Secondary biochemical treatment technology based on SBR method

A treatment process, secondary biochemical technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, aerobic process treatment, etc., can solve the problem that activated sludge cannot be reused, aeration pipes are easily blocked, and energy consumption is high. problems, to achieve the effect of convenient combined use of sewage treatment, streamlining the number of equipment, and high oxygenation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

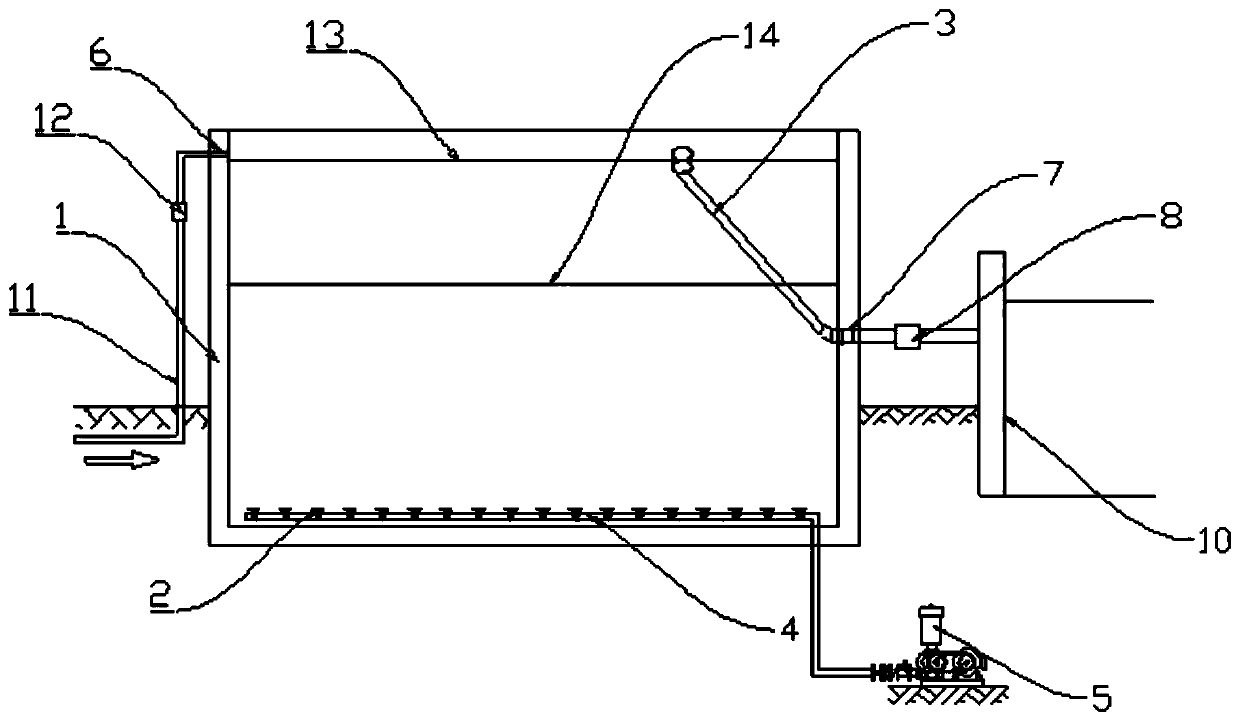

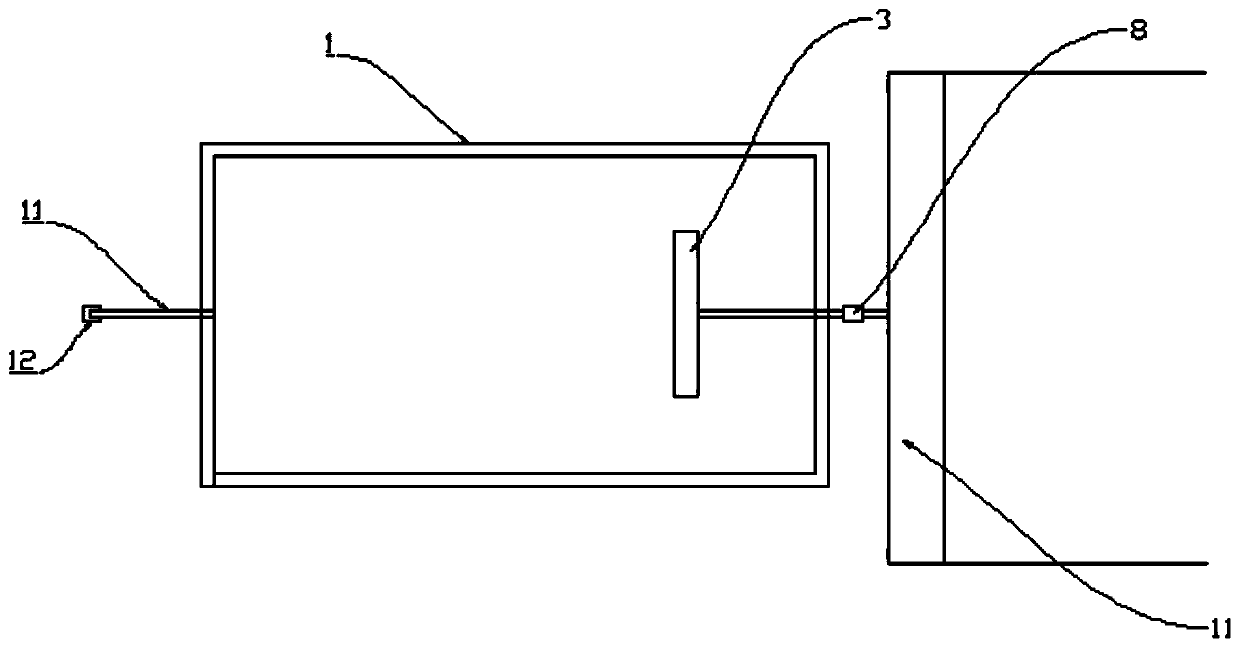

[0026] A secondary biochemical treatment process based on the SBR method, including water intake, aeration, sedimentation, drainage and idle stages, all stages occur inside the SBR tank 1; the inside of the SBR tank 1 is equipped with an aerator 2 and a decanter The control switches of the water tank 3, the aerator 2 and the decanter 3 are all connected to the control device arranged outside the SBR pool 1 through electrical signals, and at the same time, in order to be more conveniently connected to the constructed wetland 10, the SBR pool 1 in this example is half Buried in the ground, the upper left part of the SBR pool 1 is provided with a water inlet 6, and the water inlet 6 is connected to the water inlet pipe 11 arranged on the left side of the SBR pool 1, and the water inlet pipe 11 in this example is provided with an electromagnetic valve 12 , The electromagnetic valve 12 is also connected with the control device through an electric signal. The middle part of the righ...

