Fumigation facility using liquid or gas fuel

A gaseous fuel and liquid technology, applied in the field of vinegar production equipment, can solve the problems of environmental pollution, difficult to control the heat, etc., and achieve the effect of stable and controllable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

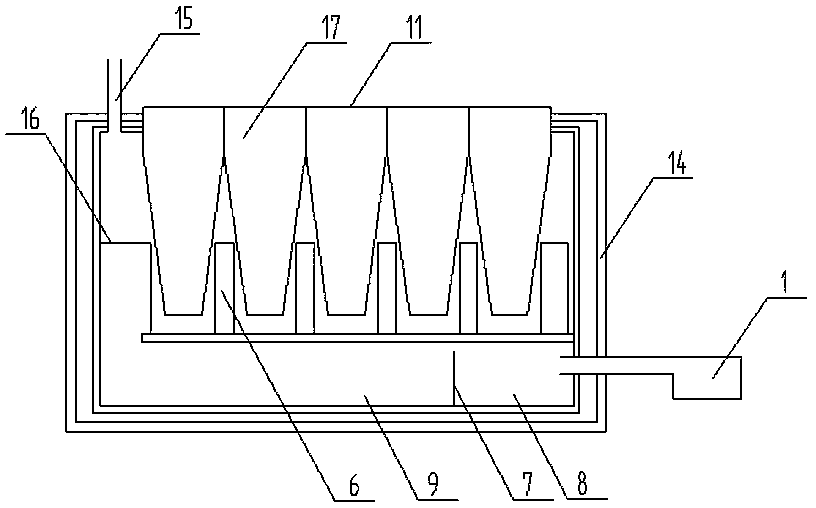

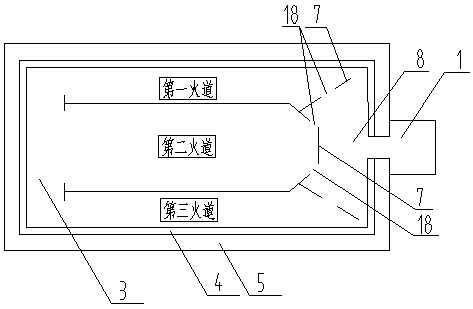

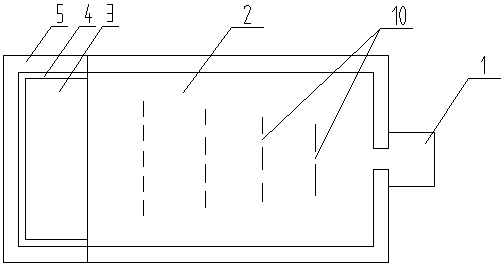

Embodiment 1

[0026] There are 5 smoked unstrained spirits tanks in total. The smoked pool is 2.0 meters long, 0.8 meters wide, and 0.8 meters deep. They are arranged side by side on a closed fire pit. The fire pit is a closed space that can be kept warm by the outer wall and the inner insulation material. The interior is divided into 3 main fire paths. At the front end of the main fire channel is the combustion chamber 8, which is connected to the burner 1 outside. The combustion chamber is equipped with three baffles / walls (left, right, and front). The width of the front baffle is slightly narrower than that of the main fire channel in the middle. The opening is located in the middle of the main fire channel in the middle; the left and right baffles are also slightly narrower than the left and right main fire channels, and there is an opening in the middle. The hot smoke generated by combustion is scattered into the main fire channels in three different directions: left, right and front. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com