Mopping device and sanitation equipment

A mop and mop technology, applied in the field of environmental sanitation and cleaning, can solve the problems of small suction diameter, large power loss, affecting the service life of the ground, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

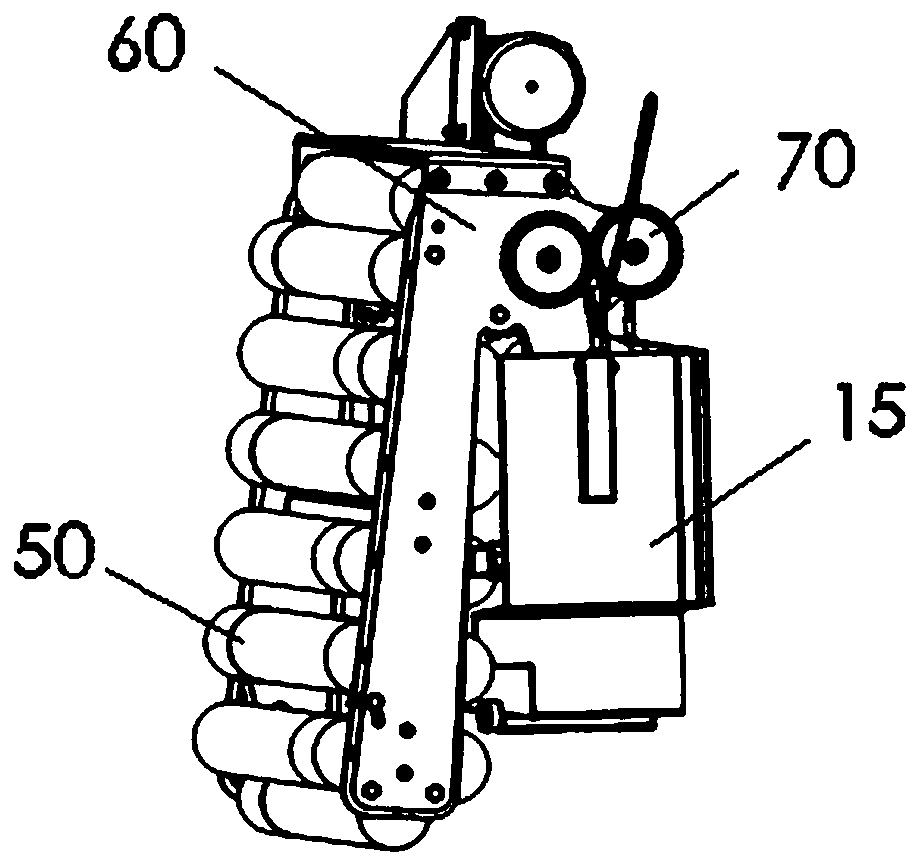

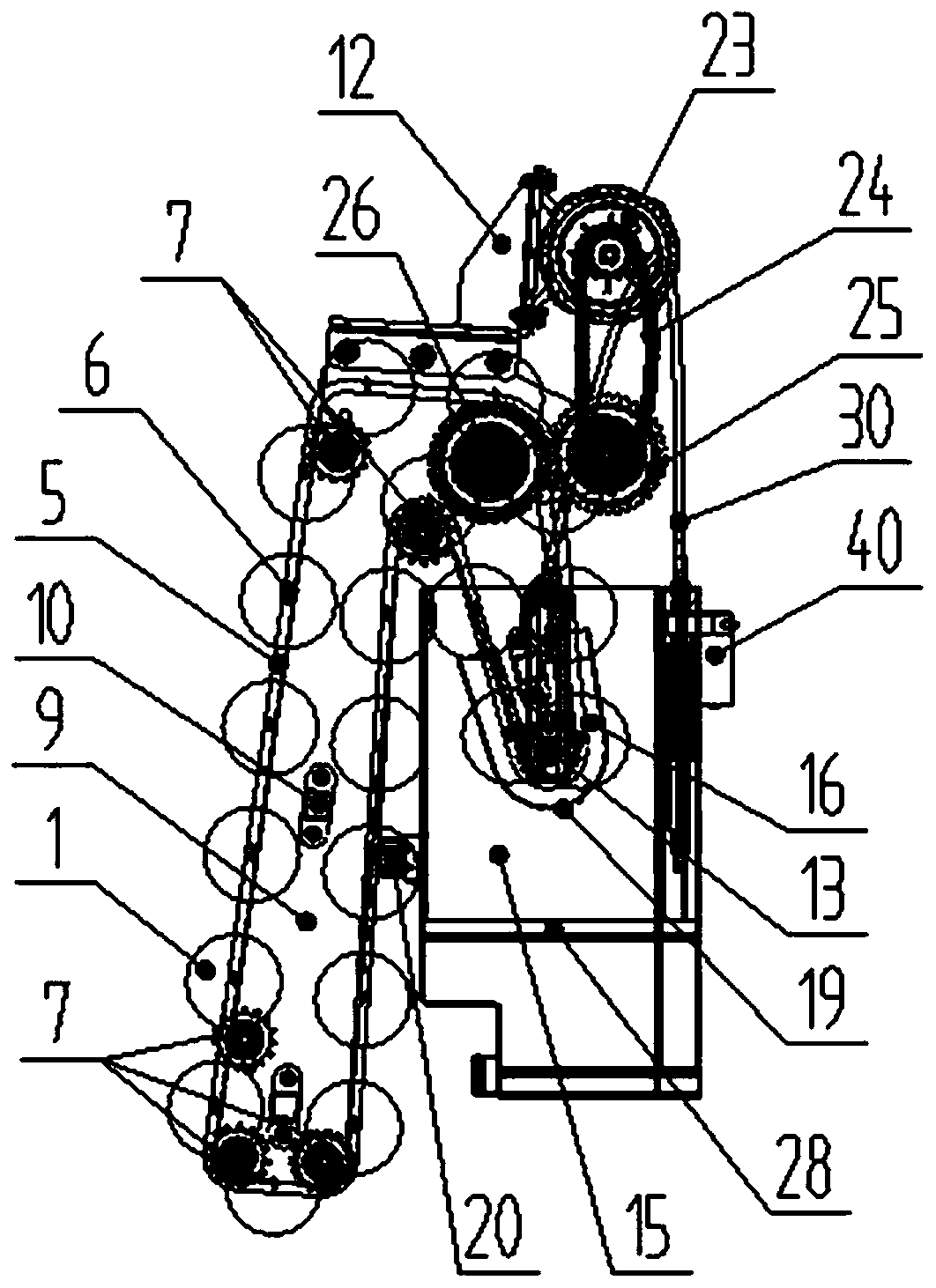

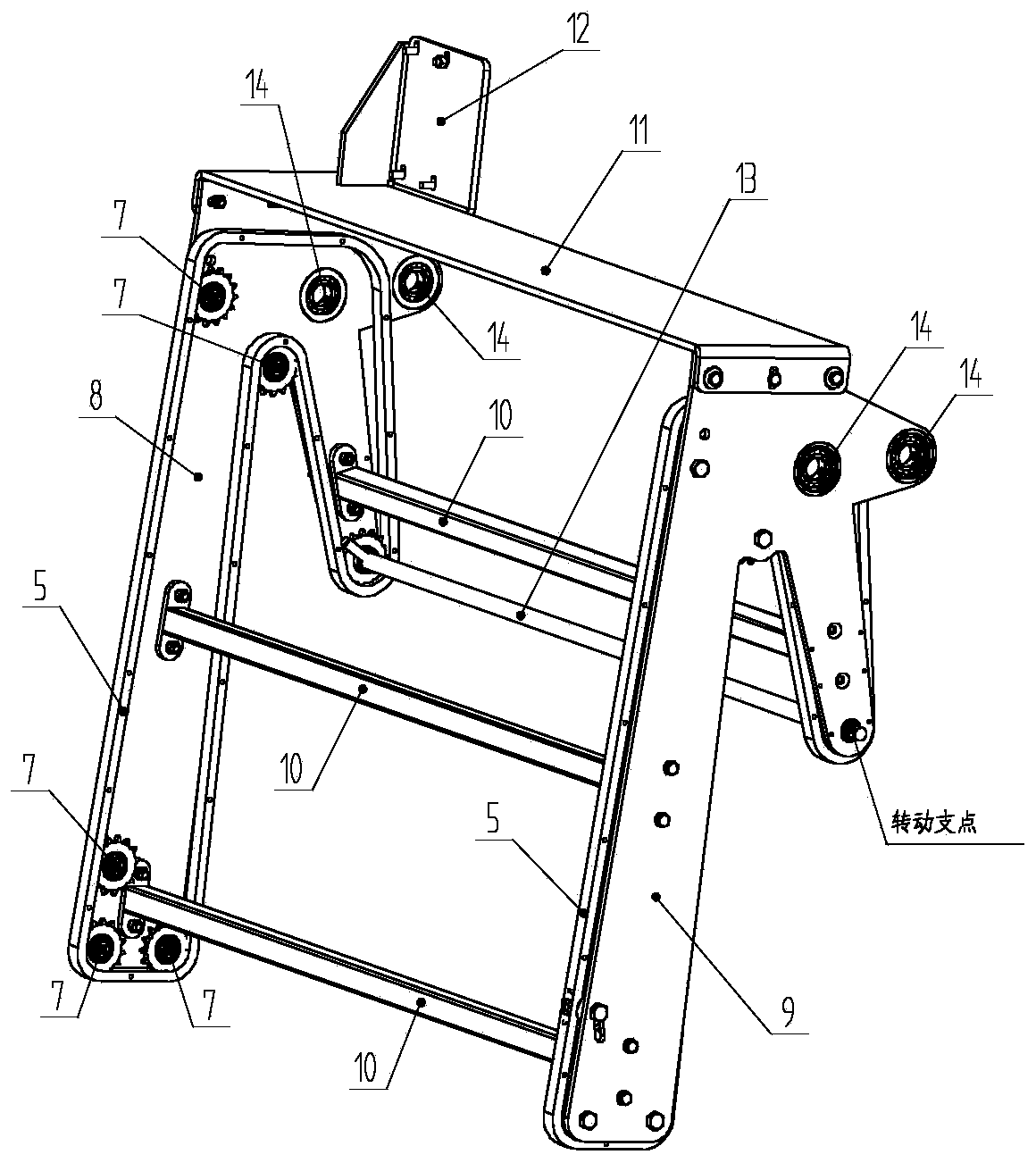

[0049] This disclosure provides a floor mopping device for sanitation machinery, aiming to solve the problems in the prior art mentioned in the above technical background, and to provide an innovative mopping device for sanitation machinery that can automatically cycle cleaning and dehydration The trace removal device can be loaded on various sanitation vehicles or equipment to work together.

[0050] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0051] Certain embodiments of the present disclosure will be described more fully hereinafter with reference to the accompanying drawings, in which some but not all embodiments are shown. Indeed, various embodiments of the disclosure may be embodied in many different forms and should not be construed as limited to the embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com