Comprehensive performance testing device of large-torque servo motor driving and loading type reducer

A technology of servo motor and reducer, which is applied in the field of precision reducer test bench, which can solve the problem of not being able to meet the test requirements of multi-specification and multi-size reducer, the structure size of the bench reducer is quite different, and the test device cannot provide load, etc. problem, to achieve the effect of high test efficiency, stable loading range, and many test items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

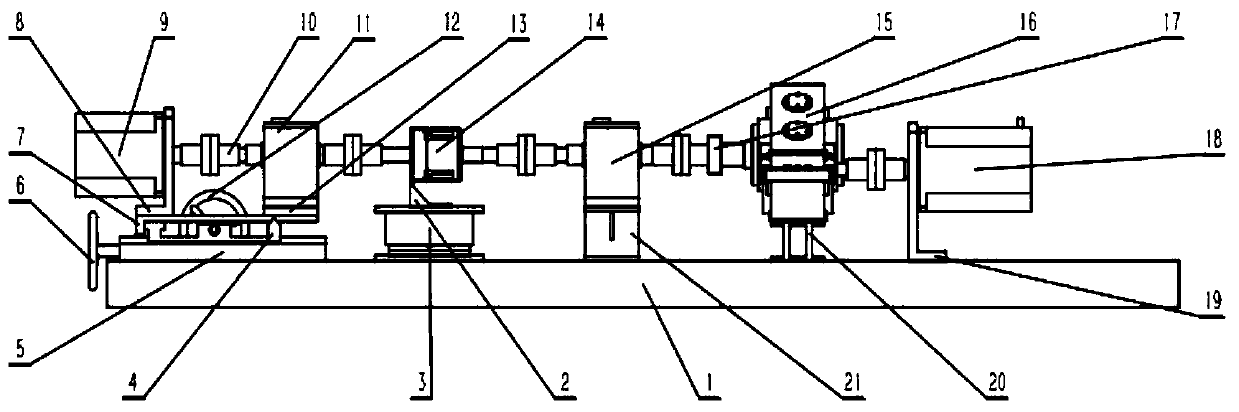

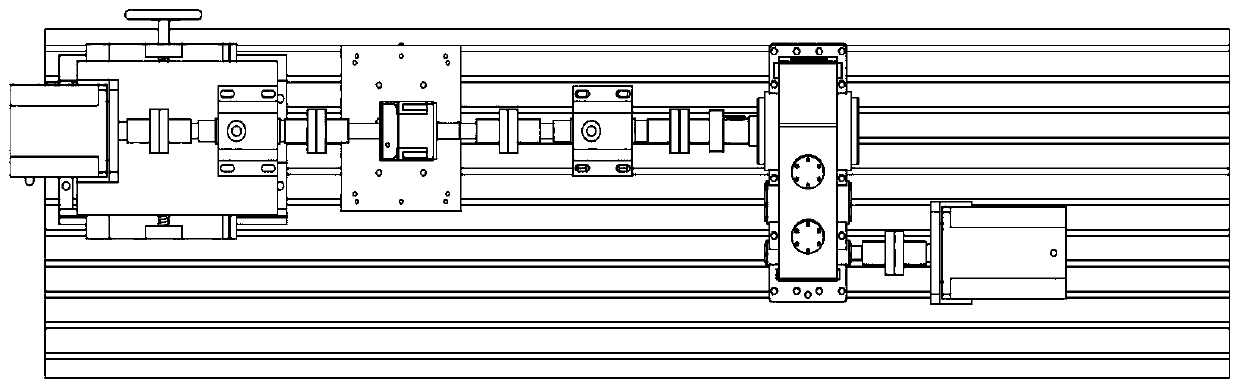

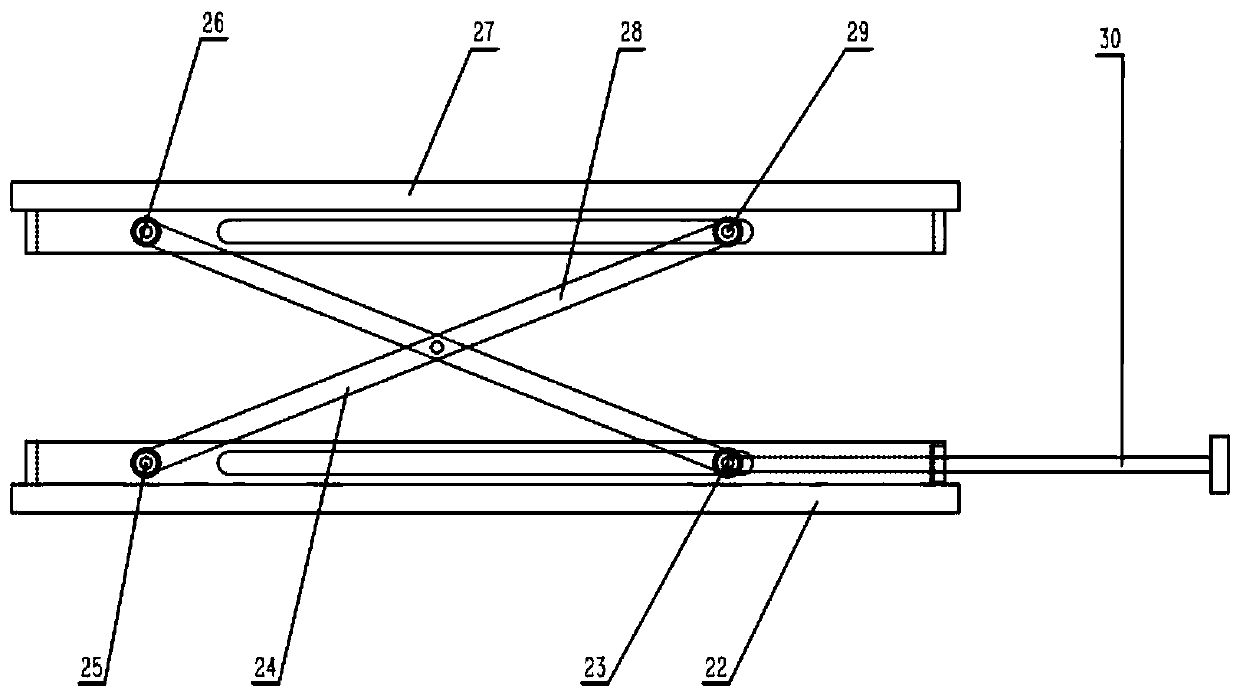

[0016] combine figure 1 , figure 2 , a high-torque servo motor-driven, load-type reducer comprehensive performance testing device, including a motion motor 9, an input torque speed sensor 11, an output torque speed sensor 15, a secondary speed reducer 16, and a loading servo motor 18. The output shaft of the motion motor 9 is connected to one end of the input torque speed sensor 11 through a coupling 10, and the other end of the input torque speed sensor 11 is connected to the input shaft of the speed reducer 14 to be tested through a shaft coupling, and the speed reducer 14 to be tested outputs The shaft is connected to one end of the torque speed sensor 15 at the output end through a coupling, and the other end of the torque speed sensor 15 at the output end is connected to the output shaft of the secondary reducer 16 through a clutch 17, and the input end of the secondary reducer 16 is connected to the output shaft of the secondary reducer 16 through a coupling. 18 output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com