Multi-laser light spot position detecting device and method based on linear array CCD and FPGA

A detection device and detection method technology, applied in the direction of measuring device, radio wave measuring system, measuring distance, etc., to achieve the effect of improving automation, high precision and reducing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

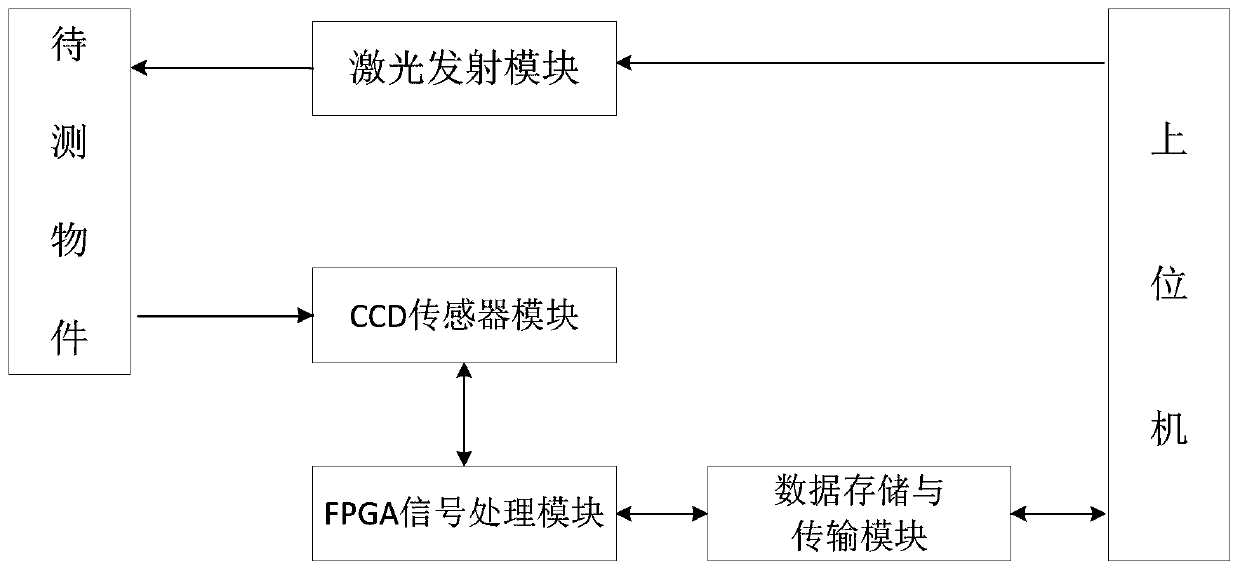

[0023] combine figure 1 , the present invention is based on linear array CCD and FPGA multi-laser spot position detecting device, comprises laser emission module, CCD sensor module, FPGA signal processing module, data storage and transmission module and host computer;

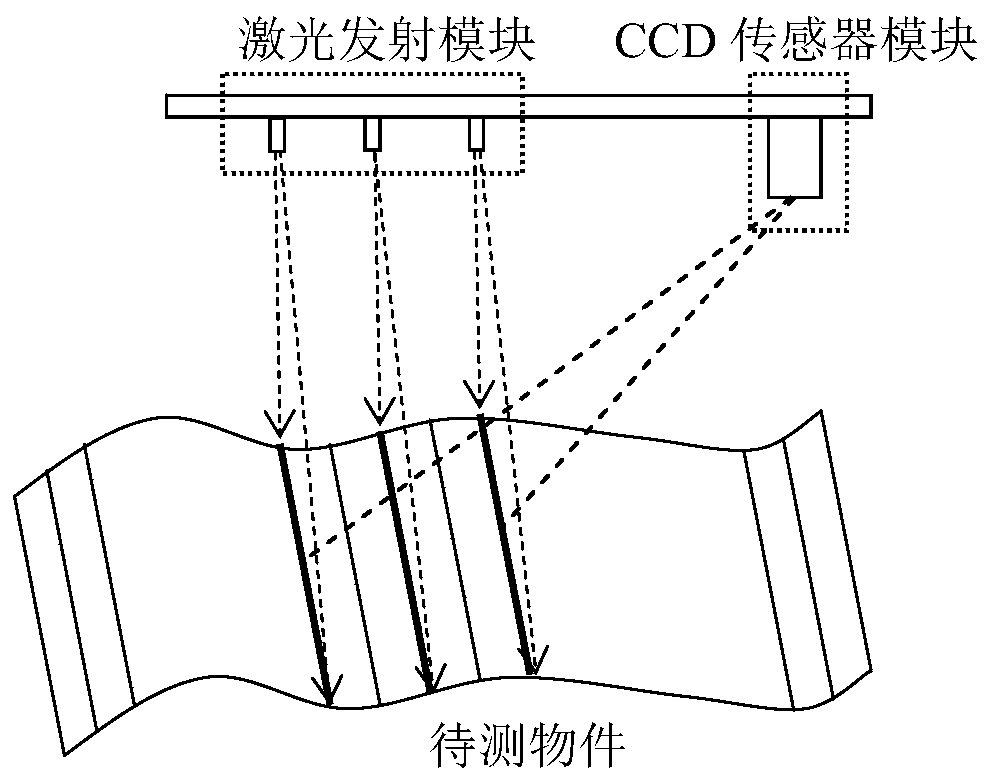

[0024] The laser emitting module is used to vertically emit multi-beam line lasers to the surface of the object to be measured;

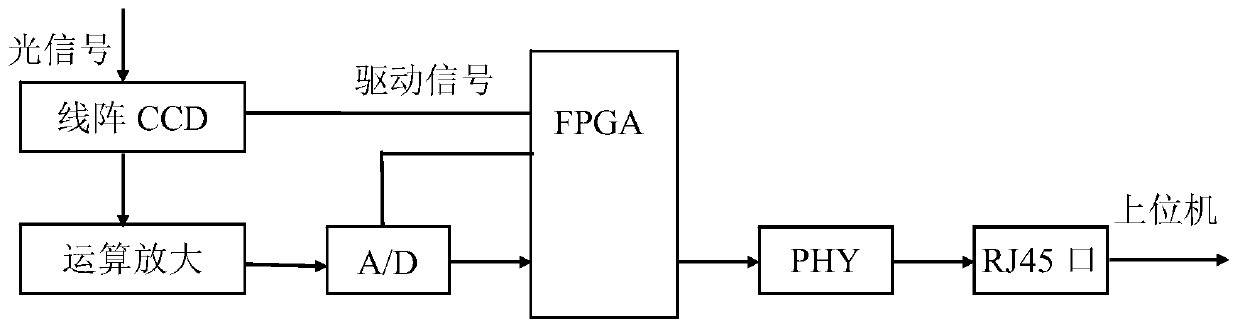

[0025] The CCD sensor module is used to receive the laser light reflected by the object to be measured, and perform photoelectric conversion to complete the collection and conversion of optical signals;

[0026] FPGA signal processing module, used for preprocessing and analog-to-digital conversion of analog electrical signals after photoelectric conversion, and realizing multi-laser spot center positioning;

[0027] The data storage and transmission module is used to store the image data of the FPGA signal processing module, and transmit the center positioning results of multiple la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com