Electrostatic generator, method for increasing output power, charging method and wearable equipment

A charging method and generator technology, applied in the direction of induction generators, etc., can solve the problems of high equivalent charge density, low output power, high output power, etc., and achieve the effects of reduced charge density, high output power, and increased output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

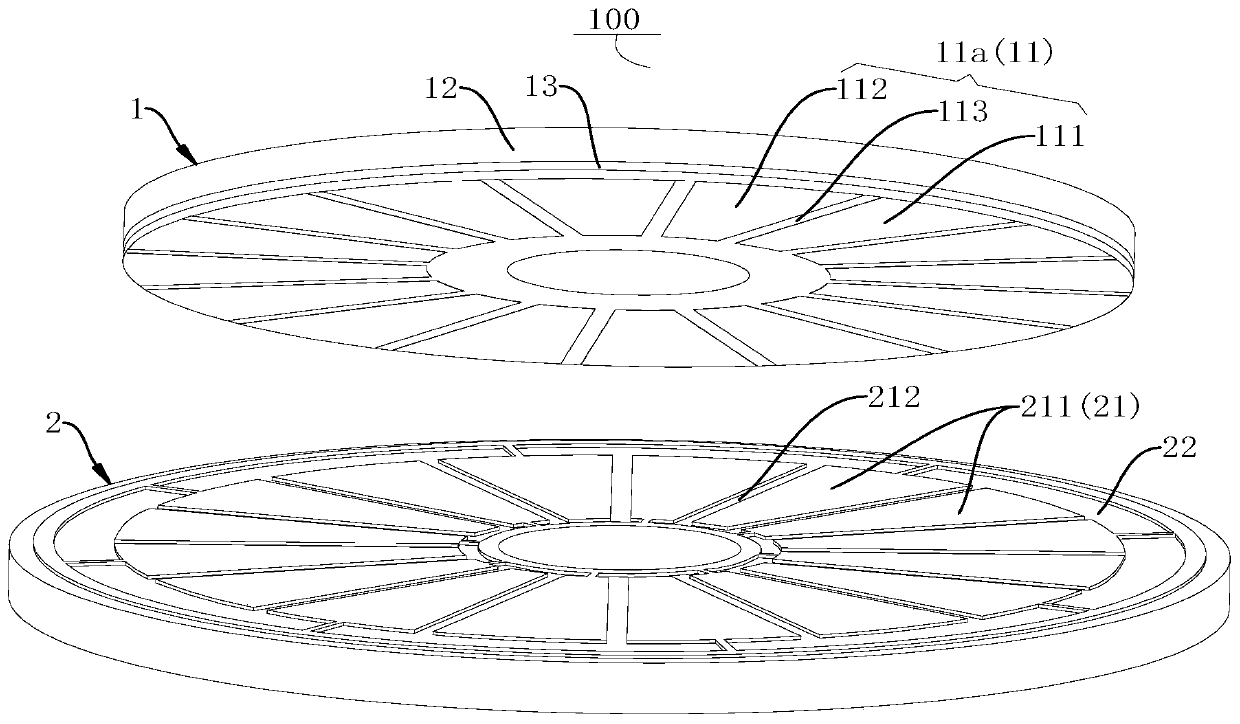

[0102] Embodiment 1 will show a rotary electrostatic generator.

[0103] Such as figure 1 As shown, the rotary electrostatic generator includes a rotor 1 and a stator 2 that are generally circular. Wherein the rotor 1 comprises: an electret film 11a, a rotor base 12 and an adhesive layer 13, wherein the electret film 11a is bonded on the rotor base 12 through the adhesive layer 13, and the electret film 11a is made of PTFE, And the thickness of the electret film 11a is 0.001-0.3 mm, and the rotor base 12 is made of foaming material. The charging voltage of the electret film 11a ranges from ±300V to ±4500V. The adhesive layer 13 adopts PI double-sided adhesive tape. The electret film 11a includes a plurality of first charged electrets 111 and a plurality of second charged electrets 112 of the same shape, and a plurality of first charged electrets 111 and a plurality of second charged electrets The bodies 112 are alternately arranged in the circumferential direction of the p...

