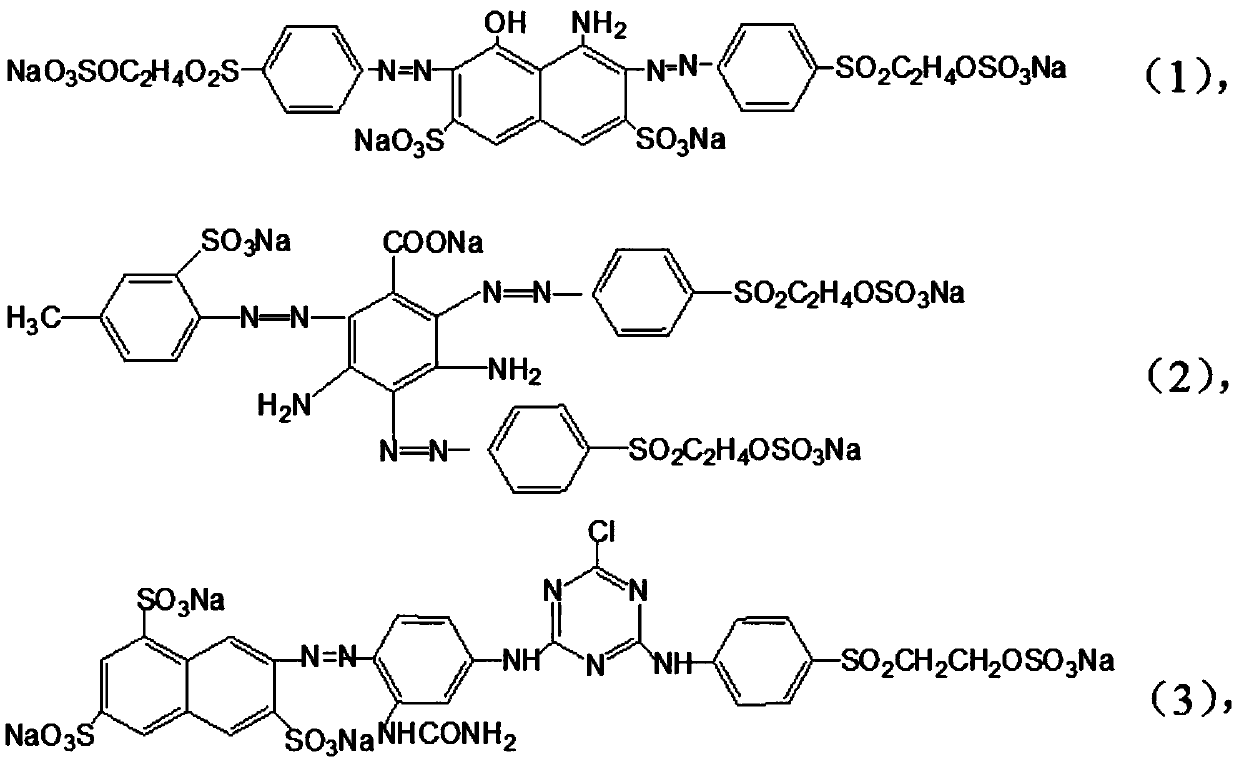

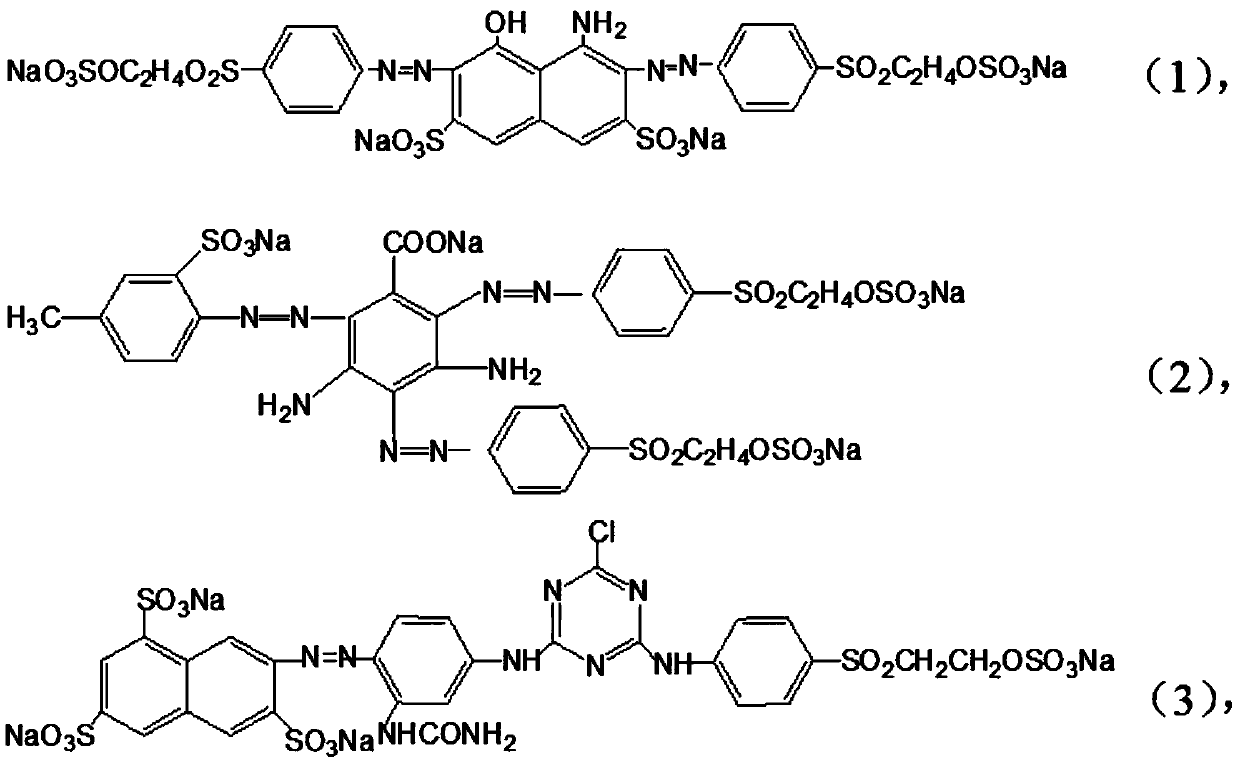

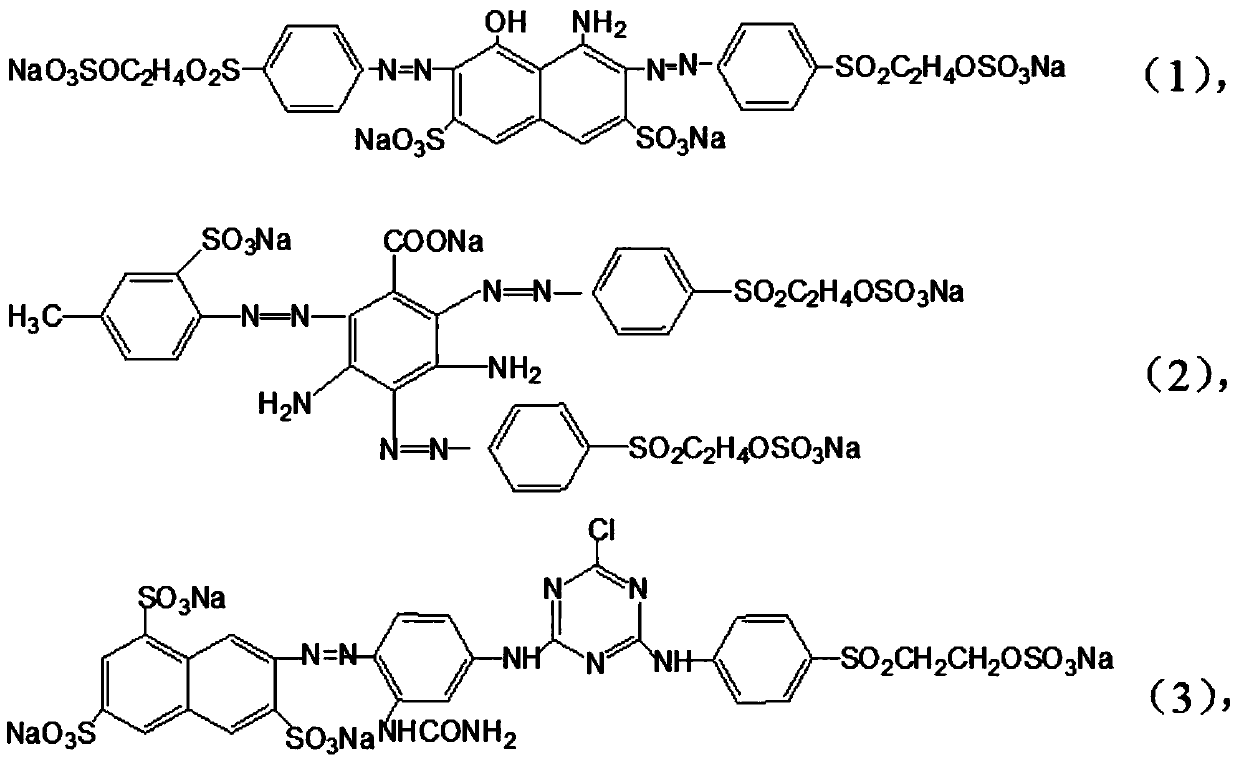

Compound reactive black dye and application thereof

A technology of reactive black and black dyes, applied in the field of composite reactive black dyes, which can solve the problems of color sticking, poor washing performance, low color fixation rate and low dyeing depth, reduce production costs, increase washing performance, and reduce dyeing dyes volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Mix 80 parts of the dye of formula (1), 20 parts of the dye of formula (2) and 1 part of the dye of formula (3) and fully mechanically mix to obtain the composite reactive black dye of the present invention. High level dyeing property, high color fixation rate, high jet black fullness and good deep dyeing black.

[0037] Exhaust dyeing: Dissolve 1g of the dye prepared in Example 1 with an appropriate amount of water, then set the volume in a 250mI volumetric flask, absorb 50mI of the dye solution and mix it with 50mI of water, then add 5g of cotton cloth and 6g of sodium sulfate. Then increase the temperature to 60°C at a rate of 1°C / min, keep it for 