Two-stage walking speed reducer with brake shaft

A traveling reducer, with braking technology, applied in the direction of mechanical equipment, transmission, transmission parts, etc., can solve the problems of complex structure of reducer, unsatisfactory reducer, low efficiency of reducer, etc., to save operation space, The internal structure is novel and the output torque is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

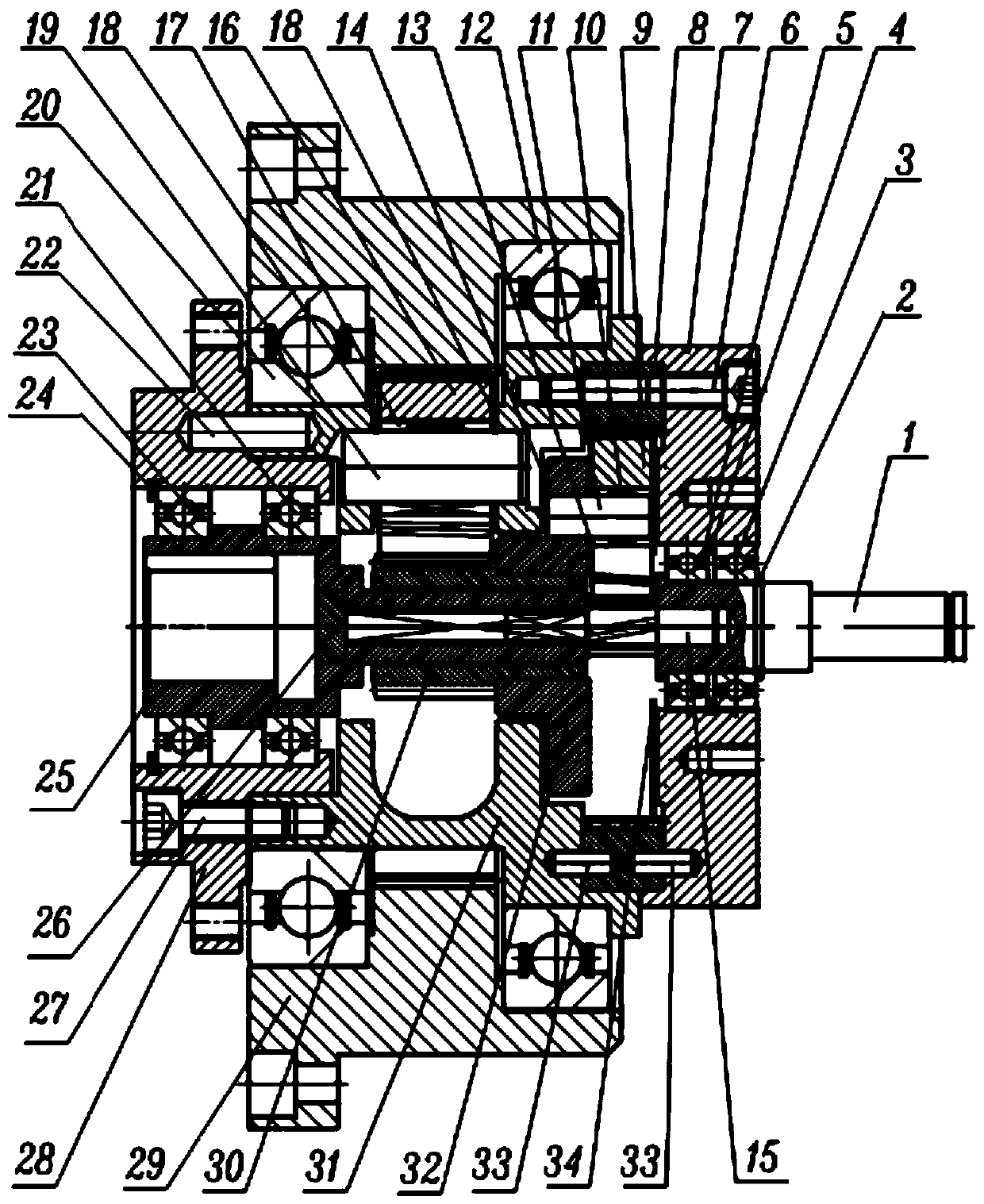

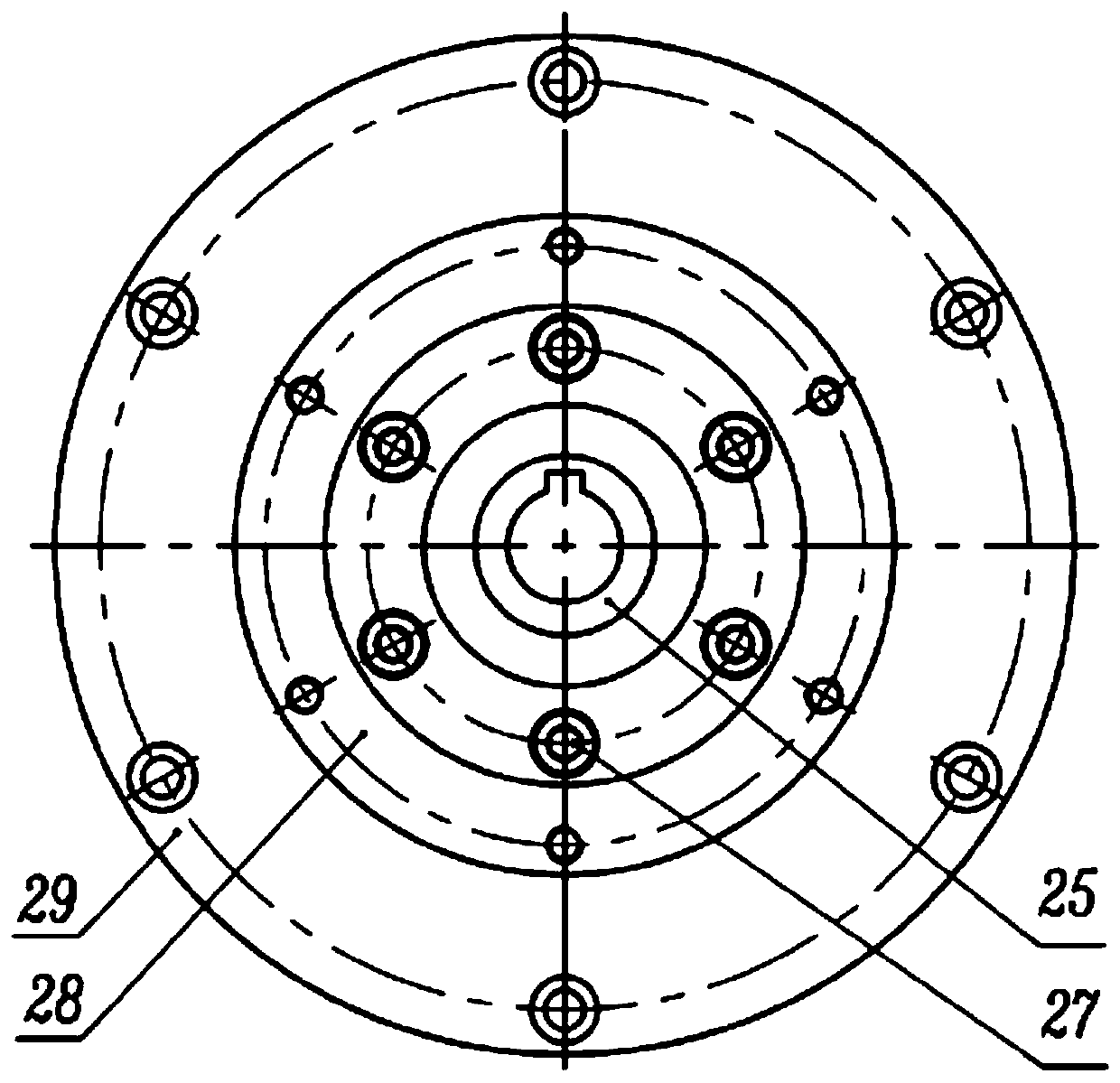

