Eyebrow pencil and manufacturing method thereof

An eyebrow pencil and a technology of parts by weight, applied in the field of eyebrow pencil and its production, can solve problems such as damage to skin health, pigmentation, uneven quality, etc., and achieve the effect of convenient makeup removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

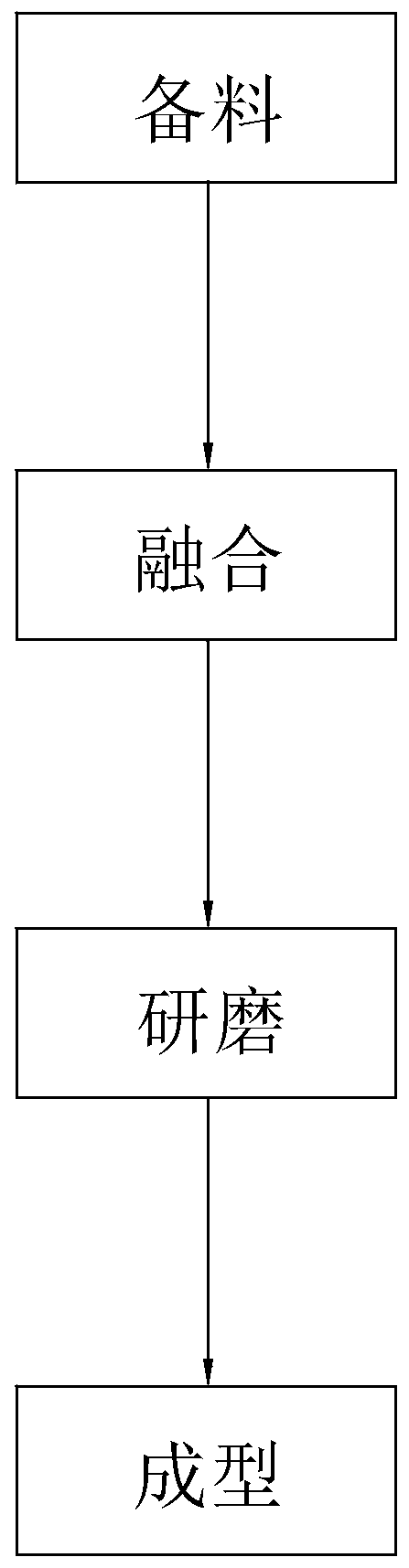

[0063] Embodiment 1: A kind of eyebrow pencil, each component and its corresponding parts by weight are as shown in Table 1, and are prepared through the following steps:

[0064] Step 1, material preparation: Weigh each component respectively, then pulverize the synthetic Japanese wax, filler and colorant in the component and pass through a 1200 mesh sieve for subsequent use;

[0065]Step 2, fusion: put the synthetic Japanese wax into the melting pot, stir and raise the temperature to 90°C to melt the synthetic Japanese wax, then add stearic acid, emollient, tocopherol, ginger extract, ginseng extract, ganoderma lucidum Extract, rosemary extract, stir and mix evenly, stop heating, cool down to 60°C, add filler and coloring agent, stir evenly;

[0066] Step 3, Grinding: Put the mixed material in Step 2 into the grinder, and grind it 3 times until the material body is completely dispersed and even;

[0067] Step 4, Forming: After standing at a constant temperature of 25°C for ...

