Assembling technology of equal-height double-box combined girder structure

A technology of composite beams and contours, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as unfavorable economic benefits, low lateral stiffness, and increased engineering investment, and achieve high synchronization, precision and performance requirements High, even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

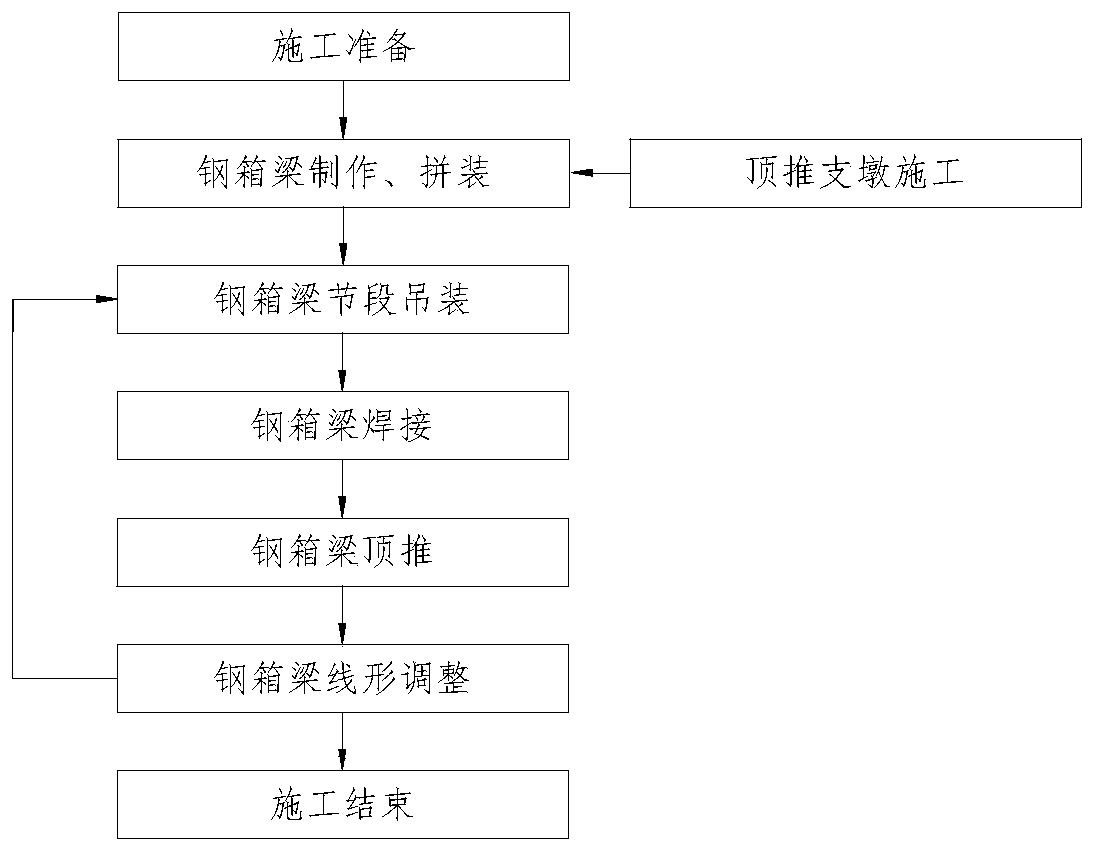

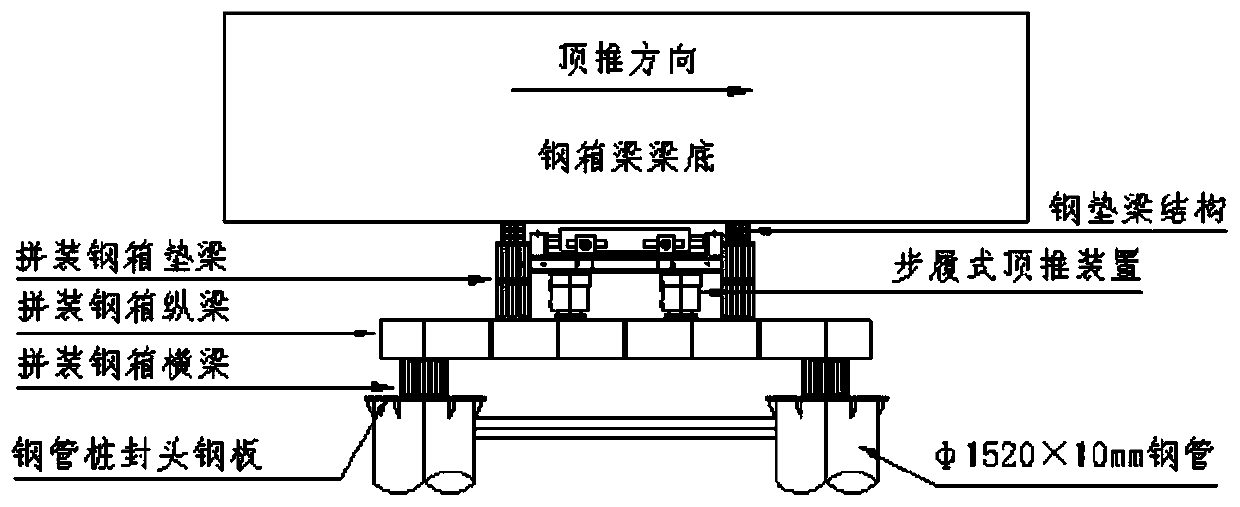

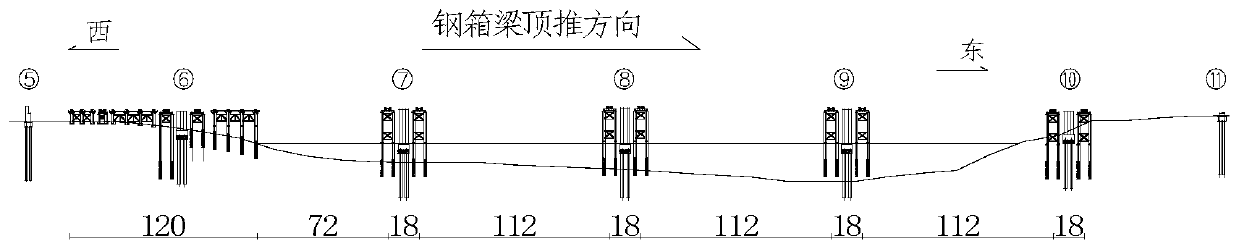

[0043] see Figure 1-4 , the assembly process of the double-box composite beam structure with the same height, including the following steps:

[0044] S1. Steel box girder transportation and lifting:

[0045] After the single-width steel box girder is assembled and painted, the finished steel box girder is transported to the steel box girder lifting area by a beam transporter, and then the steel box girder is connected to the welding platform through a traverse device. The steel box girder is lifted and hoisted to the welding platform, and the plane position and elevation are adjusted in place.

[0046] S2. The steel box girder is installed in place

[0047] S3. When installing the first section of the steel box girder, use the gantry crane to hoist the steel box girder of the first section to the corresponding position of the assembly welding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com