Puller for rotor assembly assembling of aero-engine

A technology for aero-engines and rotors, applied in hand-held tools, manufacturing tools, etc., can solve the problems of inconvenient tooling management on the production site, increase safety production reliability, and high assembly requirements for rotor components, and achieve the goal of reducing safety production reliability Risk reduction, reduction of fixture design and production costs, stable and safe handling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

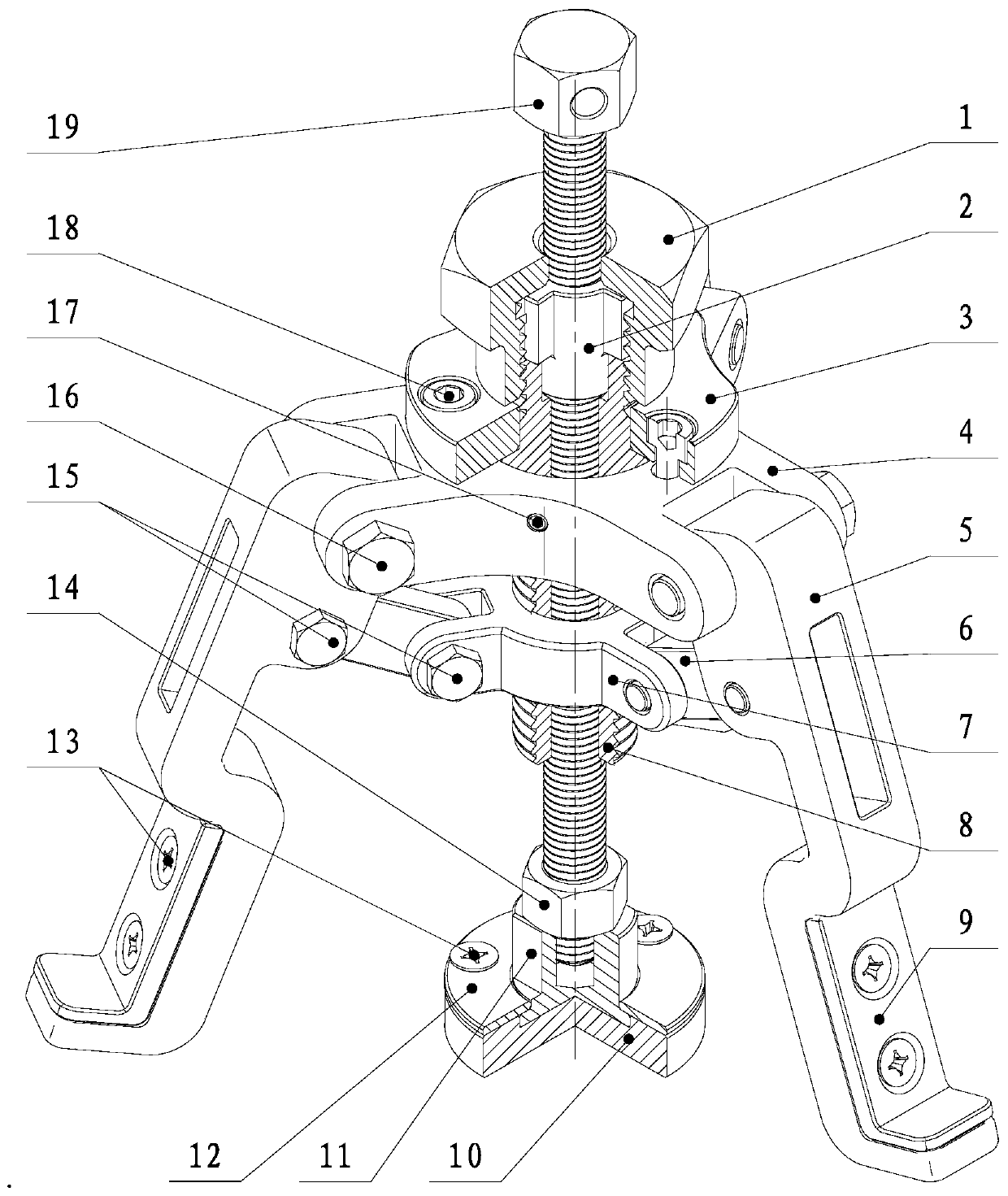

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail: 1 pressing cap, 2 wire sleeves, 3 pressing plates, 4 support blocks, 5 claws, 6 connecting rods, 7 movable blocks, 8 movable threaded rod sleeves, 9 claw stickers, 10 Force plate, 11 pressure head, 12 cover plate, 13M5 cross slotted screw, 14M16 lock nut, 15M6 limit screw, 16M8 limit screw, 17M4 lock screw, 18M6 inner hexagon screw, 19 ejector rod.

