Cuprous oxide semiconductor ceramic material and preparation method thereof

A ceramic material, cuprous oxide technology, applied in the field of cuprous oxide semiconductor ceramic materials and its preparation, can solve the problems of semiconductor ceramic material damage, failure, electrical corrosion resistance, chemical corrosion resistance and other problems, and achieve long service life , good constructability and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

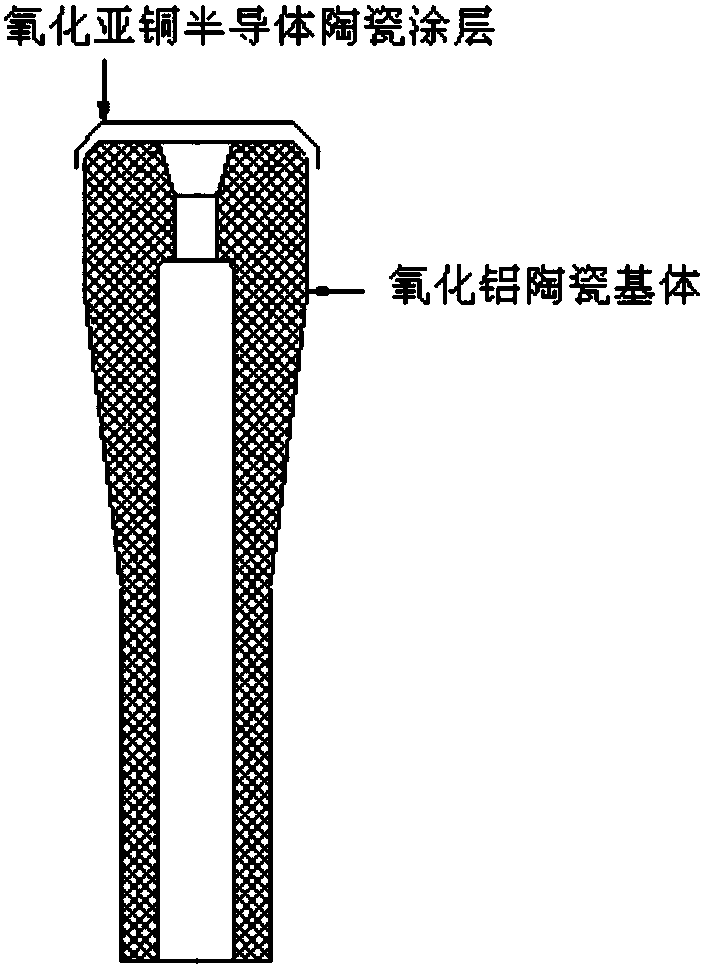

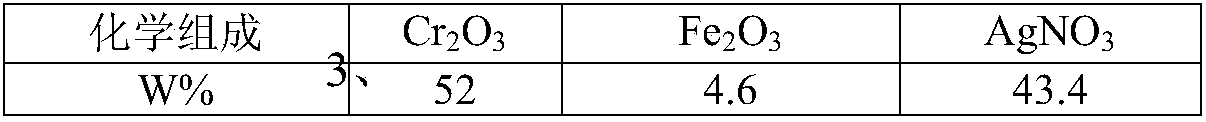

[0020] A cuprous oxide semiconductor ceramic material, the composition of the cuprous oxide semiconductor ceramic material includes copper oxide, copper powder, ferric oxide, chromium oxide, silver nitrate, mullite, quartz sand, spinel ; wherein the proportion of copper oxide is 25% to 39.8%, the proportion of copper powder is 15% to 25.4%, the proportion of ferric oxide is 0.5% to 0.8%, the proportion of dichromium oxide is 5% to 9%, The proportion of silver nitrate is 5%-7.5%, the proportion of mullite is 5%-7%, the proportion of quartz sand is 1%-5.5%, and the proportion of spinel is 1%-5%.

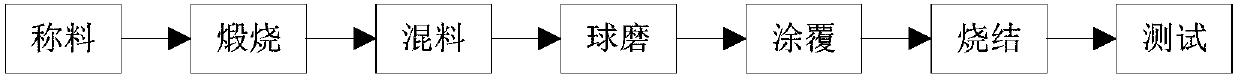

[0021] A preparation method of cuprous oxide semiconductor ceramic material, said method takes the following steps:

[0022] 1) The raw materials of copper oxide, copper powder, ferric oxide, chromium oxide, silver nitrate, mullite, quartz sand, and spinel are calcined and pretreated respectively, and sieved;

[0023] 2) Weigh and mix the sieved materials respectively, so that the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com