Carbon nanotube modified polyurea explosion-proof material and preparation method thereof

A technology of carbon nanotube modification and explosion-proof materials, which is applied in the direction of polyurea/polyurethane coatings, coatings, etc., to achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

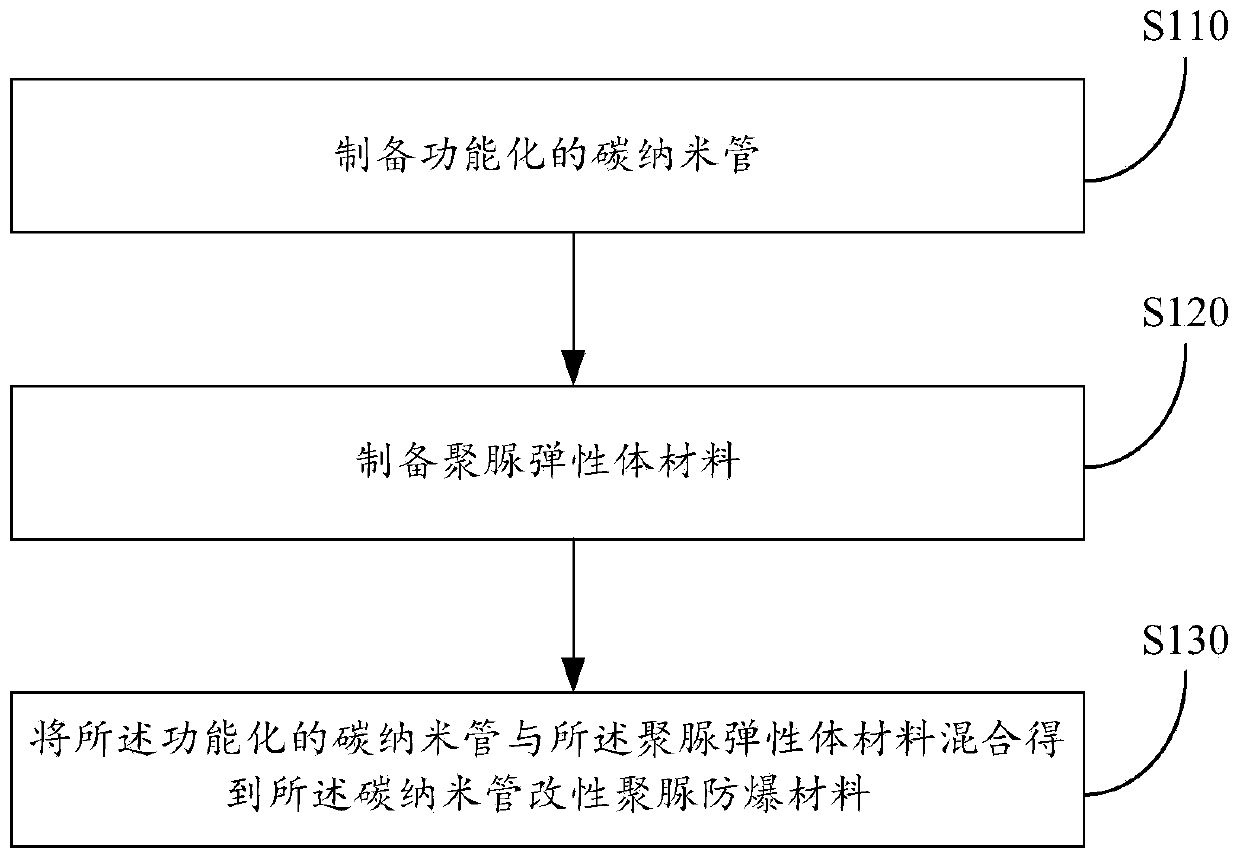

[0032] see figure 1 , a method for preparing a carbon nanotube modified polyurea explosion-proof material provided by the present invention, comprising the following steps:

[0033] Step S110: preparing functionalized carbon nanotubes;

[0034] Step S120: preparing a polyurea elastomer material; and

[0035] Step S130: mixing the functionalized carbon nanotubes with the polyurea elastomer material to obtain the carbon nanotube-modified polyurea explosion-proof material.

[0036] In the carbon nanotube modified polyurea explosion-proof material provided by the present invention, the carbon nanotubes are pre-functionalized, and then the functionalized carbon nanotubes are inserted into the polyurea elastomer resin through a combination of conventional physical dispersion and chemical reaction. , because the whole process does not contain non-reactive pigments and fillers, the physical reinforcement of the filler to the material is abandoned, and at the same time, the defect of...

