High-performance flame-retardant UV paint production process

A production process and high-performance technology, which is applied in the field of UV paint, can solve the problems such as the unsatisfactory flame retardant effect, and achieve the effect of improving the flame retardant effect, good combination effect, and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

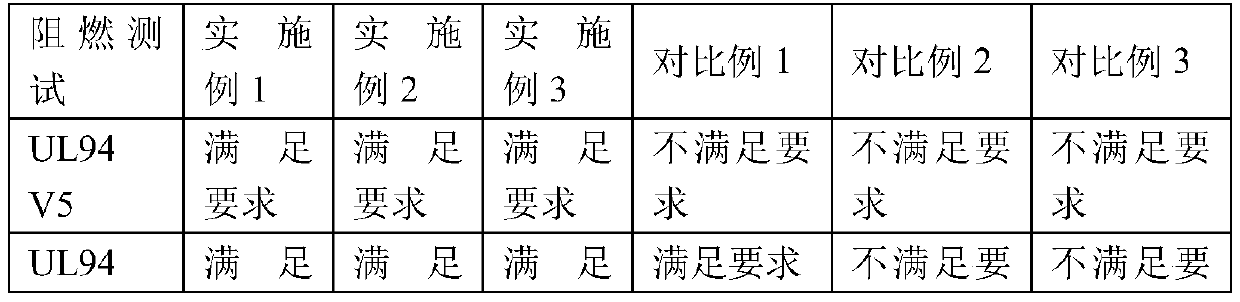

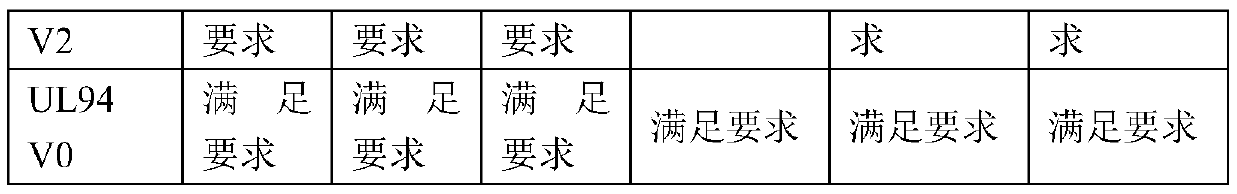

Examples

Embodiment 1

[0029] A production process of high-performance flame-retardant UV paint, comprising the following steps:

[0030] A, take each component according to formula;

[0031] B, the initiator is mixed with deionized water, and the initiator is dissolved to obtain a deionized aqueous solution containing the initiator;

[0032] C. Under the condition of nitrogen protection, add the inorganic flame retardant and organic flame retardant into the deionized aqueous solution containing the initiator, and disperse them homogeneously;

[0033] D. Add water-based UV monomer, active diluent, dispersant, pigment, water-based UV leveling agent and water-based UV defoamer to the deionized aqueous solution containing the initiator, stir and mix to obtain the water-based UV paint.

[0034] Preferably, the high-performance flame-retardant UV paint includes the following components in weight percent:

[0035] Water-based UV monomer 32%

[0036] Initiator 7%

[0037] Reactive diluent 12%

[0038...

Embodiment 2

[0051] A production process of high-performance flame-retardant UV paint, comprising the following steps:

[0052] A, take each component according to formula;

[0053] B, the initiator is mixed with deionized water, and the initiator is dissolved to obtain a deionized aqueous solution containing the initiator;

[0054] C. Under the condition of nitrogen protection, add the inorganic flame retardant and organic flame retardant into the deionized aqueous solution containing the initiator, and disperse them homogeneously;

[0055] D. Add water-based UV monomer, active diluent, dispersant, pigment, water-based UV leveling agent and water-based UV defoamer to the deionized aqueous solution containing the initiator, stir and mix to obtain the water-based UV paint.

[0056] Preferably, the high-performance flame-retardant UV paint includes the following components in weight percent:

[0057] Water-based UV monomer 30%

[0058] Initiator 8%

[0059] Active diluent 8%

[0060] D...

Embodiment 3

[0073] A production process of high-performance flame-retardant UV paint, comprising the following steps:

[0074] A, take each component according to formula;

[0075] B, the initiator is mixed with deionized water, and the initiator is dissolved to obtain a deionized aqueous solution containing the initiator;

[0076] C. Under the condition of nitrogen protection, add the inorganic flame retardant and organic flame retardant into the deionized aqueous solution containing the initiator, and disperse them homogeneously;

[0077] D. Add water-based UV monomer, active diluent, dispersant, pigment, water-based UV leveling agent and water-based UV defoamer to the deionized aqueous solution containing the initiator, stir and mix to obtain the water-based UV paint.

[0078] Preferably, the high-performance flame-retardant UV paint includes the following components in weight percent:

[0079] Water-based UV monomer 40%

[0080] Initiator 2%

[0081] Reactive diluent 15%

[0082...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com