Electrical insulation sealing structure of oil-cooled permanent magnet motor and assembly method

A technology of permanent magnet motor and sealing structure, which is applied in the direction of electromechanical devices, winding insulation shape/style/structure, manufacturing motor generators, etc., and can solve problems such as bulky, insufficient cooling of the stator, and complex motor casings. Achieve the effect of small size, good stator cooling effect and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

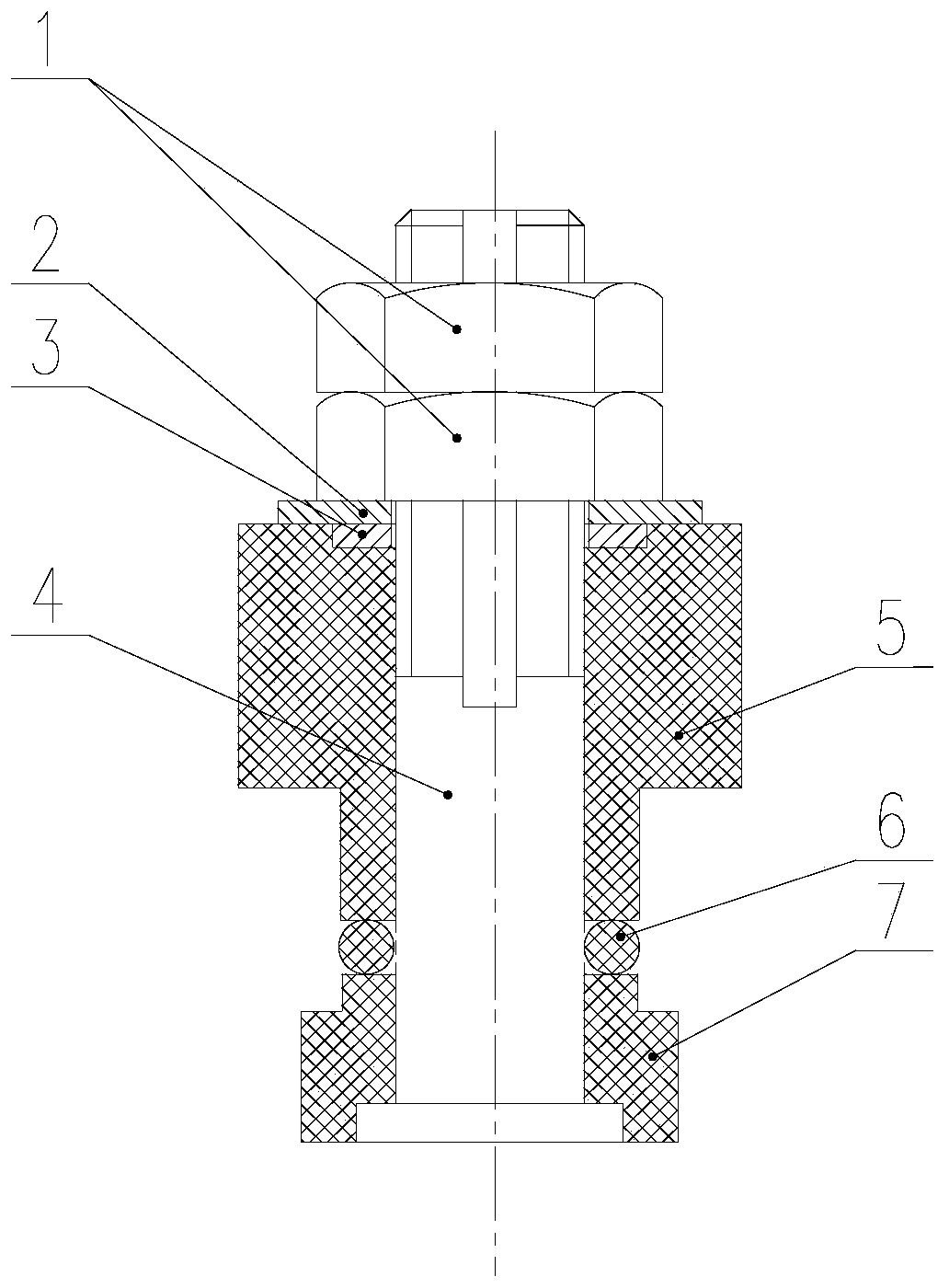

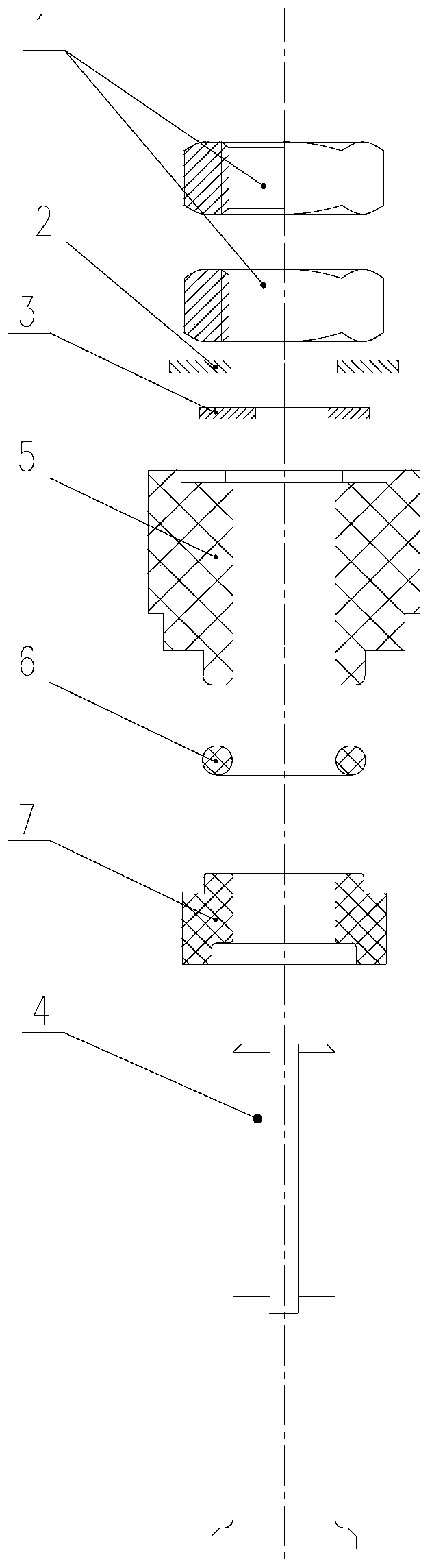

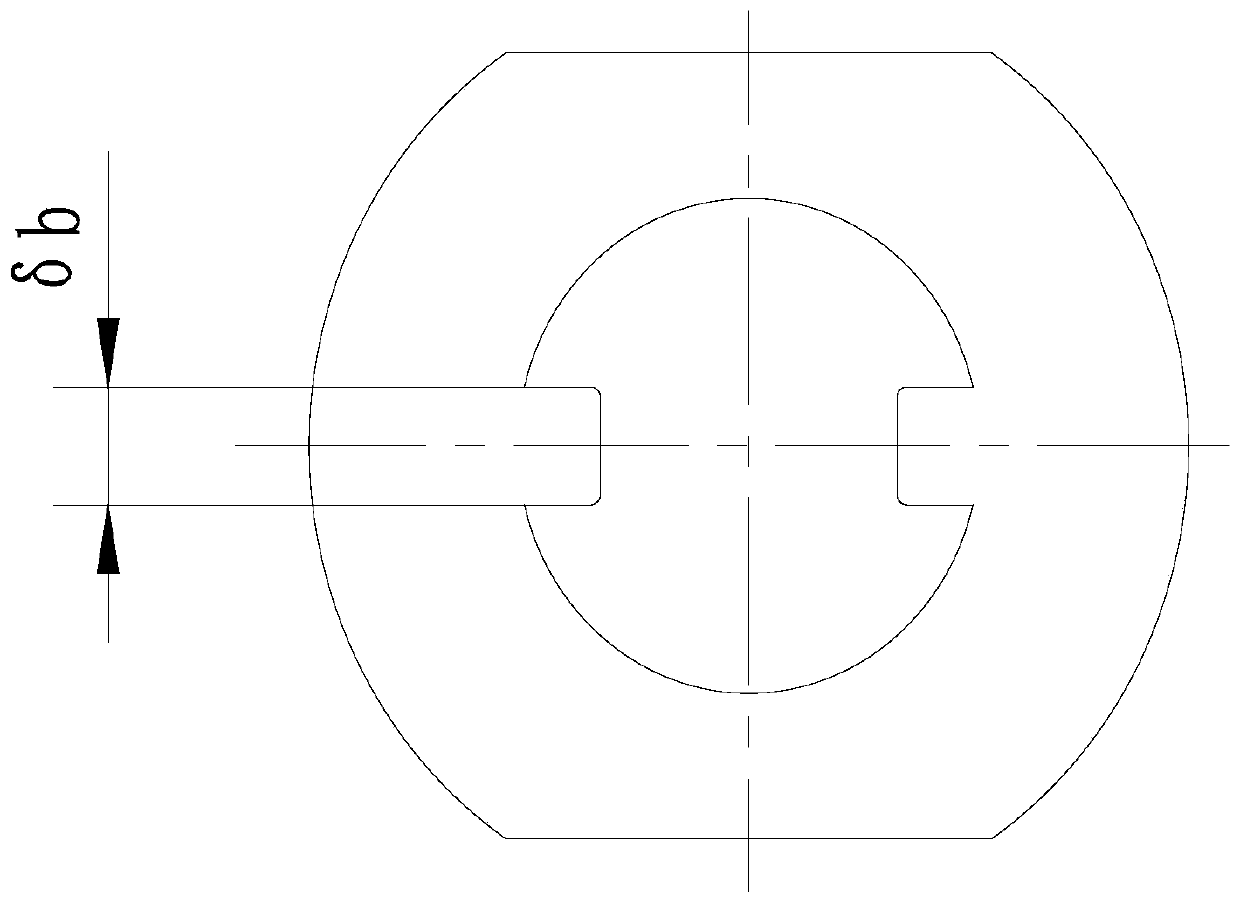

[0019] The electric insulation and sealing structure of the oil-cooled permanent magnet motor ( figure 1 ) consists of compression nut 1 (two), metal flat washer 2, positioning backing plate 3, lead terminal with groove 4, positioning insulator 5, O-ring rubber ring 6, and inner insulator 7. The compression nuts 1 (two) and metal flat washers 2 are made of copper material with good electrical conductivity, and are used to effectively fix the electrical insulation and sealing structure components of the oil-cooled permanent magnet motor on the motor On the housing, the positioning backing plate 3 ( figure 2 ) is a symmetrical trimming circle, which is used for the circumferential positioning of the positioning backing plate 3 and the positioning insulator 5; the inner hole of the positioning backing plate 3 has two teeth with a width of δb, and the two teeth Cooperate with the two grooves of the lead terminal 4 with the groove, and prevent the lead terminal 4 with the groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com