Low-internal-leakage load-deflection resistance hydraulic cylinder system

An internal leakage, anti-eccentric load technology, applied in the field of hydraulic cylinders, can solve the problems of poor anti-eccentric load effect, can not solve the influence of hydraulic cylinder performance, can not reduce the friction between the piston rod and the cylinder block, etc., to achieve low friction and wear, The effect of reducing internal leakage and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

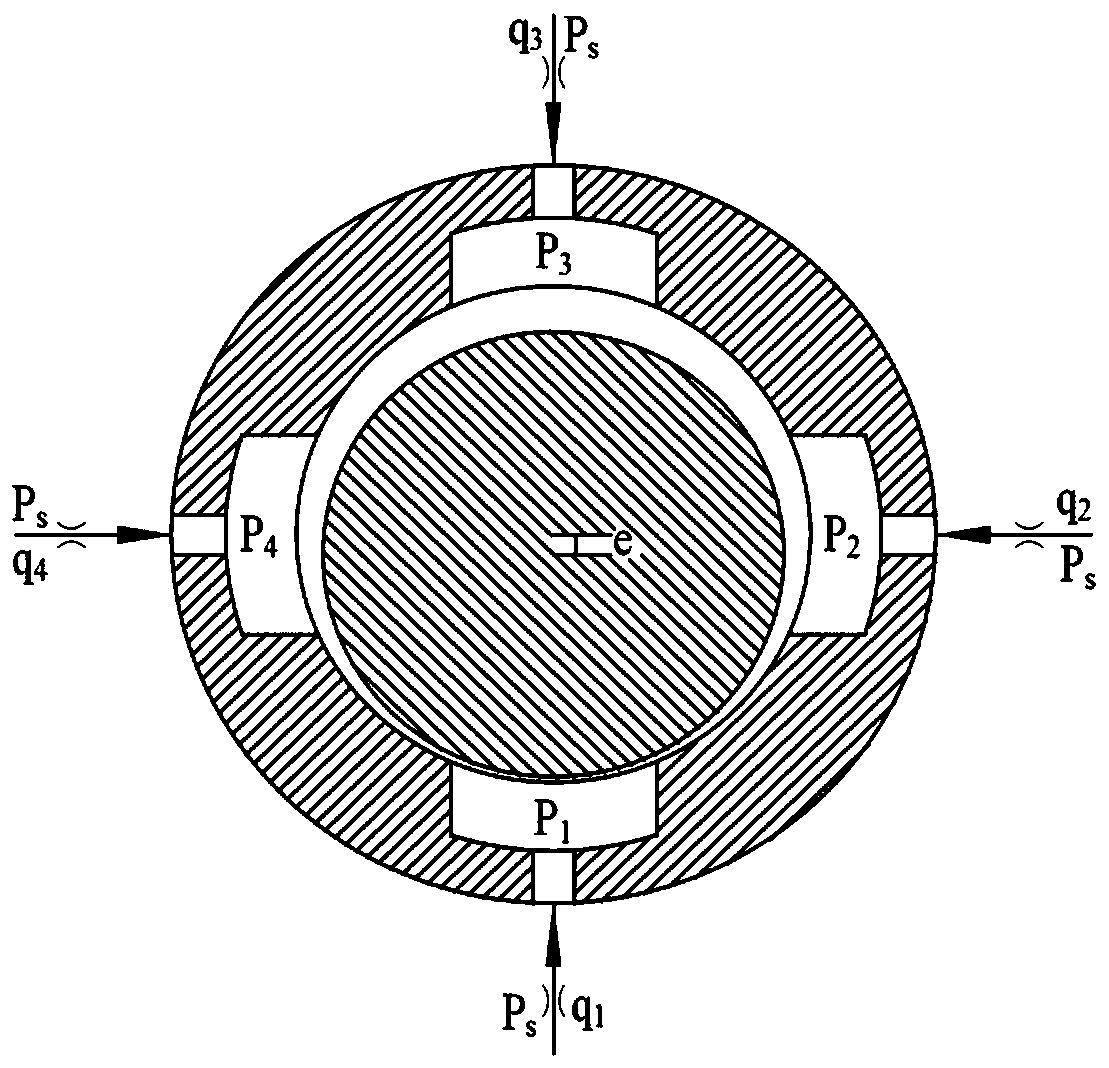