Embodiment 1

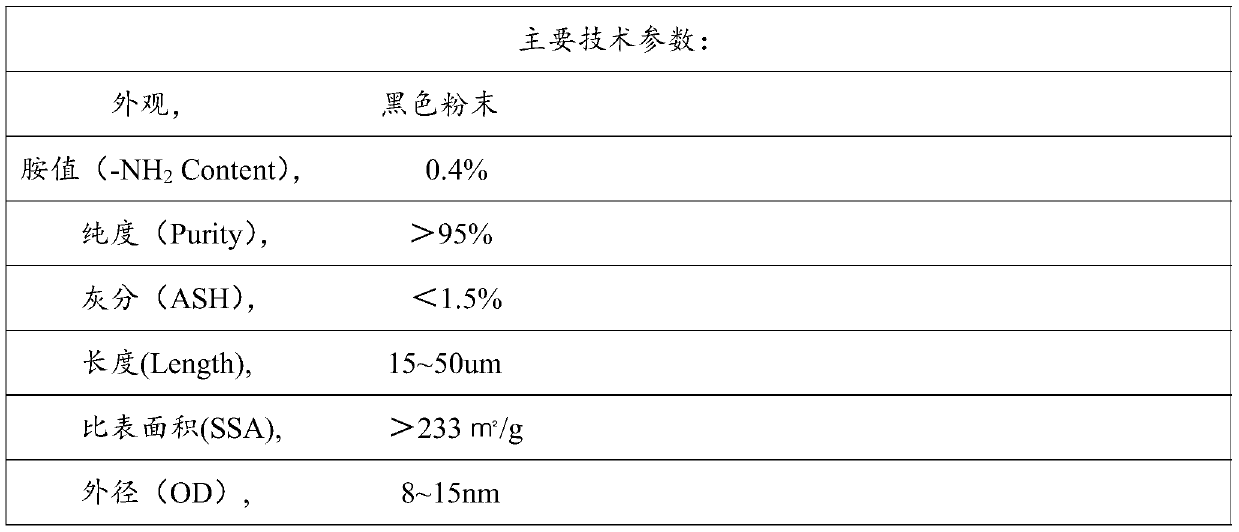

[0063] Preparation of Aminated Carbon Nanotubes

[0064] (1) The multi-walled carbon nanotube raw material is mixed with the mixture of concentrated sulfuric acid and concentrated nitric acid in a weight ratio of 0.1 to 100, treated with 80kHz ultrasonic waves for 48 hours, stirred at 80°C, suction filtered, and washed repeatedly with water until The filtrate is neutral, and after vacuum drying, hydroxyl-functionalized carbon nanotubes are obtained;

[0065] (2) Pre-treat the single-necked flask by evacuating and burning off the water vapor, then fill with nitrogen, add 0.1 parts by weight of the hydroxyl-functionalized carbon nanotubes obtained in step (1) to the processed single-necked flask, and then vacuumize and fill the flask with nitrogen again. 100 parts by weight of dimethylacetamide (DMAC) was added to the mixture and ultrasonic was used for 30 minutes. Then add 1 part by weight of azobisbutylnitrile (AIBN) and 1 part by weight of acrylic acid into the flask, put it...

Embodiment 2

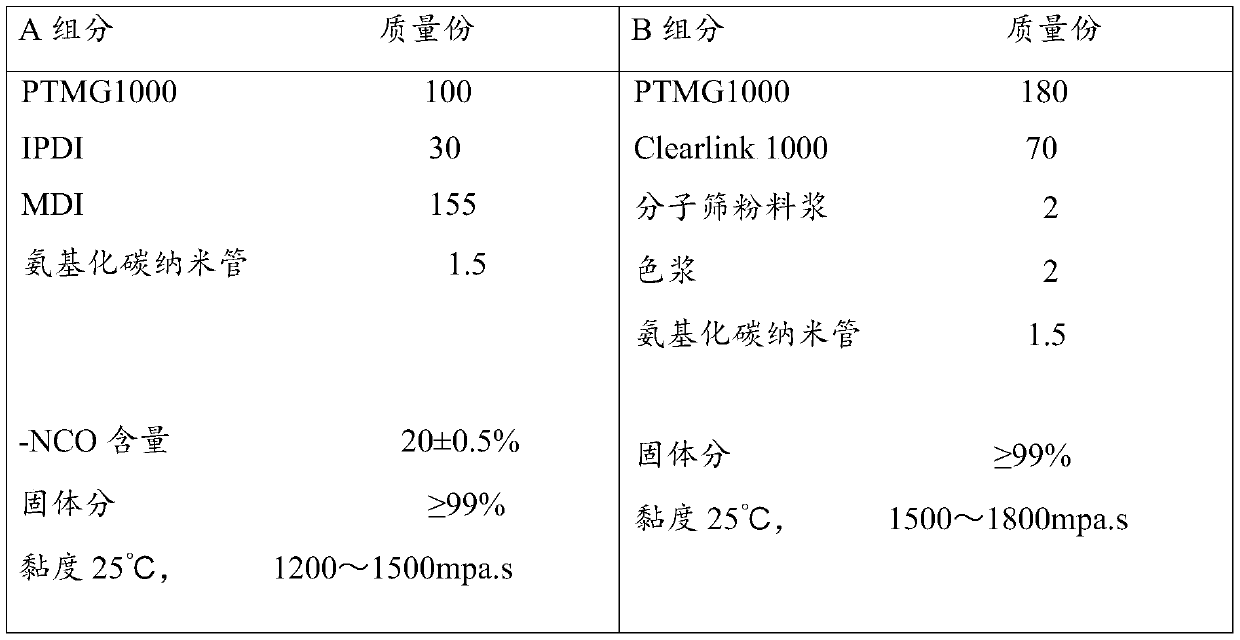

[0070] Preparation of Polyurea Elastomer Material

[0071] The composition and mass parts of A component and B component are as follows:

[0072]

[0073] The volume ratio of component A to component B is 1:1

[0074] The α value (-NCO / -NH) of component A and component B is 1.05~1.10

[0075] The spray paint temperature of component A and component B should be kept at 65℃~70℃

[0076] For the preparation of component A, put PTMG1000 into a reaction kettle with nitrogen protection, heat it to 120°C under stirring, dehydrate it under vacuum -0.1MPa for 2.5 hours, release the vacuum, drop the temperature below 60°C and add polyisocyanate, at 85 React at ℃ for 2 hours. After the reaction is over, measure the NCO value, add functionalized carbon nanotubes, and disperse ultrasonically at 50-60°C for 24 hours. Tube modified isocyanate terminated semi-prepolymer A component.

[0077] For the preparation of component B, weigh each component according to the order of the formula,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com