A Coking Circulating Ammonia Water Self-Cleaning Parallel Heat Extraction Device and Its Operation Control Method

A circulating ammonia water and operation control technology, which is applied in the direction of cleaning heat transfer devices, flushing, heat exchangers, etc., can solve the problems of ignoring the sticky characteristics of tar precipitates, failing to achieve the effect, and increasing the pressure difference between front and back, so as to reduce labor costs. Intensity, reducing the probability of clogging, reducing the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

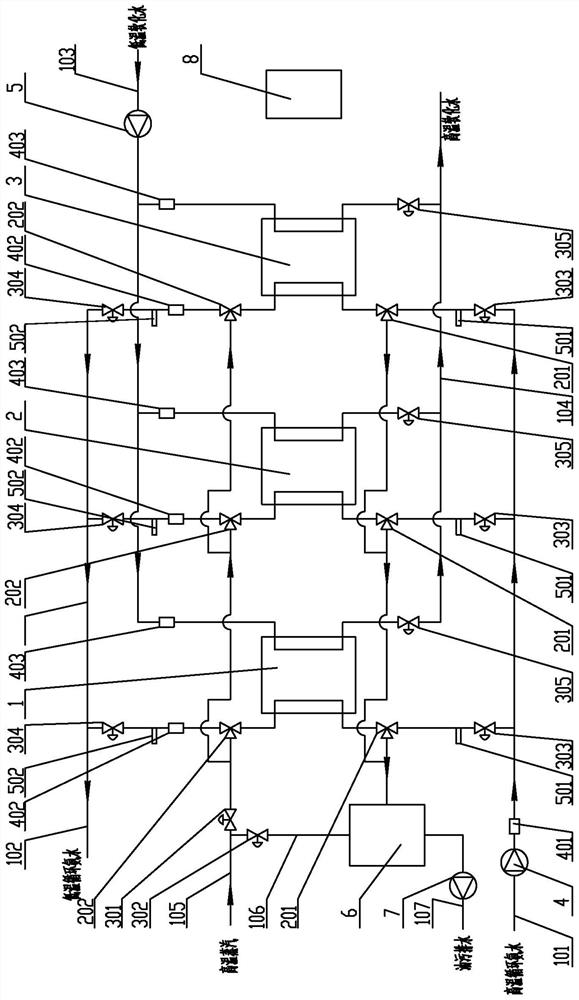

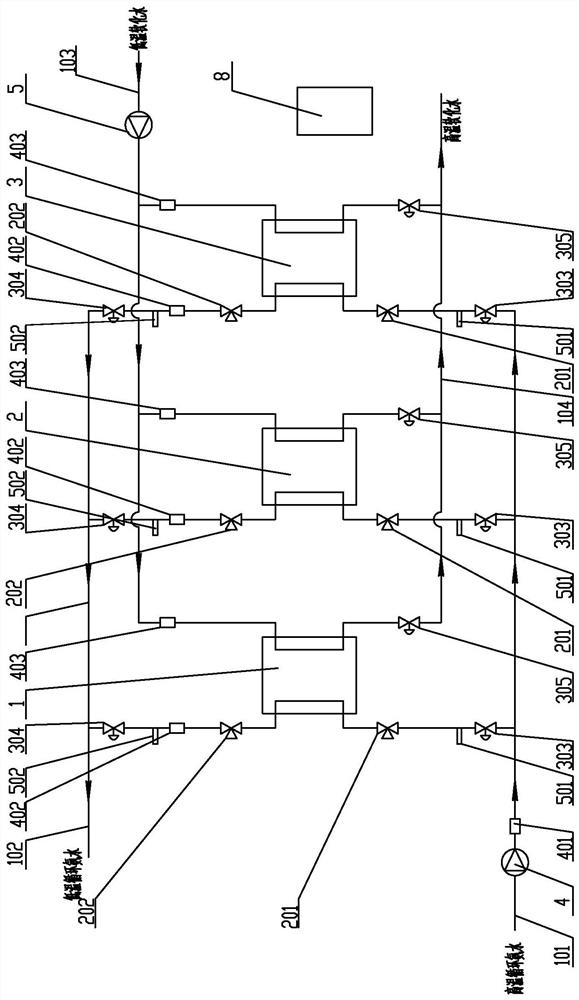

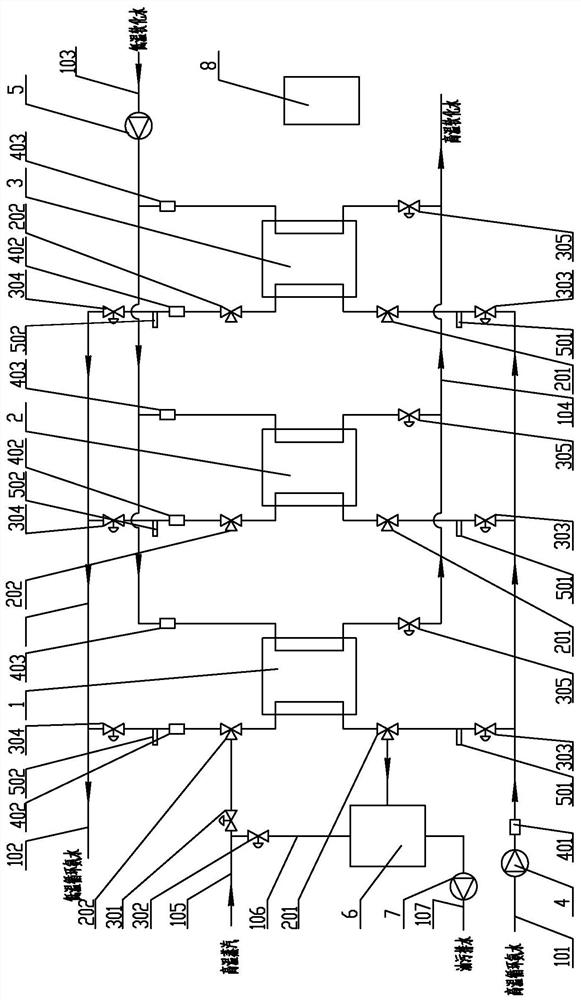

[0030] The following will combine specific embodiments and appendixes Figure 1-6 , clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the preferred embodiments of the present invention, rather than all the embodiments. Those skilled in the art can make similar modifications without departing from the connotation of the present invention, so the present invention is not limited by the specific embodiments disclosed below.

[0031] The invention provides a coking circulating ammonia water self-cleaning parallel heat extraction device (such as figure 1 shown), including the first heat exchanger 1, the second heat exchanger 2, the third heat exchanger 3, the circulating ammonia water pump 4, the softening water pump 5, the sewage collection tank 6, the sewage pump 7 and the central controller 8. A high-temperature ammonia water delivery pipeline 101 is connected in parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com