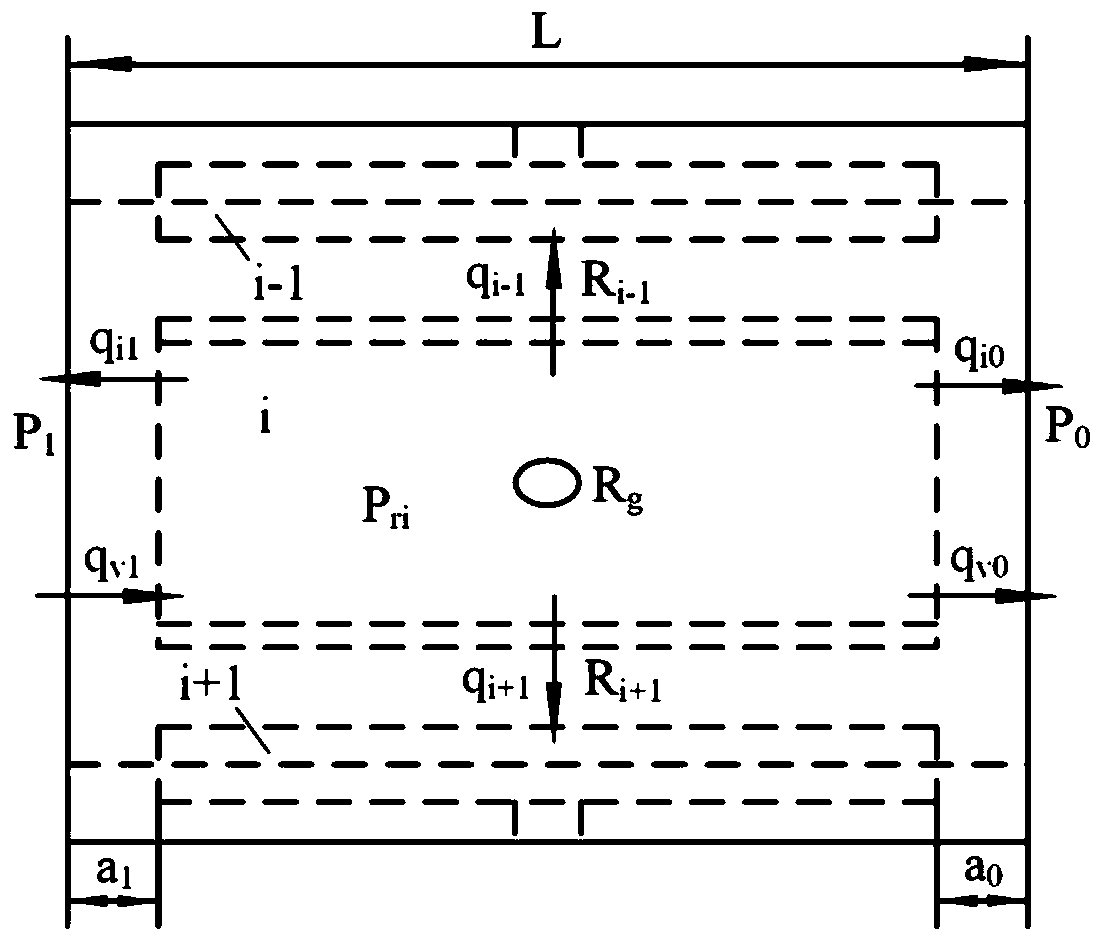

[0036] The invention aims to further improve the anti-eccentric load capacity of the hydraulic cylinder by increasing the forward cone support of the piston on the basis of the existing static pressure support, reduce the friction at the piston, and consider the internal leakage problem between the left and right piston cavities. The invention introduces part of the static pressure support oil into the right piston cavity to supplement the leaked oil through feedback adjustment, thereby effectively reducing internal leakage.

