Miniaturized 1.2A electric-precipitation high-frequency high-voltage power supply

A high-frequency high-voltage power supply, electrostatic precipitator technology, applied in power supply technology, electrostatic separation, conversion equipment for intermediate conversion to DC conversion, etc., can solve the conflict between IP protection level and system heat dissipation, low protection level, and transformer eddy current loss. Large and other problems, to achieve the effect of improving IP protection level, prolonging service life, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

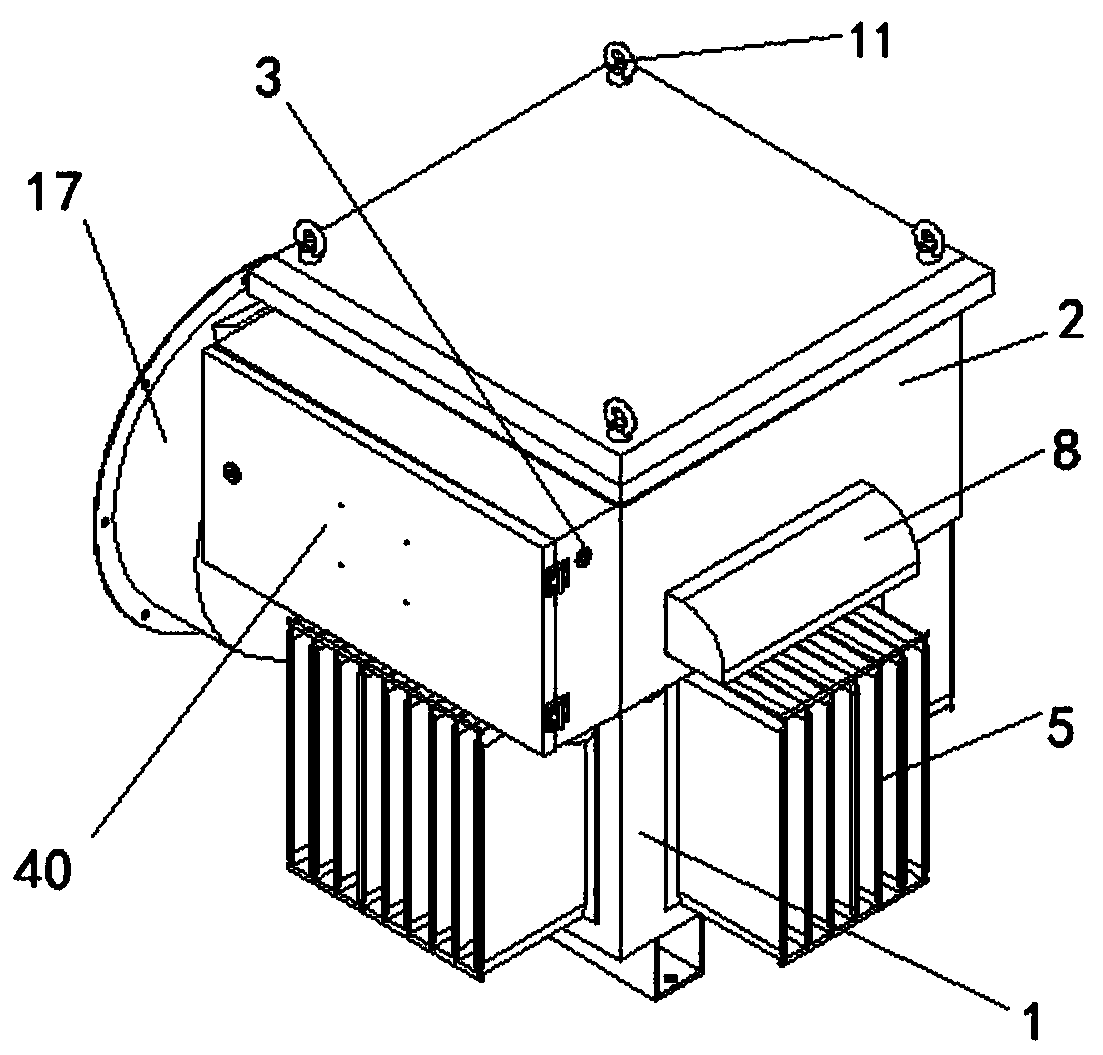

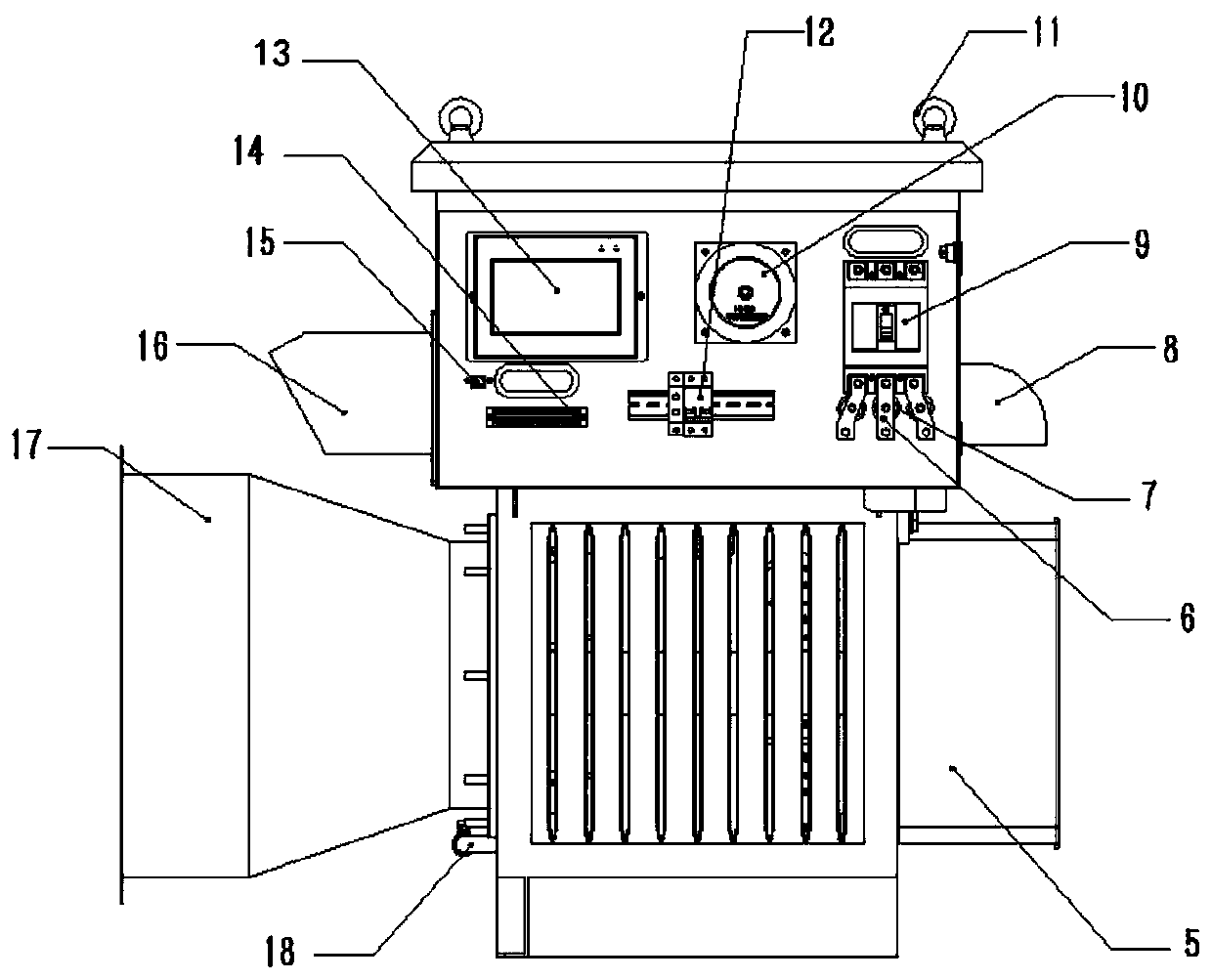

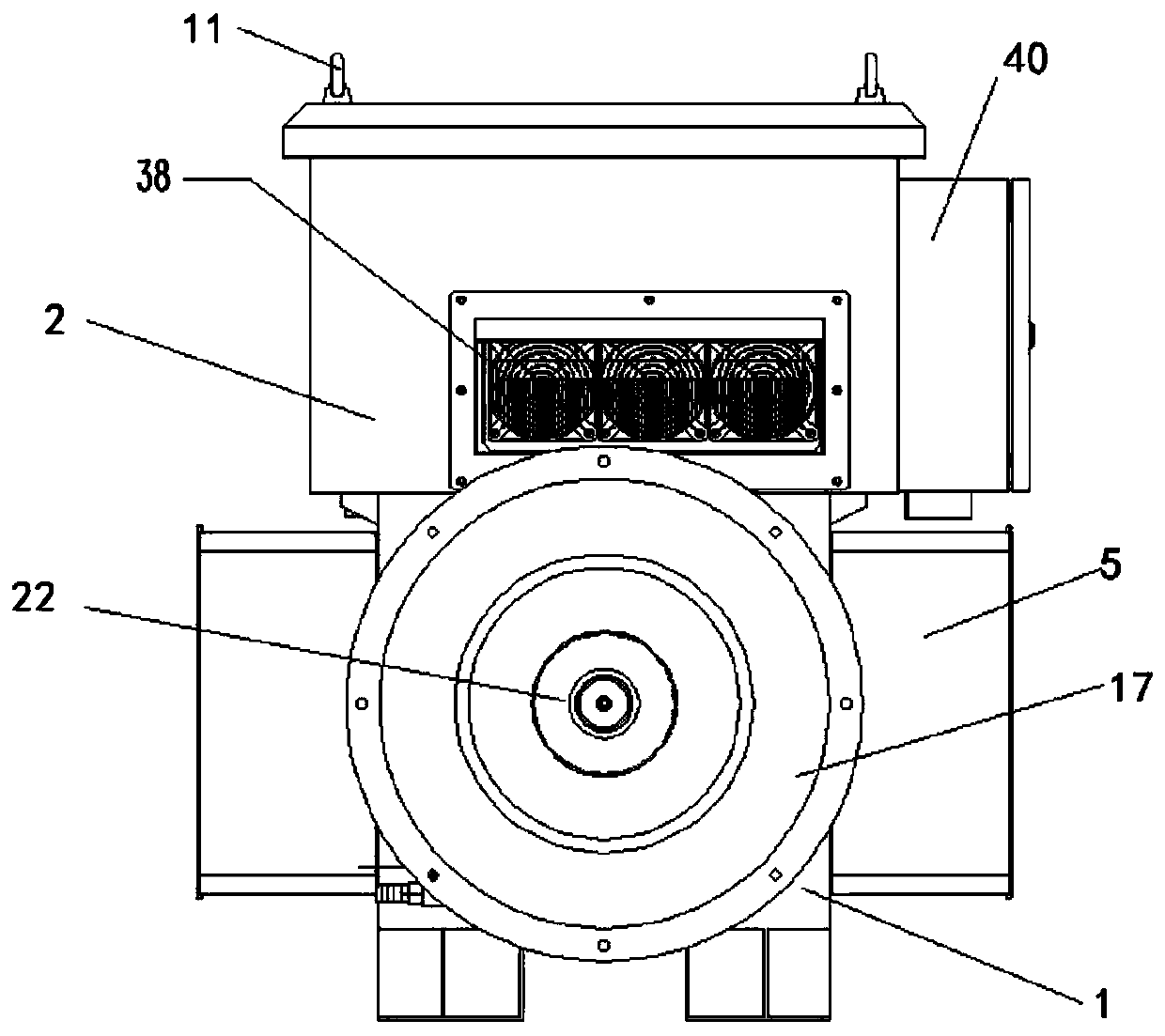

[0028] like Figure 1-7 As shown, a miniaturized 1.2A electric dust removal high-frequency high-voltage power supply includes a cabinet 2 and an oil tank 1 arranged up and down and fixedly connected; the top surface of the cabinet 2 is equipped with four lifting lugs 11 distributed in a rectangular shape. The sides of the cabinet 2 are respectively provided with an external junction box 40, an air inlet cover 8, and an air outlet cover 16, and the air inlet cover 8 and the air outlet cover 16 run through the side walls of the cabinet 2 respectively; The main control circuit assembly and the power circuit assembly arranged in upper and lower layers are installed in the interior, and the main control circuit assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com