Equipment for cement production and processing

An equipment and cement technology, applied in the field of cement preparation, can solve the problems that the grinding effect is difficult to achieve the ideal state, the height of the grinding ball is limited, and the ore rejection rate is high, and achieves good grinding and crushing effect, short time consumption, impact and grinding. good effect of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

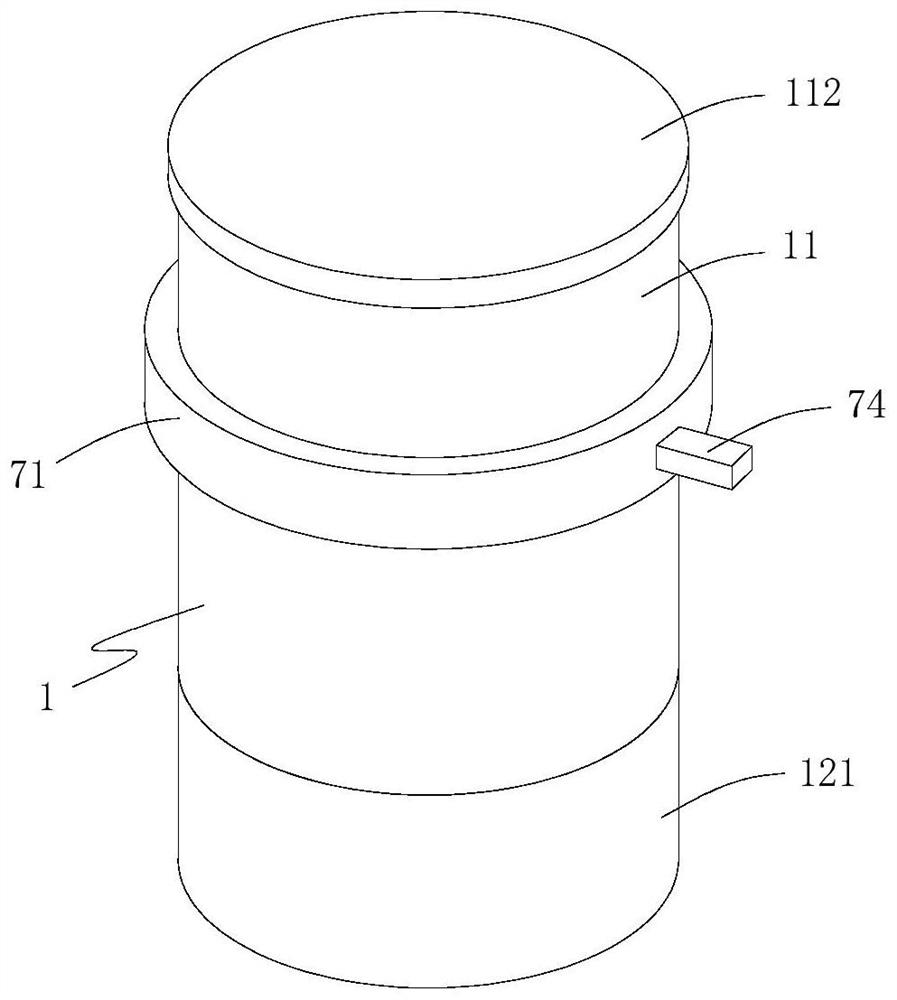

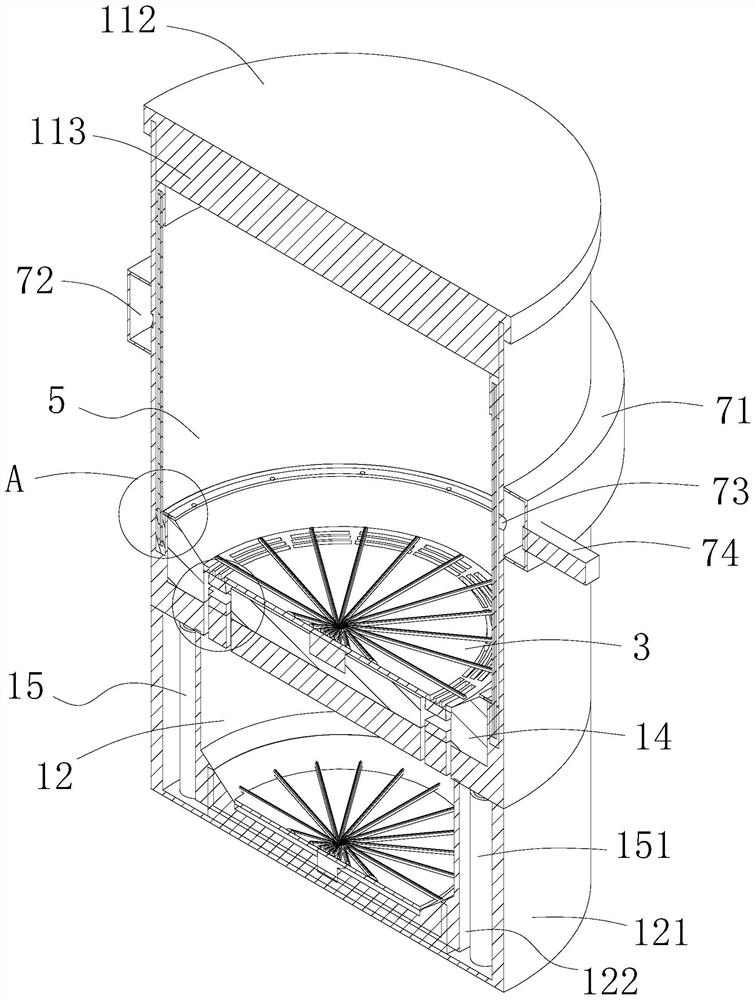

[0031] Such as Figure 1-10 As shown, a cement production and processing equipment includes a housing 1, an upper grinding chamber 11 and a lower grinding chamber 12 formed in the housing, a rotating disc 3 arranged in the upper grinding chamber, and a drive for driving the rotating disc to rotate. Part 4, the filter element 5 arranged on the side wall of the upper grinding chamber, the air extraction space 6 formed between the outer wall of the filter element and the inner wall of the upper grinding chamber, the air extraction parts communicated with the air extraction space, the device The crushing grinding piece 13 in the upper grinding chamber, the movable seat 14 in the upper grinding chamber that can move up and down, the displacement drive device 15 that drives the movable seat 14 to move up and down, and the displacement drive for driving the movable seat 14 to move up and down Device 15; the crushing and grinding part 13 is used to hit the filter part under the action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com