Planar multidirectional low-frequency electromagnetic vibration energy harvesting device

An electromagnetic vibration and energy harvesting technology, applied in the direction of electromechanical devices, electrical components, etc., can solve problems such as single application occasions, difficult voltage peripheral circuits, and high external excitation frequency requirements, and achieve the effect of increasing the working bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

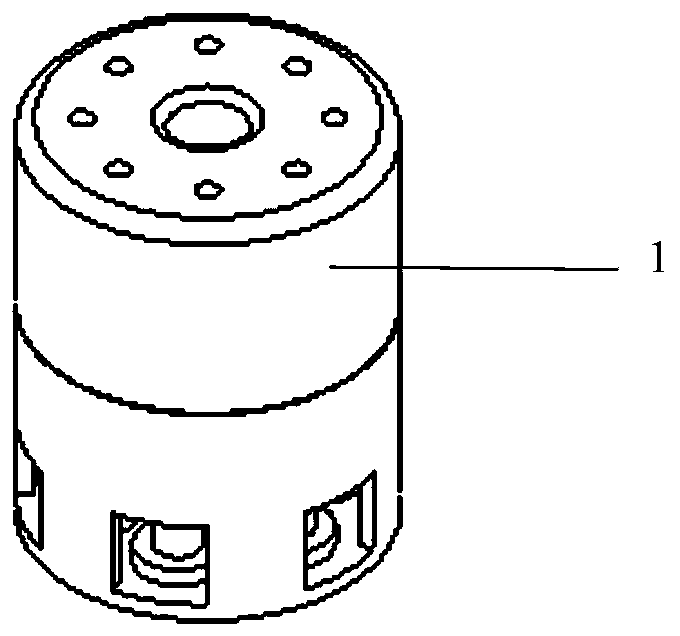

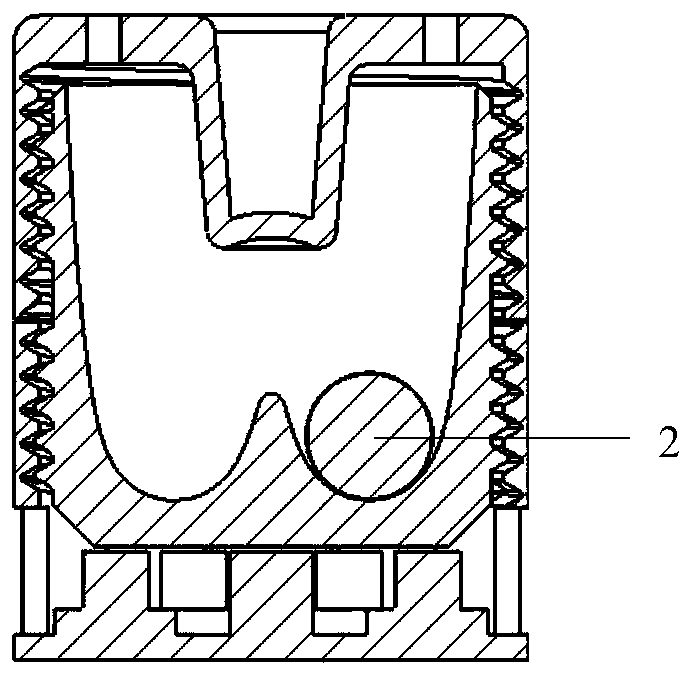

[0029] Such as figure 1 and figure 2 As shown, a planar and multi-directional low-frequency electromagnetic vibration energy harvesting device includes an upper cover 1, a curved surface structure in the middle and a coil base at the bottom;

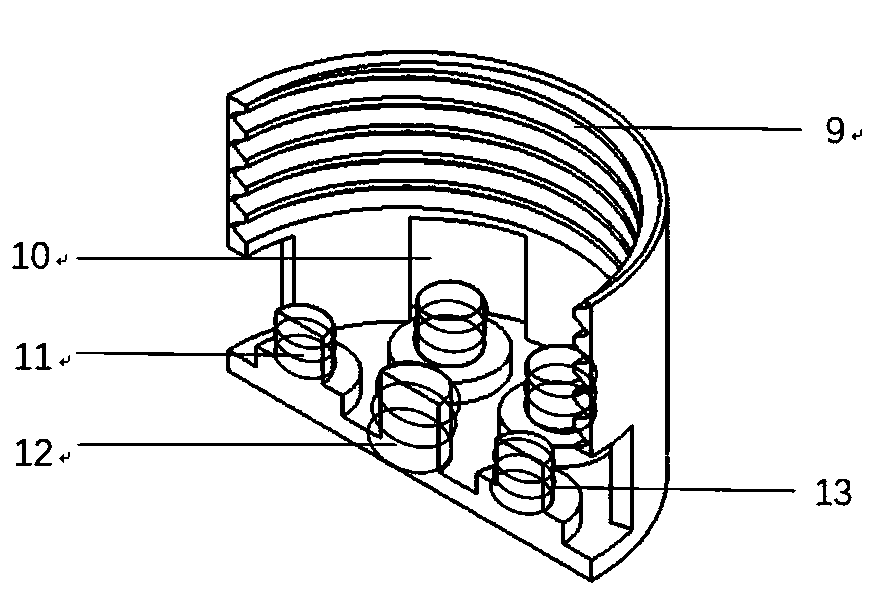

[0030] Such as image 3 and Figure 4 As shown, the coil base is a hollow cylindrical structure with an open top, and the bottom of the coil base is provided with 7 cylindrical bosses for inserting the multi-turn coil 10; the 7 cylindrical bosses include The first coil boss 12 in the center of the bottom of the seat and 6 second coil bosses (11, 13 among the figures) evenly distributed around the first coil boss; Corresponding positions are provided with openings 10, and internal threads 9 are provided on the inner wall of the side wall of the coil base;

[0031] Such as Figure 5 and Figure 6 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com