High-strength injection-molded zipper

A high-strength, zipper technology, applied in textiles, applications, fabrics, etc., can solve problems such as weak bonding strength, low-temperature embrittlement of plastic materials, and falling off of injection molded zipper elements, and achieve compatible bonding strength enhancement, surface performance optimization, Use consistent quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

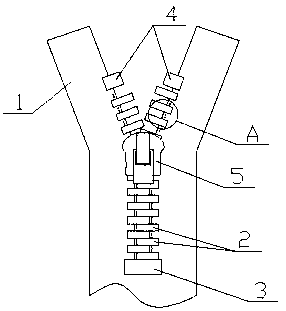

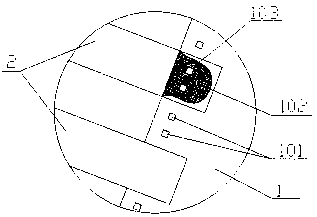

[0023] A high-strength injection molded zipper, comprising a zipper tape 1, a zipper element 2, a zipper element head 5, a zipper top stop 4 and a zipper bottom stop 3, and the zipper element 2 is evenly crossed and fixed on the zipper by injection molding On the cloth tape 1, the zipper top stop 4 is set on the top of the zipper element 2, the zipper bottom stop 3 is set on the bottom of the zipper element 2, and the zipper tooth head 5 is set on the zipper element 2 , it can be pulled up and down on the zipper element 2, and at the same time, the zipper element 2 can be meshed or separated accordingly. In addition, the zipper tape 1 is provided with a reinforced through hole 101, and the zipper tape 1 is woven from natural fibers. , natural fibers undergo a special surface treatment before weaving.

[0024] Further, the material of the zipper element 2 is engineering plastic.

[0025] Further, the material of the zipper tooth head 5 is stainless steel.

[0026] Further, th...

Embodiment 2

[0036] A high-strength injection molded zipper, comprising a zipper tape 1, a zipper element 2, a zipper element head 5, a zipper top stop 4 and a zipper bottom stop 3, and the zipper element 2 is evenly crossed and fixed on the zipper by injection molding On the cloth tape 1, the zipper top stop 4 is set on the top of the zipper element 2, the zipper bottom stop 3 is set on the bottom of the zipper element 2, and the zipper tooth head 5 is set on the zipper element 2 , it can be pulled up and down on the zipper element 2, and at the same time, the zipper element 2 can be meshed or separated accordingly. In addition, the zipper tape 1 is provided with a reinforced through hole 101, and the zipper tape 1 is woven from natural fibers. , natural fibers undergo a special surface treatment before weaving.

[0037] Further, the material of the zipper element 2 is engineering plastic.

[0038] Further, the material of the zipper tooth head 5 is stainless steel.

[0039] Further, th...

Embodiment 3

[0049] A high-strength injection molded zipper, comprising a zipper tape 1, a zipper element 2, a zipper element head 5, a zipper top stop 4 and a zipper bottom stop 3, and the zipper element 2 is evenly crossed and fixed on the zipper by injection molding On the cloth tape 1, the zipper top stop 4 is set on the top of the zipper element 2, the zipper bottom stop 3 is set on the bottom of the zipper element 2, and the zipper tooth head 5 is set on the zipper element 2 , it can be pulled up and down on the zipper element 2, and at the same time, the zipper element 2 can be meshed or separated accordingly. In addition, the zipper tape 1 is provided with a reinforced through hole 101, and the zipper tape 1 is woven from natural fibers. , natural fibers undergo a special surface treatment before weaving.

[0050] Further, the material of the zipper element 2 is engineering plastic.

[0051] Further, the material of the zipper tooth head 5 is stainless steel.

[0052] Further, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com