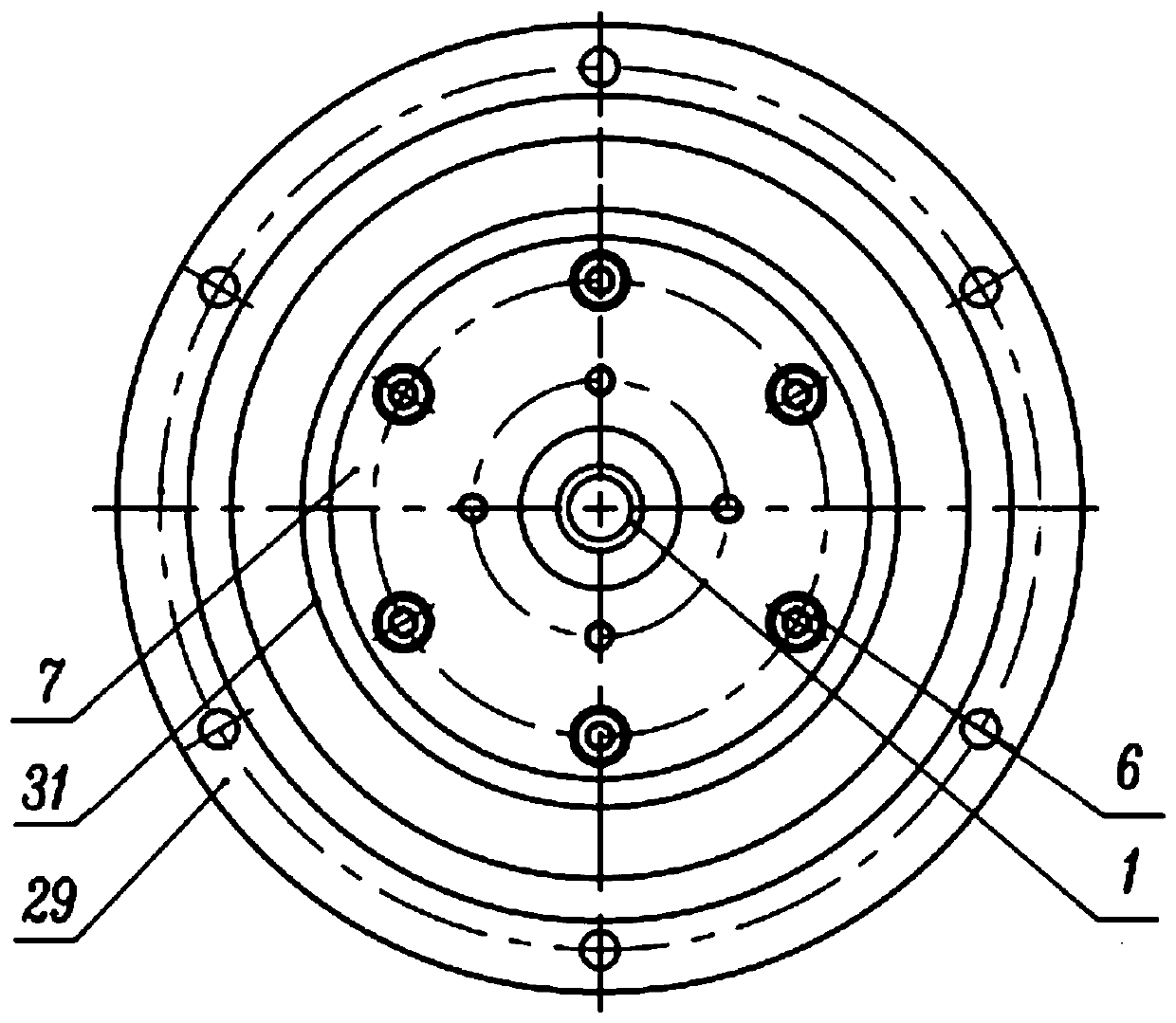

[0030] Embodiment 1: The present invention provides a double-stage travel reducer with a brake shaft, the structure of which is as follows figure 1 , 2 , as shown in 3, figure 1 It is the front view of the reducer of the present invention, figure 2 , 3 respectively figure 1 left and right views. From figure 2 At least the input shaft 25, the input flange 28 and the first-stage ring gear 29 provided on the left side of the reducer can be seen. image 3At least the brake shaft 1, the rear end cover 7 and the first-stage planet carrier 31 provided on the right side of the reducer can be seen, and the other side of the first-stage ring gear 29 can also be seen. see figure 1 , The reducer is also provided with a primary sun gear 30, a secondary sun gear 15, a secondary ring gear 8, a secondary planet carrier 32, a primary planetary gear 16 and a secondary planetary gear 9.

[0031] The input shaft 25 is provided with a first single row deep groove ball bearing 23 and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com