Power cable defect positioning and diagnostic method based on echo loss spectrum method

A return loss and power cable technology, which is applied in the field of precise positioning and diagnosis of local defects in power cables, can solve the problems that the severity of defects cannot be evaluated, the high-frequency signal components are few, and the recognition rate is not very high, etc., and achieve low cost and easy operation. Convenience and sensitivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

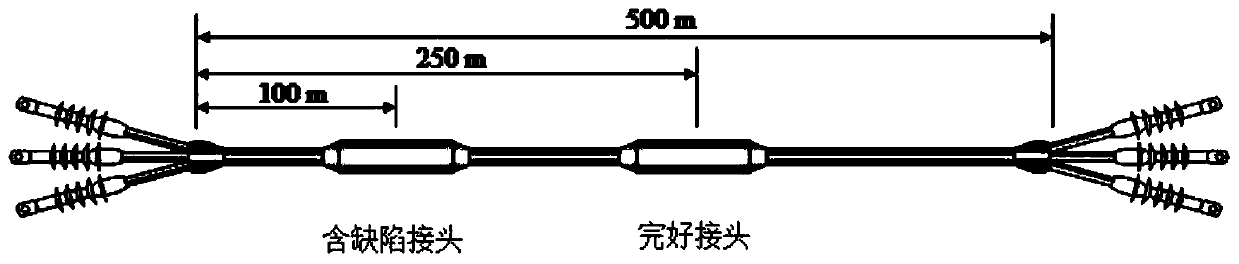

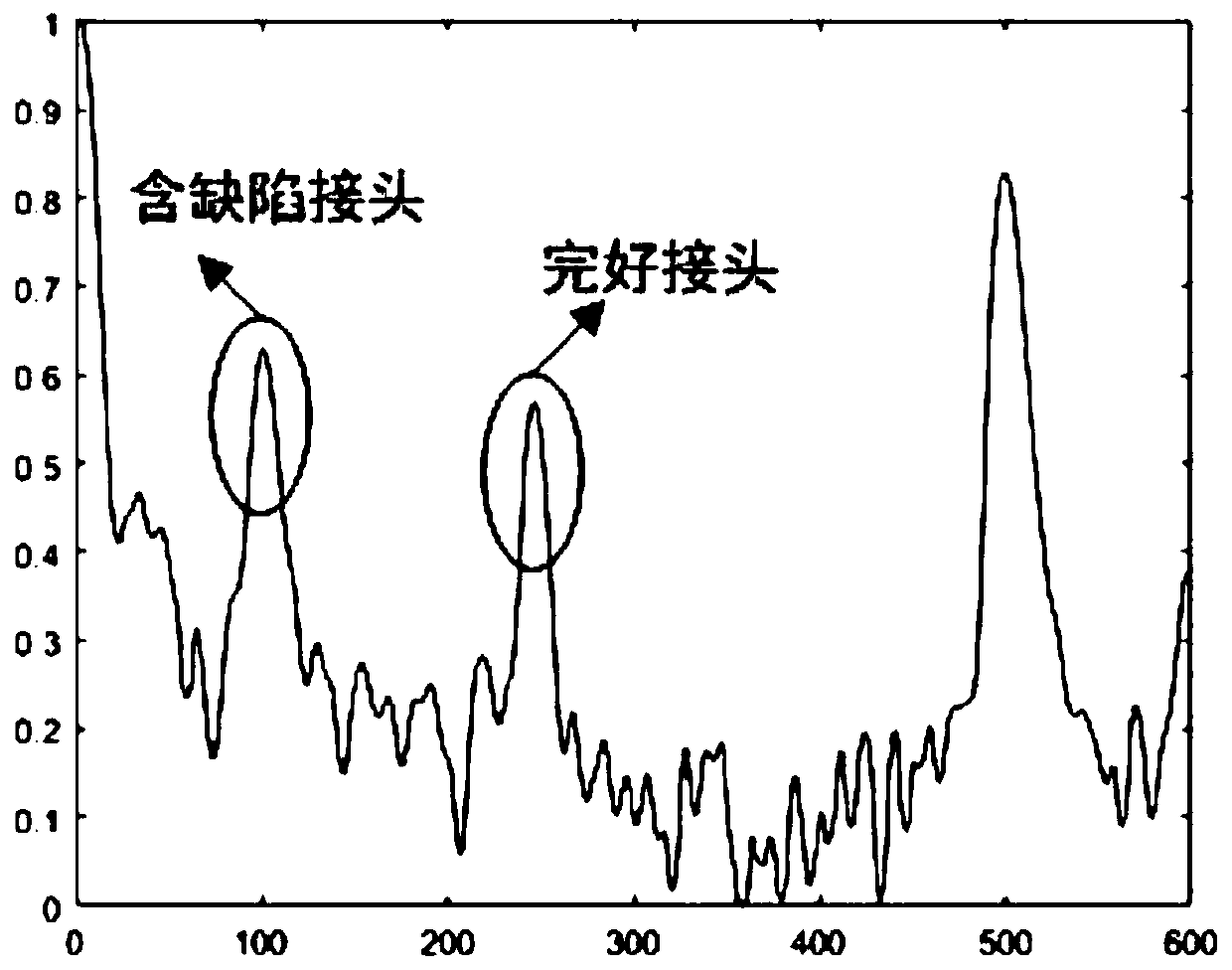

[0033] In this embodiment, the 500m long YJLV223×150 type 8.7 / 15kV XLPE power cable is taken as the research object, and the fault defect location diagnosis is carried out. Make intermediate joints at 100m and 250m of the cable, and artificially make defects at the joint position of 100m. The type of defect is that the copper connecting pipe is not polished. The specific schematic diagram of the test sample of the power cable to be tested is as follows figure 2 shown.

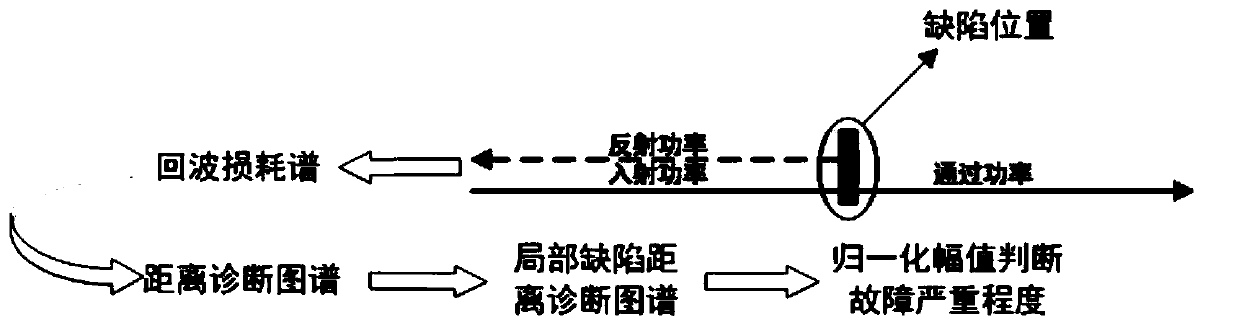

[0034] This embodiment locates and diagnoses the above-mentioned power cable defects, such as figure 1 shown, including the following steps:

[0035]S1 measurement data: transmit frequency sweep pulse V to the power cable under test i , measuring the reflected signal V r .

[0036] By sending sweeping pulses to the head end of the power cable to be tested, the incident signal is denoted as V i , measuring the reflected signal V reflected from the cable r , the frequency of the injected sweep pulse is f. ...

Embodiment 2

[0051] In this embodiment, a 100-m-long YJLV22×240 type 26 / 35kV XLPE power cable is taken as the research object to perform fault location diagnosis. Partial moisture treatment is carried out at 50m in the middle of the cable. The moisture treatment process is: inject 3ml of water into the outer sheath of the cable where the cable needs to be damp, through a syringe to simulate the local moisture defect of the cable. The schematic diagram of the specific test sample of the power cable to be tested is as follows: Figure 4 shown.

[0052] This embodiment locates and diagnoses the above-mentioned power cable defects, such as figure 1 shown, including the following steps:

[0053] S1 measurement data: transmit frequency sweep pulse V to the power cable under test i , measuring the reflected signal V r .

[0054] By sending sweeping pulses to the head end of the power cable to be tested, the incident signal is denoted as V i , measuring the reflected signal V reflected from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com