Tray-free variable-diameter multi-connecting rod winding system

A pallet-less, multi-link technology, applied in the manufacture of inductors/transformers/magnets, electrical components, and the delivery of filamentous materials, can solve problems such as unsatisfactory requirements and troublesome fine-tuning, so as to prevent instability and improve compactness , to facilitate the effect of limiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

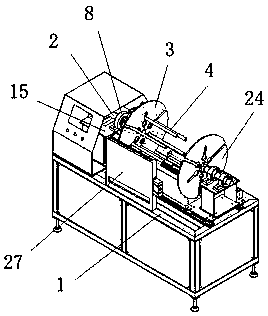

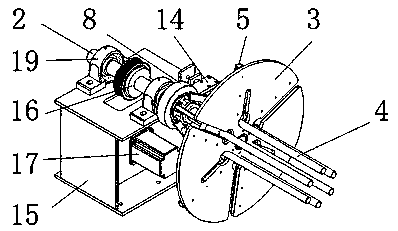

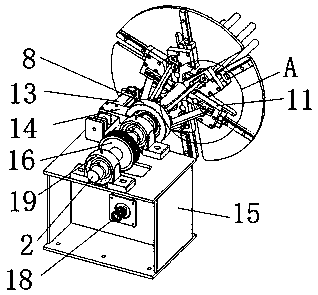

[0058] refer to Figure 1-9 , palletless variable-diameter multi-link winding equipment, including machine 1, drive assembly and winding assembly; the drive assembly and winding assembly are both located on machine 1, and the winding assembly is connected to the drive assembly; winding The assembly is provided with a winding main shaft 2, a winding baffle 3 and at least two reducing assemblies; the driving assembly includes an equipment box 15 arranged on the upper surface of the machine table 1 and a large synchronous pulley 16 sleeved on the surface of the winding main shaft 2, The inside of equipment case 15 is provided with drive motor 17, and the output shaft of drive motor 17 is fixedly connected with small synchronous pulley 18, and small synchronous pulley 18 is connected with large synchronous pulley 16 by belt transmission; The upper surface of equipment case 15 is fixedly connected There is a first bearing seat 19 for fixing the winding main shaft. The upper surface...

Embodiment 2

[0062] refer to Figure 8-12 , different from Embodiment 1, the edge of the middle section of the machine table 1 is also provided with a wire feeding tension mechanism that is kept parallel to the winding roller 4 and used to adjust the tension of the wire feeding. 1 The tension frame 27 on the upper surface, the side of the tension frame 27 away from the winding roller 4 is provided with a wire inlet hole 28, and the side of the tension frame 27 close to the winding roller 4 is provided with a wire outlet hole 29, the wire inlet hole 28 and the wire outlet hole The inwall of 29 is all rotatably connected with rolling bar 30, and the inside of tension frame 27 is provided with chute 31, and the side of tension frame 27 is fixedly connected with drive motor 32, is slidably connected with slide block 33 in the chute 31, and the side of slide block 33 Fixedly connected with the limit block 34, the output shaft of the driving motor 32 runs through the side of the tension frame 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com