Shock-adsorption rigid contact net for electrified rail traffic

A rigid contact and rail transit technology, applied in the direction of overhead lines, etc., can solve the problems of loss of pantograph slides and contact lines, increase in the amount of harmful dust, and decrease in operating efficiency, so as to reduce wear and metal dust pollution, and reduce arcing and arc ablation, reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

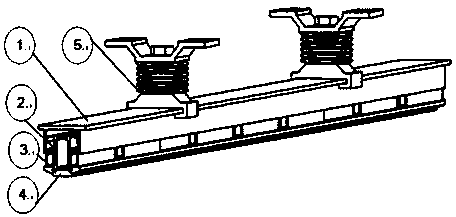

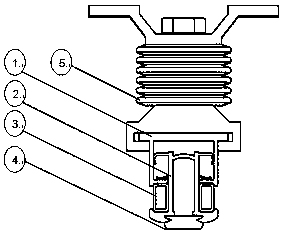

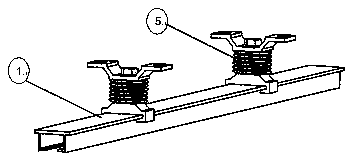

[0019] according to figure 1 The shock-absorbing rigid catenary for electrified rail transit shown is composed of five parts, with simple and reliable structure, easy installation, economical and durable, and easy maintenance. Among them, the fixed body (1) and the floating body (2) are made of aluminum profiles or similar conductive materials, each length is 12-15 meters, and can also be made according to customer requirements; the shock-absorbing elastic body (3) is made of rubber or similar shock-absorbing materials Manufacturing; the wide-format contact wire (4) is made of metal materials such as copper alloy or stainless steel, and the insulating support (5) is composed of claws, insulators and supports.

[0020] according to figure 2 The shown fixed body (1) and floating body (2) are used together, and the floating body (2) is used tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com