the method of setting sacrificial anodes in the pressure vessel is usually used to prevent electrochemical corrosion. The principle is to use the corrosive aqueous solution contained in oil and natural gas as an electrolyte, and act on the surface of the sacrificial anode to continuously lose electrons. ,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap