Sanitary tissue paper

A tissue paper and hygienic technology, applied in the field of sanitary tissue paper, can solve the problems of small embossing space of sanitary tissue paper, oil leakage, oil content is difficult to be absorbed, etc., and achieve the effect of excellent absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

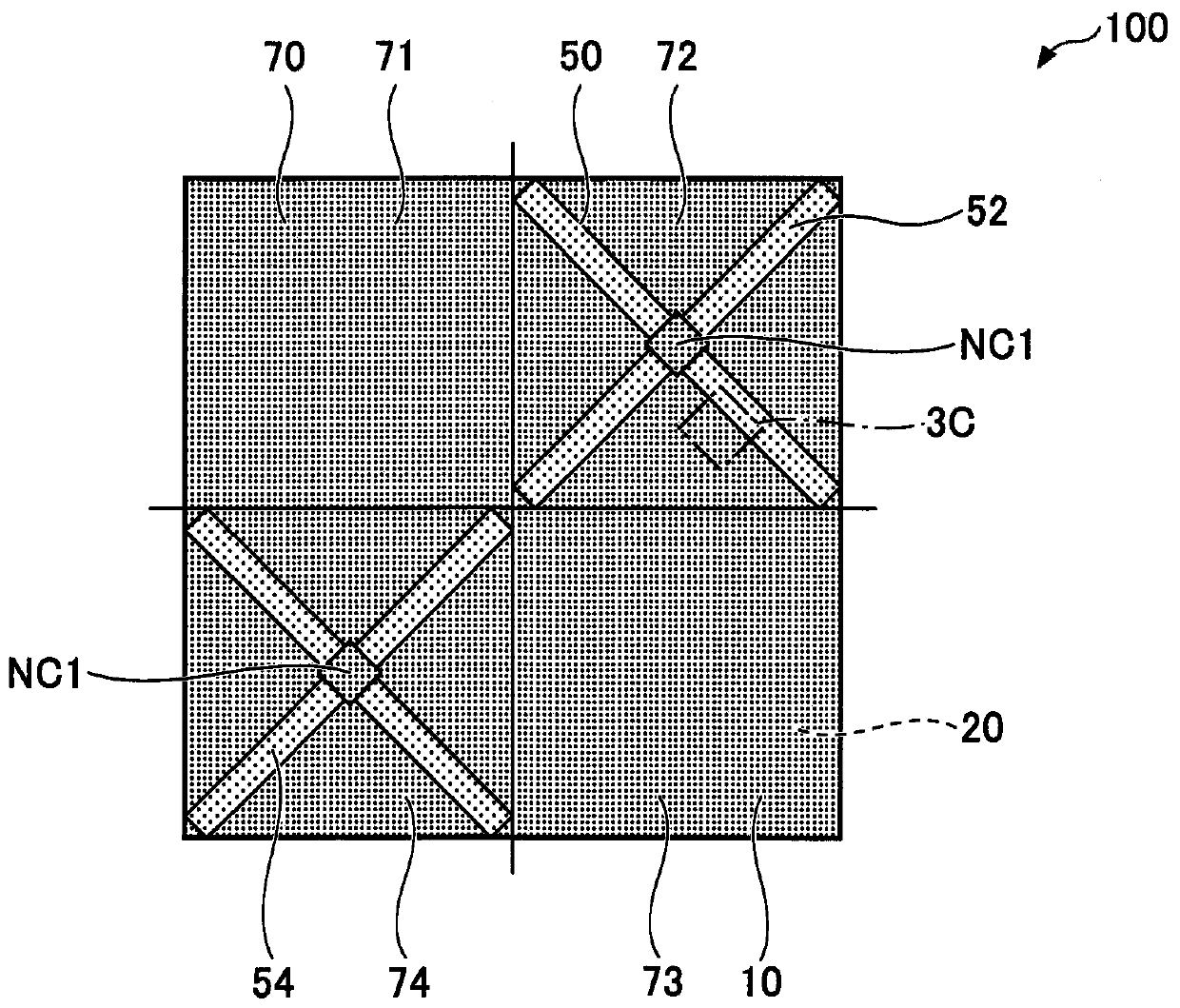

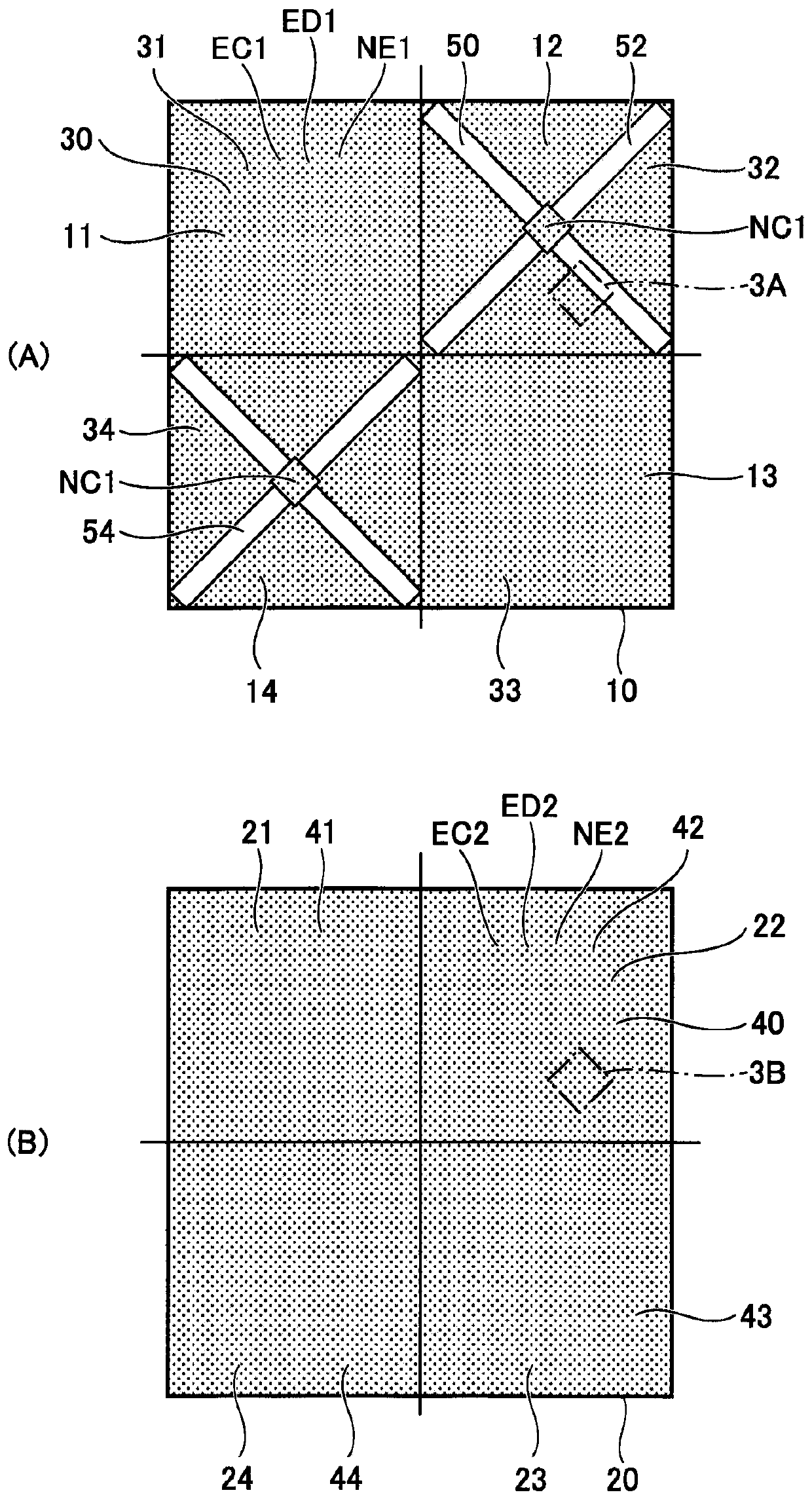

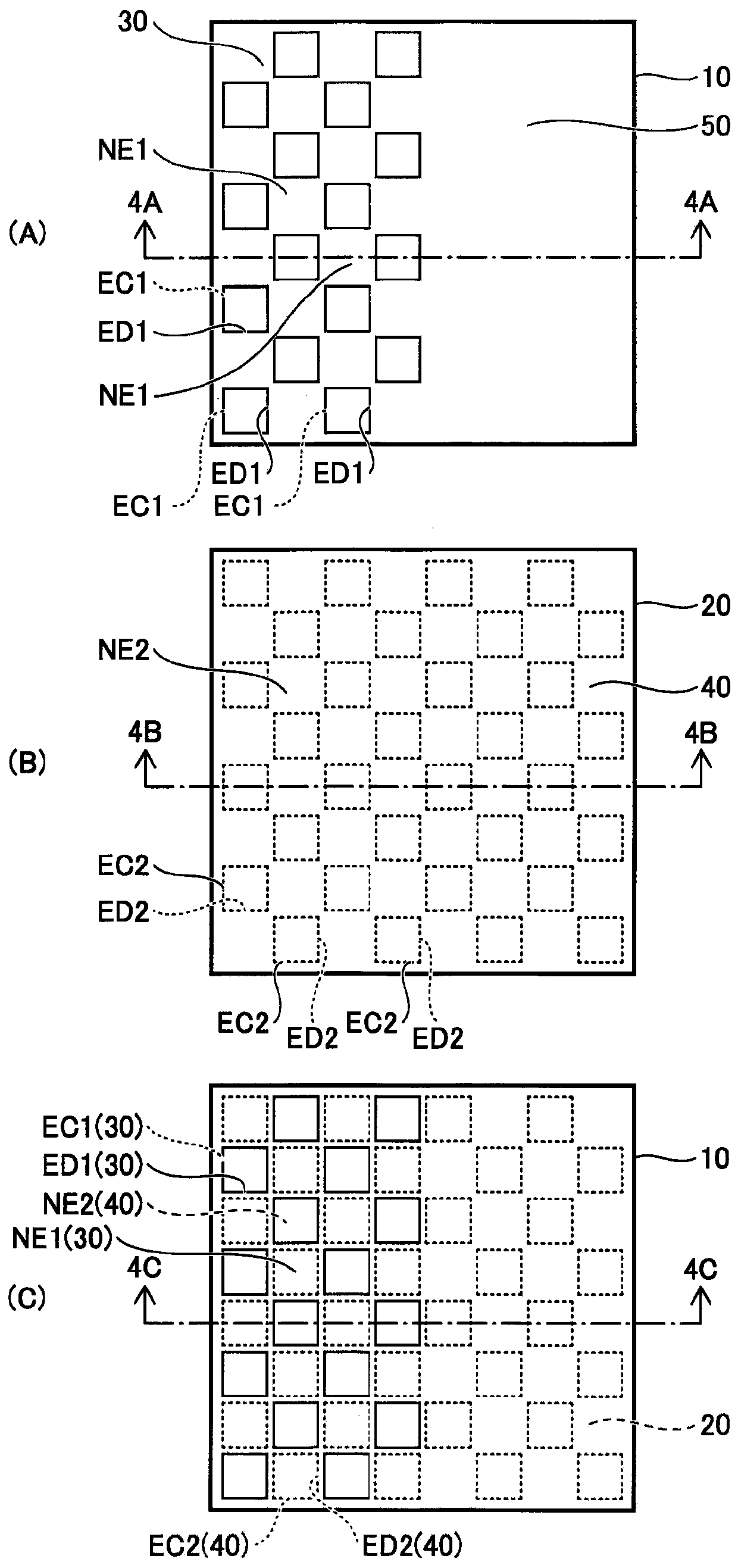

[0203] In Example 1, using Figure 1 to Figure 4 The shown kitchen paper 100 of the first embodiment. In Example 1, as the base paper, pulp with a fiber raw material of 100% by mass and a weight per square meter of 22.1 g / m 2 Two sheets of crepe paper 10, 20 of the base paper are stacked up and down (two layers). Regarding the embossing conditions, a nested form is adopted, and the area of the embossed convex parts EC1 and EC2 is