A kind of repair method of motor commutator

A motor commutator and repair method technology, which is applied in the field of aviation equipment, can solve the problems of increasing repair cost and restricting repair cycle, commutator wear diameter becomes smaller, and the finished product of the motor is scrapped, so as to achieve low repair cost and short repair cycle , The effect of simple repair method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

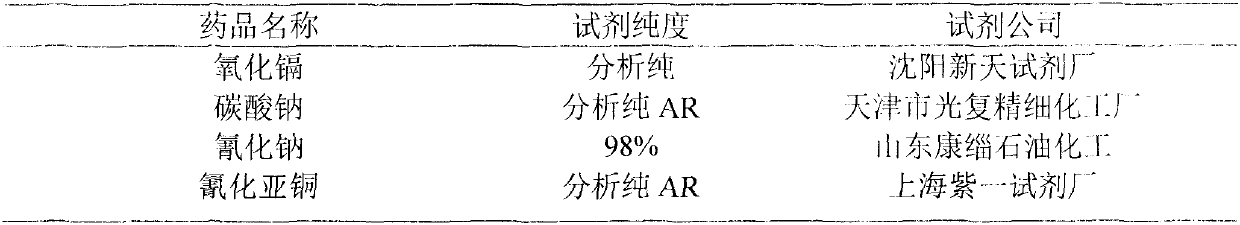

Method used

Image

Examples

Embodiment 1

[0036] A method for repairing a motor commutator, the specific steps of the method are as follows:

[0037] (1) car repair

[0038] Grind the worn part of the commutator of the motor commutator to make its surface smooth; then cut the unworn part of the commutator, and the cutting depth is the wear thickness; finally, polish the surface of the motor commutator;

[0039] (2) cleaning

[0040] Cover the surface of the commutator after car repair with a film to expose the commutator piece; then put the commutator into a mixed solution of sodium hydroxide, sodium phosphate and sodium silicate (the concentration of sodium hydroxide is 5g / L , the concentration of sodium phosphate is 20g / L, the concentration of sodium silicate is 3g / L), soak at 80°C for 15min; take the commutator out of the cleaning solution, rinse it with 40°C flowing warm water, and then Rinse in running cold water below 38°C until a layer of water film is formed on the surface of the commutator, the water film n...

Embodiment 2

[0053] A method for repairing a motor commutator, the specific steps of the method are as follows:

[0054] (1) car repair

[0055] Grind the worn part of the commutator of the motor commutator to make its surface smooth; then cut the unworn part of the commutator, and the cutting depth is the wear thickness; finally, polish the surface of the motor commutator;

[0056] (2) cleaning

[0057] Cover the surface of the commutator after car repair with a film to expose the commutator piece; then put the commutator into a mixed solution of sodium hydroxide, sodium phosphate and sodium silicate (the concentration of sodium hydroxide is 15g / L , the concentration of sodium phosphate is 25g / L, the concentration of sodium silicate is 15g / L), soak at 60°C for 20min; take the commutator out of the cleaning solution, rinse it with flowing warm water at 60°C, and then Rinse in running cold water below 38°C until a layer of water film is formed on the surface of the commutator, the water f...

Embodiment 3

[0070] A method for repairing a motor commutator, the specific steps of the method are as follows:

[0071] (1) car repair

[0072] Grind the worn part of the commutator of the motor commutator to make its surface smooth; then cut the unworn part of the commutator, and the cutting depth is the wear thickness; finally, polish the surface of the motor commutator;

[0073] (2) cleaning

[0074] Cover the surface of the commutator after the car repair with a film to expose the commutator piece; then put the commutator into a mixed solution of sodium hydroxide, sodium phosphate and sodium silicate (the concentration of sodium hydroxide is 10g / L , the concentration of sodium phosphate is 23g / L, the concentration of sodium silicate is 4g / L), soak at 70°C for 18min; take the commutator out of the cleaning solution, rinse it with flowing warm water at 50°C, and then Rinse in running cold water below 38°C until a water film is formed on the surface of the commutator, the water film ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com