Embodiment 2-6

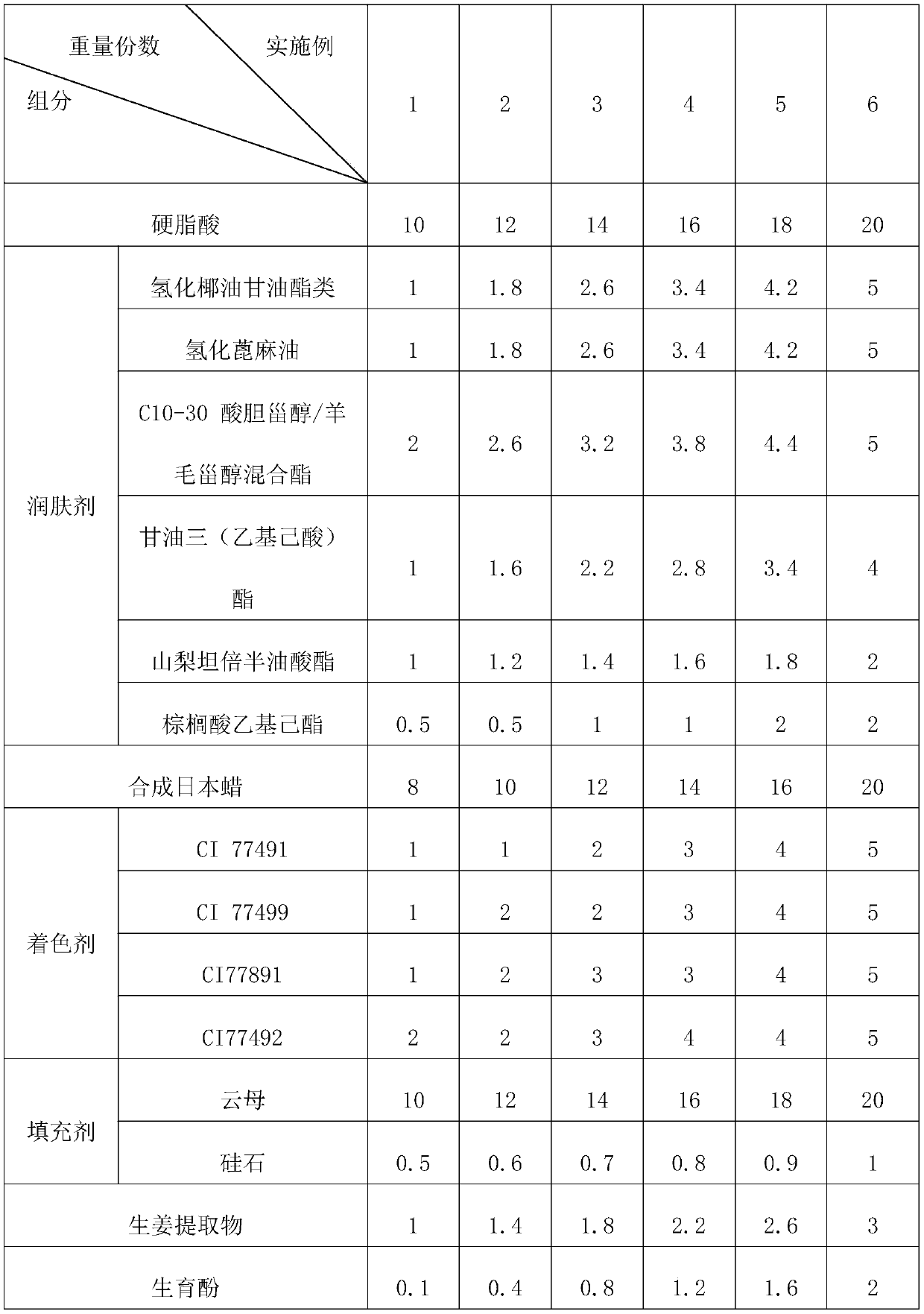

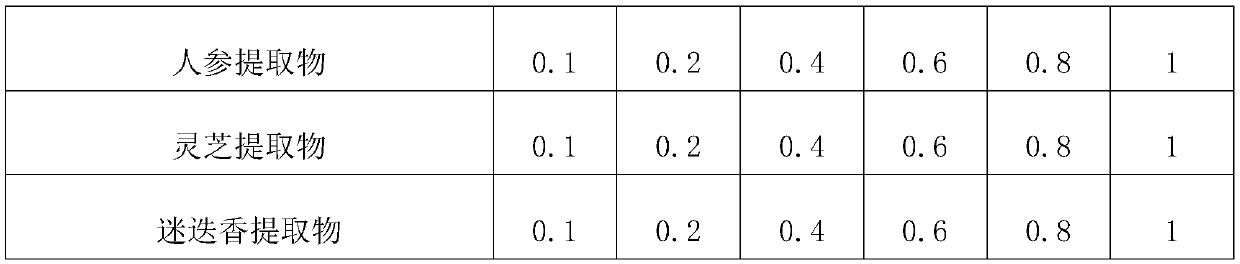

[0068] Embodiment 2-6: An eyebrow pencil, the difference from Embodiment 1 is that each component and its corresponding parts by weight are as shown in Table 1.

[0069] Each component and parts by weight thereof in table 1 embodiment 1-6

[0070]

[0071]

Embodiment 7

[0072] Embodiment 7: a kind of eyebrow pencil, is prepared through the following steps:

[0073] Step 1, material preparation: in parts by weight, 8 parts of synthetic Japanese wax, 5 parts of colorant, and 10.5 parts of filler are pulverized and passed through a 1200-mesh sieve for subsequent use;

[0074] Step 2, fusion: Put the synthetic Japanese wax into the melting pot, stir and heat up to 90°C to melt the synthetic Japanese wax, then add 10 parts of stearic acid, 1 part of hydrogenated cocoglycerides, and 1 part of hydrogenated castor oil , 2 parts C10-30 acid cholesterol / lanosterol mixed ester, 1 part triglyceride (ethylhexanoate), 1 part sorbitan sesquioleate, 0.1 part tocopherol, 1 part ginger extract, 0.1 part Ginseng extract, 0.1 part of ganoderma lucidum extract, 0.1 part of rosemary extract, 0.1 part of PEG glyceryl ether isomeric fatty acid ester, stir and mix well, stop heating, cool down to 60°C, add filler and colorant, stir well ;

[0075] Step 3, Grinding:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com