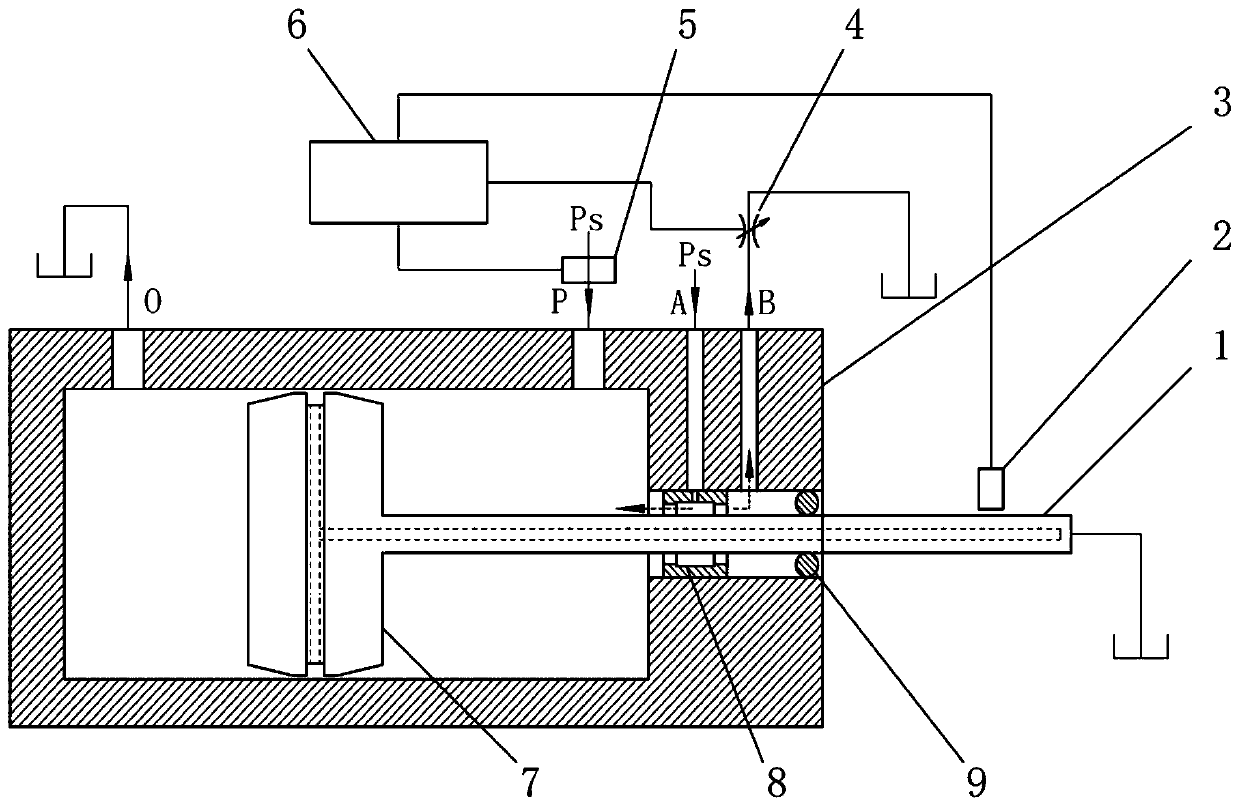

[0037] Such as figure 1 As shown, the present invention provides a low internal leakage anti-offset load hydraulic cylinder system, including a piston rod 1, a speed sensor 2, a hydraulic cylinder body 3, a static pressure support oil return throttle valve 4, a flow sensor 5, and a PID controller 6. Double straight cone piston 7. Static pressure support bearing 8. Seal ring 9. Among them, the signals measured by the speed sensor 2 and the flow sensor 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com