Camping house repairing method

A camping house and cleaning treatment technology, which is applied in the field of camping house repair, can solve the problems of water seepage in the wall, damage to the interior, and affect the quality and service life of the camping house, so as to achieve repair leakage, high repair cost performance and good repair effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for repairing a camping house, comprising the steps of:

[0034] (1) Cleaning treatment:

[0035] Clean the base layer of the camping house to be repaired first, and reserve it after completion;

[0036] (2) Paint coating treatment:

[0037] Apply the pre-prepared repair paint to the base of the cleaned camping house to be repaired;

[0038] (3) Ultrasonic treatment:

[0039] Ultrasonic treatment of the applied coating;

[0040] (4) Drying treatment:

[0041] Naturally dry the treated paint until the paint is completely dry.

[0042] The cleaning process in step (1) is to firstly polish with sandpaper, then rinse and clean with clean water, and finally dry it with cotton cloth.

[0043] Coating in step (2) is to be made by the material of following corresponding weight part:

[0044] 4 parts of propylene glycol methyl ether acetate, 2 parts of polyacetate latex, 1 part of silica sol, 2 parts of dispersant, 0.1 part of defoamer, 3 parts of ethylene glycol...

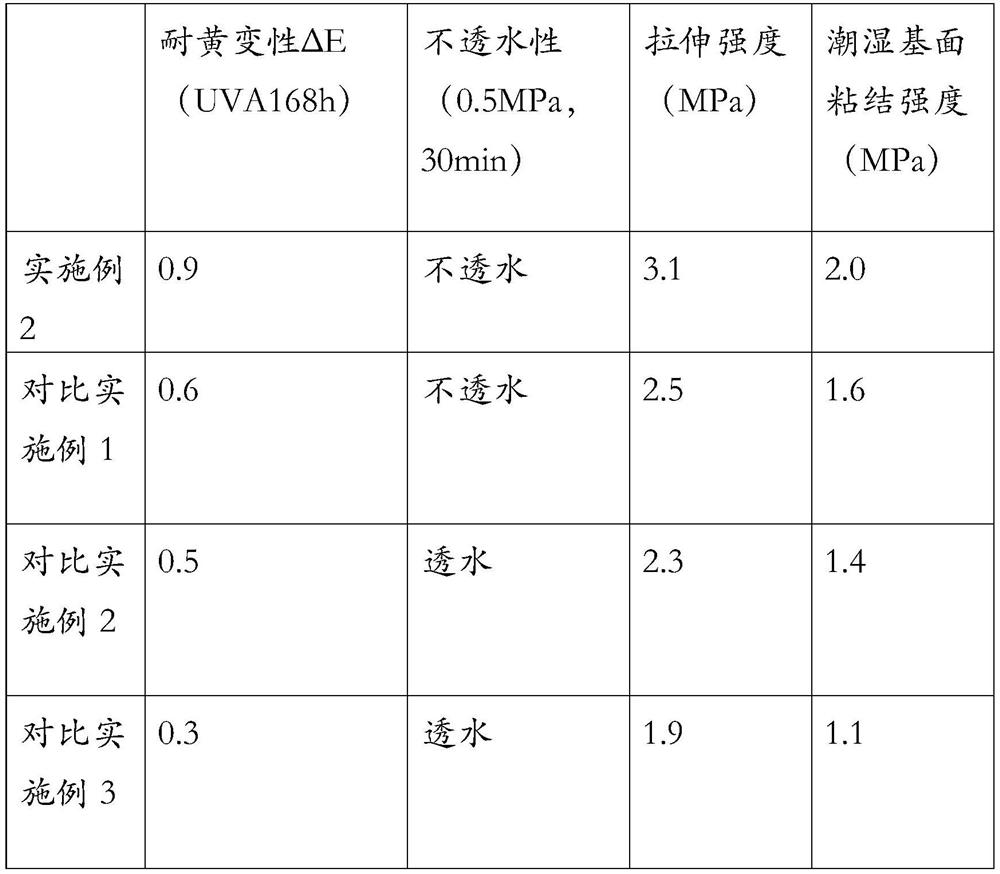

Embodiment 2

[0055] A method for repairing a camping house, comprising the steps of:

[0056] (1) Cleaning treatment:

[0057] Clean the base layer of the camping house to be repaired first, and reserve it after completion;

[0058] (2) Paint coating treatment:

[0059] Apply the pre-prepared repair paint to the base of the cleaned camping house to be repaired;

[0060] (3) Ultrasonic treatment:

[0061] Ultrasonic treatment of the applied coating;

[0062] (4) Drying treatment:

[0063] Naturally dry the treated paint until the paint is completely dry.

[0064] The cleaning treatment in the step (1) is to firstly perform a grinding treatment, then wash it with clean water, and finally dry it.

[0065] The cleaning process in step (1) is to firstly polish with sandpaper, then rinse and clean with clean water, and finally dry it with cotton cloth.

[0066] Coating in step (2) is to be made by the material of following corresponding weight part:

[0067] 6 parts of propylene glycol m...

Embodiment 3

[0078] A method for repairing a camping house, comprising the steps of:

[0079] (1) Cleaning treatment:

[0080] Clean the base layer of the camping house to be repaired first, and reserve it after completion;

[0081] (2) Paint coating treatment:

[0082] Apply the pre-prepared repair paint to the base of the cleaned camping house to be repaired;

[0083] (3) Ultrasonic treatment:

[0084] Ultrasonic treatment of the applied coating;

[0085] (4) Drying treatment:

[0086] Naturally dry the treated paint until the paint is completely dry.

[0087] The cleaning treatment in the step (1) is to firstly perform a grinding treatment, then wash it with clean water, and finally dry it.

[0088] The cleaning process in step (1) is to firstly polish with sandpaper, then rinse and clean with clean water, and finally dry it with cotton cloth.

[0089] Coating in step (2) is to be made by the material of following corresponding weight part:

[0090] 8 parts of propylene glycol m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com