30 minutes, add 2g of sodium carbonate, and keep it at 60°C for 30 minutes, then take out the dyed cotton cloth and boil it with non-ionic detergent boiling soap for 15 minutes, then wash it with water and dry it. Dry at around 70°C.

[0038] Resist printing: Sprinkle 3 parts of the dyes obtained in Example 1 into 100 part...

Embodiment 2

[0040] Mix 70 parts of the dye of formula (1), 25 parts of the dye of formula (2) and 5 parts of the dye of formula (3) and then fully mechanically mix to obtain the composite reactive black dye of the present invention. High level dyeing property, high color fixation rate, high jet black fullness and good deep dyeing black.

[0041] Exhaust dyeing: first fully dissolve 1g of the dye prepared in Example 2 with an appropriate amount of water, then set the volume in a 250ml volumetric flask, absorb 50ml of the dye solution and mix it with 50ml of water, then add 5g of cotton cloth and 6g of sodium sulfate. Then increase the temperature to 60°C at a rate of 1°C / min, keep it for 30 minutes, add 2g of sodium carbonate, and keep it at 60°C for 30 minutes, then take out the dyed cotton cloth and boil it with non-ionic detergent boiling soap for 15 minutes, then wash it with water and dry it. Dry at around 70°C.

[0042]Resist printing: Sprinkle 2 parts of the dyes obtained in Exampl...

Embodiment 3

[0044] Mix 60 parts of the dye of formula (1), 35 parts of the dye of formula (2) and 5 parts of the dye of formula (3) and then fully mechanically mix to obtain the composite reactive black dye of the present invention. High level dyeing property, high color fixation rate, high jet black fullness and good deep dyeing black.

[0045] Exhaust dyeing: first fully dissolve 1g of the dye prepared in Example 3 with an appropriate amount of water, then set the volume in a 250mI volumetric flask, absorb 50mI of the dye solution and mix it with 50mI of water, then add 5g of cotton cloth and 6g of sodium sulfate. Then increase the temperature to 60°C at a rate of 1°C / min, keep it for 30 minutes, add 2g of sodium carbonate, and keep it at 60°C for 30 minutes, then take out the dyed cotton cloth and boil it with non-ionic detergent boiling soap for 15 minutes, then wash it with water and dry it. Dry at around 70°C.

[0046] Resist printing: Sprinkle 3 parts of the dyes obtained in Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com