Embodiment 2

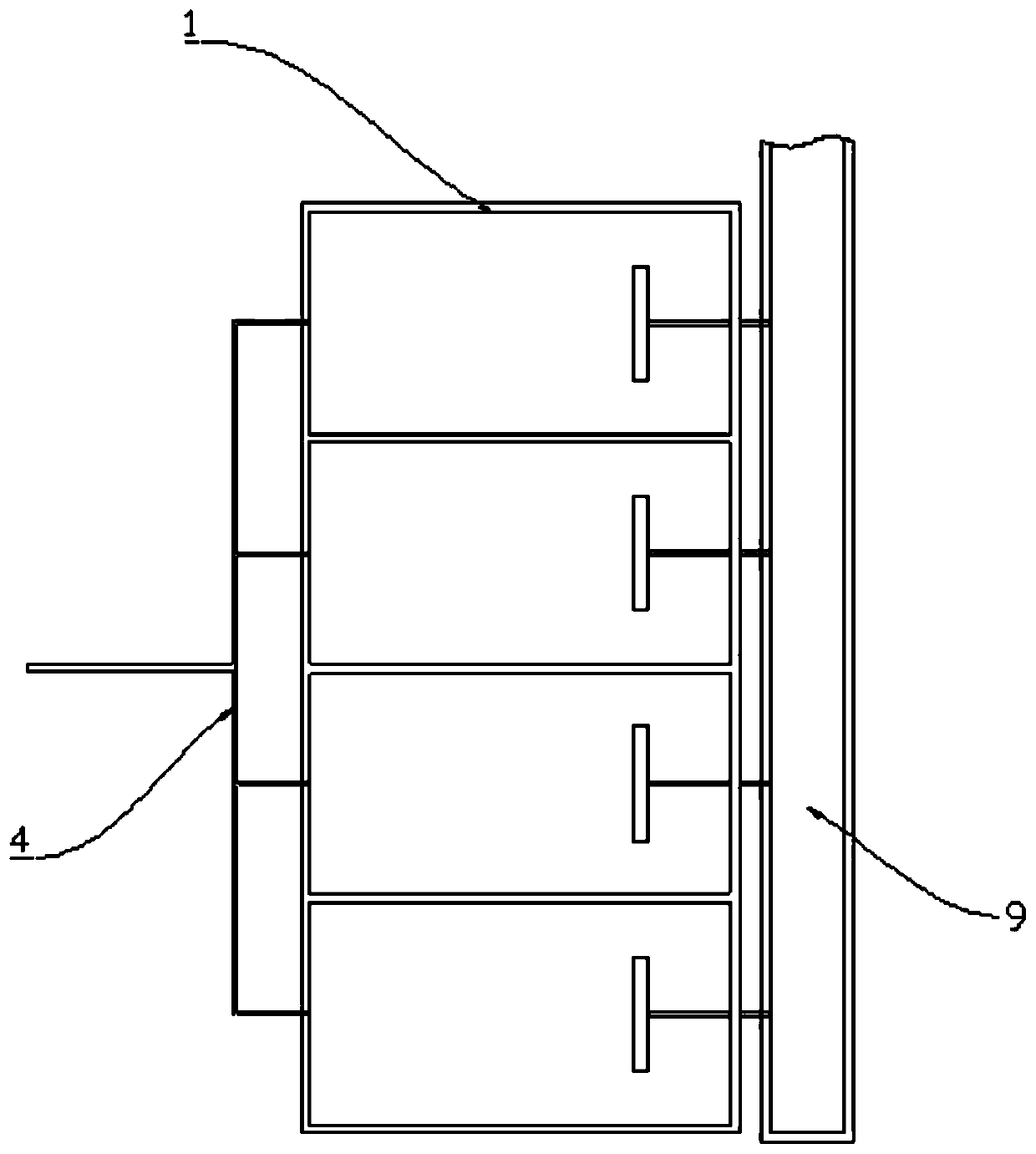

[0029] A secondary biochemical treatment process based on the SBR method, including four SBR pools 1 arranged side by side. The interior of each SBR pool 1 includes water intake, aeration, sedimentation, drainage and idle stages. The interior of the four SBR pools 1 The structure is the same as that in Example 1, and each control switch inside the four SBR pools 1 is connected to the same control device; the water inlets 6 of the four SBR pools 1 are all connected to the same water inlet pipeline 11 in this example , the water outlets 7 of the four SBR pools 1 are all connected to a drainage channel 9 extending horizontally in the front and rear directions. The number of water outlet pipes connected to the water outlet 7 can reduce the probability of the water outlet 7 of the SBR pool 1 being blocked due to the blockage of the water outlet pipes while saving the material of the water outlet pipes. Four SBR pools 1 are arranged in sequence from front to back. After the water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com