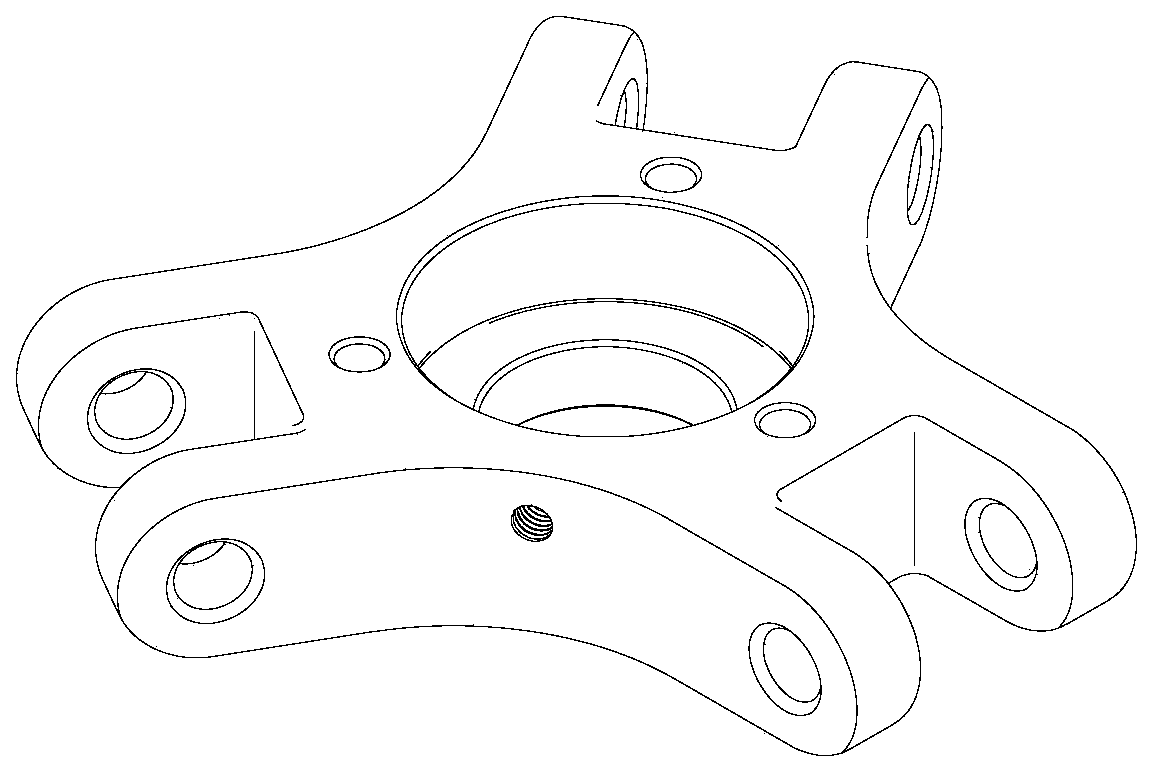

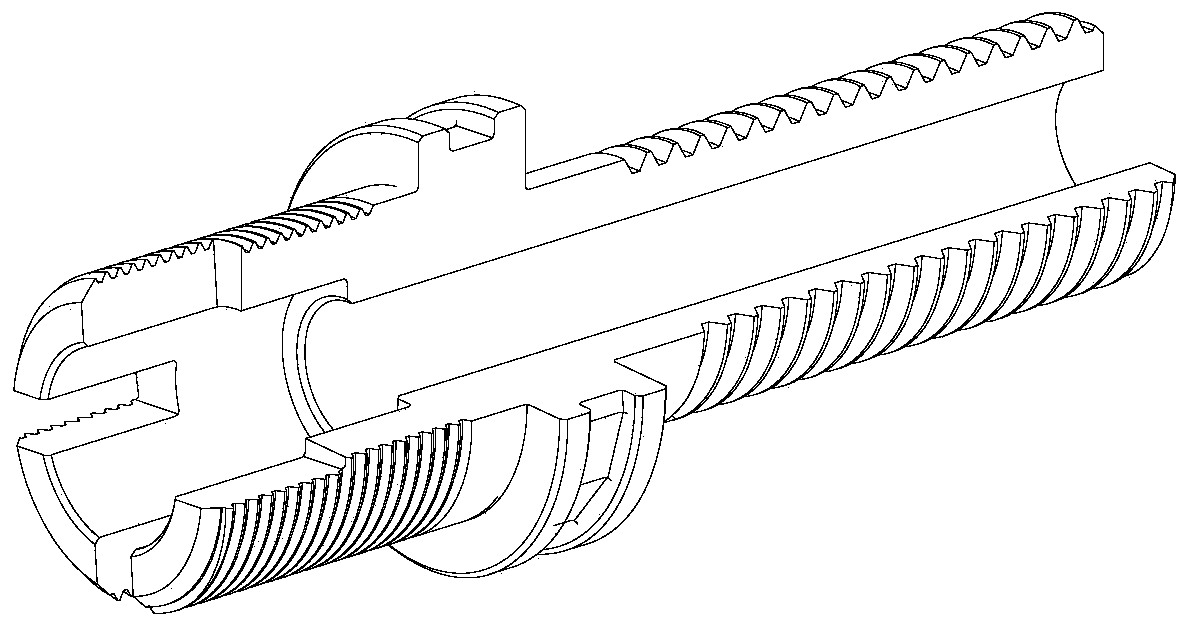

[0025] Such as figure 1 As shown, the tooling of the present invention includes a lifting adjustment element and a linkage tensioning element. Described pulling element comprises support block 4 (see figure 2 ), activity block 7 (see Figure 7 ), claw 5 (see Figure 4 ), dial and post 9 (see Figure 4 ), connecting rod 6, pressure plate 3, M8 limit screw 16, M6 limit screw 15, M6 inner hexagon screw 18, M5 cross slotted screw 13, M4 locking screw 17; the center position of support block 4 is provided with a step hole, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com