Embodiment 2

[0106] Embodiment 2 also shows a rotary electrostatic generator.

[0107] The difference is that if Figure 9 As shown, the electret film 11a in Embodiment 1 is replaced by an electret plate 11b, the thickness of the electret plate 11b is 0.5-3 mm, and the rotor base 12 is eliminated. The electret plate 11b is made of CYTOP material. The voltage required for charging the electret plate 11b is relatively high, and the charging voltage ranges from ±5000V to ±30000V. The stator base 22 is made of foamed polypropylene.

Embodiment 3

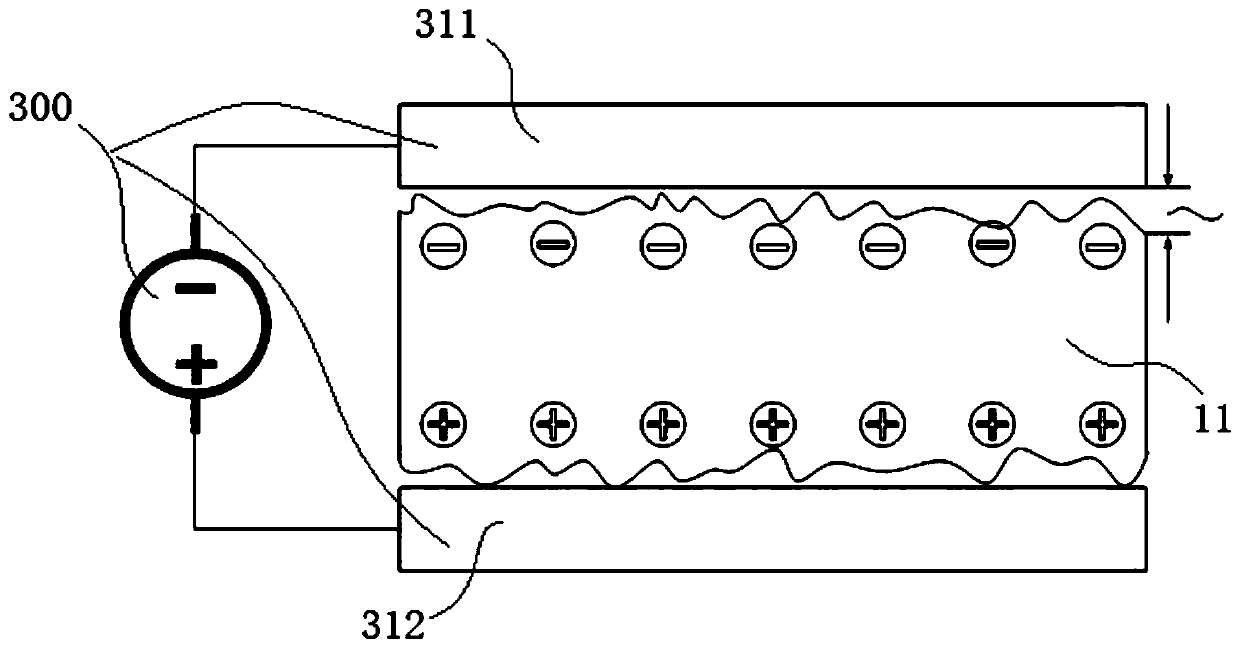

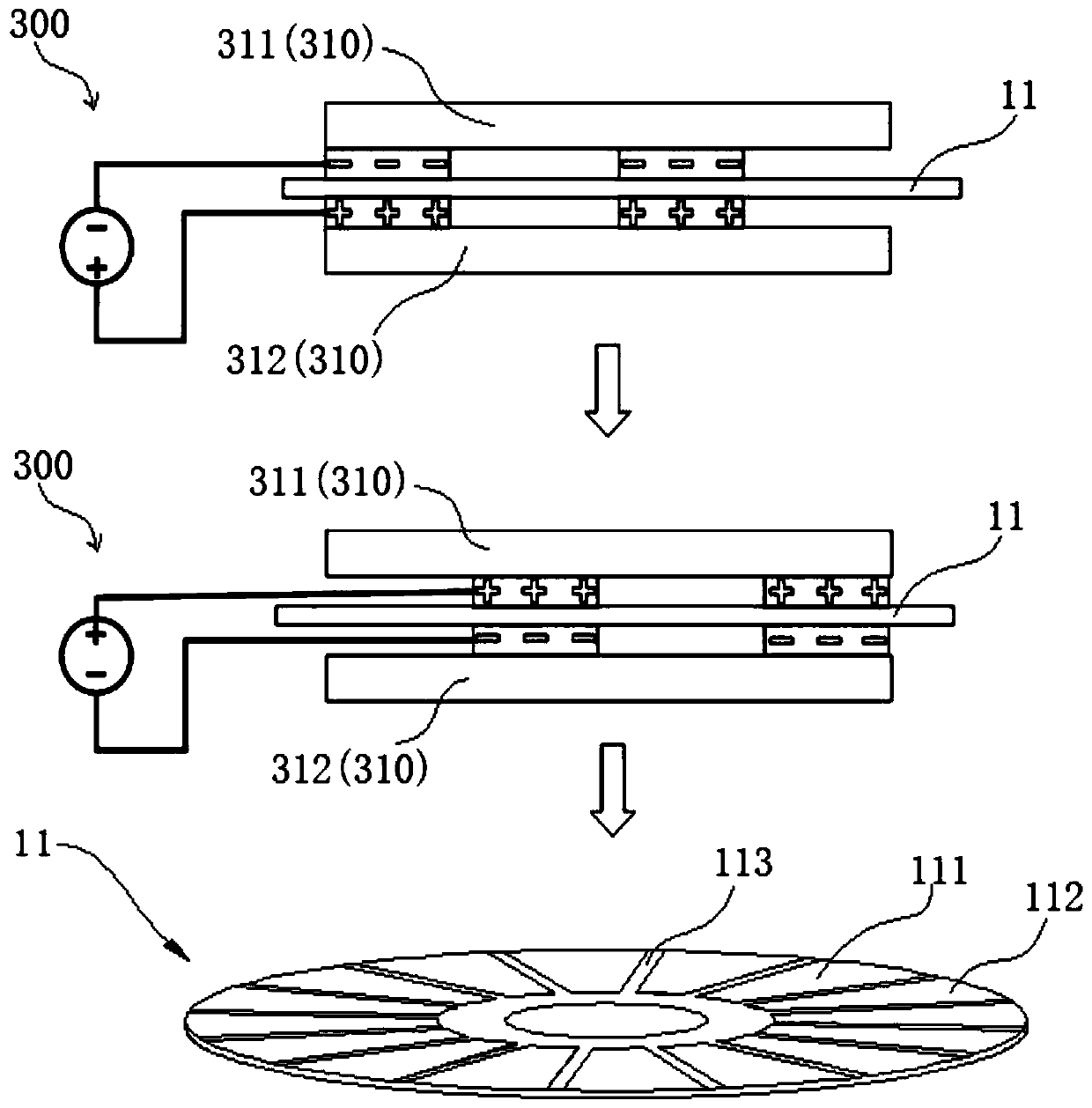

[0109] Embodiment 3 will show a patterned charging electrode 300 used for charging the electret film 11a of the rotary electrostatic generator in Embodiment 1 or the electret plate 11b in Embodiment 2.

[0110] Such as Figure 4a and Figure 4b As shown, the patterned charging electrode 300 includes a first charging electrode 311 and a second charging electrode 312 oppositely arranged, and the first charging electrode 311 includes a first electrode plate 311a, a first electrode 311b and a first positioning piece 311c, correspondingly, The second charging electrode 312 includes a second electrode plate 312a, a second electrode 312b and a second positioning piece 312c. The first electrode 311b is circumferentially arranged on the surface of the first pole plate 311a, and the second electrode 312b is circumferentially arranged on the surface of the second electrode 312a, wherein the shape of the first electrode 311b, the shape of the second electrode 312b and the first The shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com