A textile rapid drying device capable of deflocculation

A rapid drying and weaving technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of fabrics that cannot be processed, and achieve the effects of accelerating drying speed, expanding surface area, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

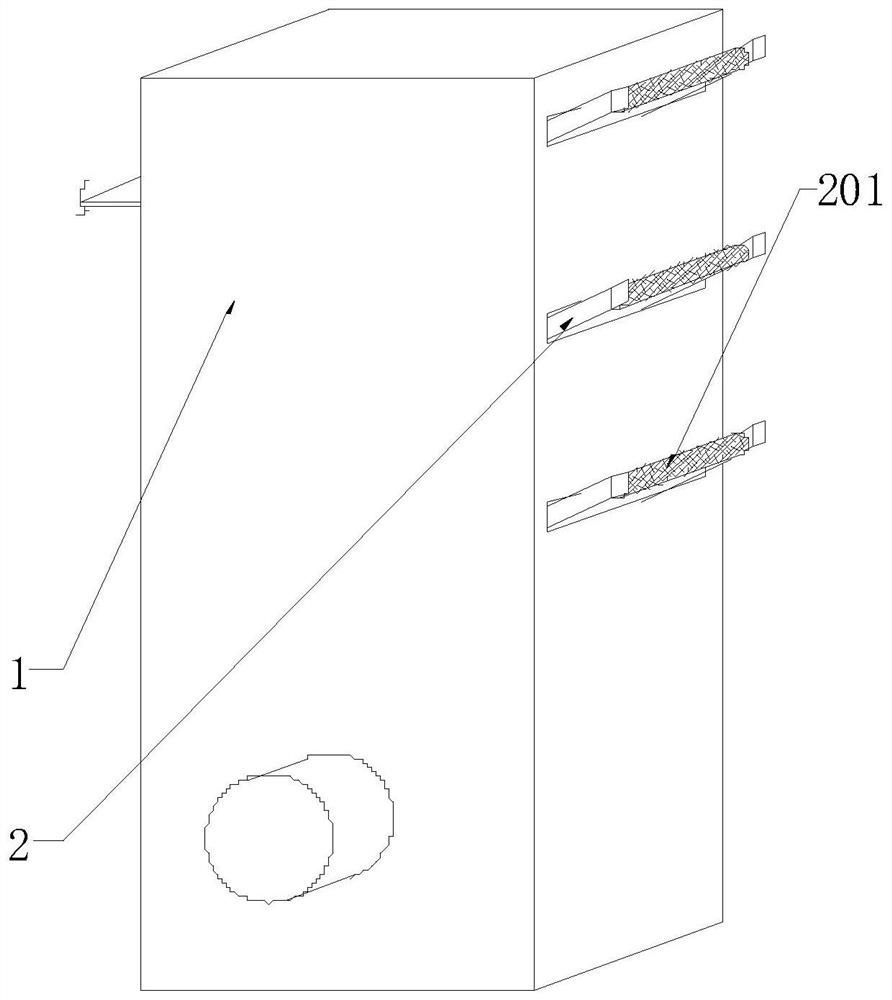

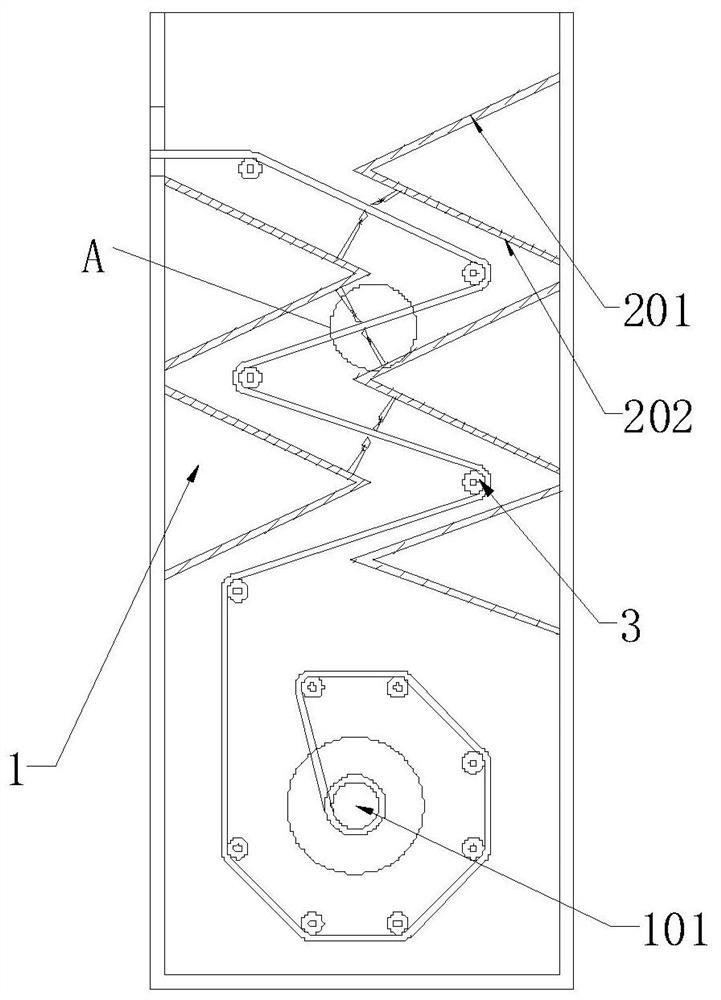

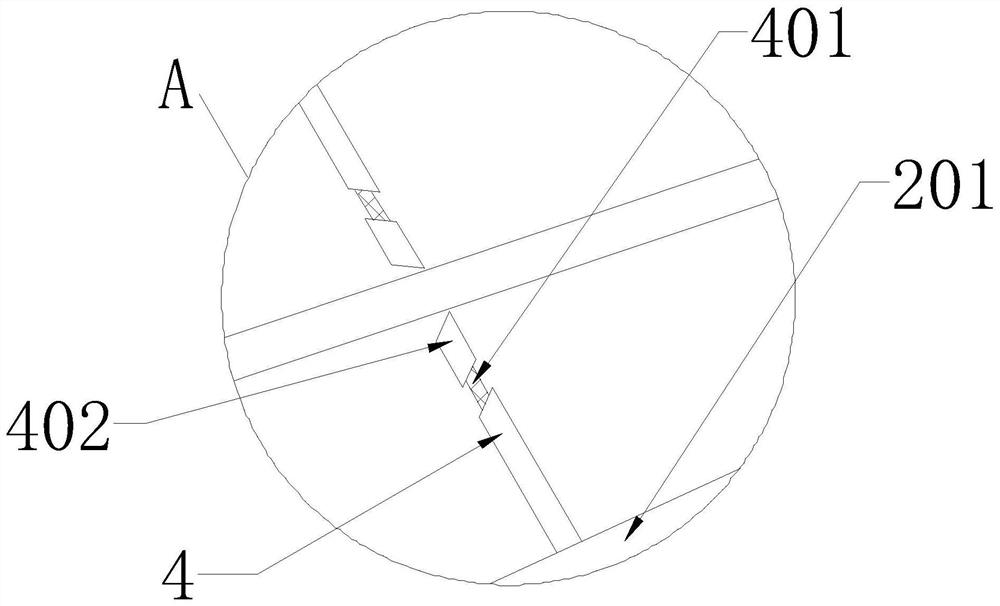

[0028] as attached figure 1 to attach Figure 10 Shown:

[0029] The present invention provides a textile rapid drying device capable of deflocculation, comprising: a drying box 1, a winding roller 101, a fixed frame 2, a feeding belt 201, a moisture-absorbing plate 202, a roller 203, a cleaning scraper 204, Conveying shaft 3, arc convex 301, air duct 302, storage slot 303, inner shaft 304, sheet 305, support plate 4, spring 401, scraper 402, threaded shaft 5, positioning slot 501 and through hole 502, drying A winding roller 101 is arranged below the inner wall of the box body 1, and a fixed frame 2 is fixedly arranged on the inner wall of the drying box body 1. A roller 203 is movable on the side, and the surface of the roller 203 is surrounded by a feeding belt 201. A cleaning scraper 204 is fixedly installed on the side of the fixed frame 2 far away from the drying box 1. The inner wall of the drying box 1 is movable. The feeding shaft 3, the surface of the feeding sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com