set to 1.1mm 2 , the shape of the embossed convex portions EC1, EC2 is set to be a quadrangle, the pattern of the non-embossed portion 50 is set to be a cross and has no intersection in the cross, and the total number of embossed convex portions EC1, EC2 The number is 2090 / 144cm 2 , the glue coating area ratio of the embossed convex portion EC1 of the crepe paper 10 and the non-embossed convex portion NE2 of the crepe paper 20 (the coating area ratio of the non-embossed convex portion NE1 of the crepe paper 10 and the embossed convex portion EC...

Embodiment 2

[0205] In Example 2, using Figure 5 and Figure 6 The shown kitchen paper 100 of the second embodiment. In embodiment 2, the weight per square meter of base paper is 21.5g / m 2 , in the embossing condition, each pattern formed in the non-embossed regions 51, 53 of the non-embossed part 50 is made into a shape in which four elongated rectangles are arranged at predetermined intervals, and the non-embossed part Each pattern formed in the non-embossed regions 52 and 54 of 50 is made into a shape in which 12 elongated rectangles are arranged at predetermined intervals, and the total number of embossed convex parts EC1 and EC2 is 2105 pieces / 144cm 2 , assuming the total volume of all embossed convex parts EC1 and EC2 is 10759mm 2 , except that the area ratio of the non-embossed portion 50 is 10.7%, it is the same as in Example 1. Table 1 shows the conditions and results of Example 2.

Embodiment 3

[0207] In Example 3, using Figure 7 ~ Figure 10Kitchen paper 100 of the third embodiment shown. In Example 3, it is the same as in Example 1 except that the non-embossed portion 60 is formed on the crepe paper 20 . Table 1 shows the conditions and results of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com