High-strength lightweight hub and making method thereof

A lightweight and high-strength technology, applied to wheels, wheels made of non-metallic materials, instruments, etc., can solve the problems of rough manufacturing, large inertial power assistance, and heavy weight, and achieve the effect of reducing weight and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

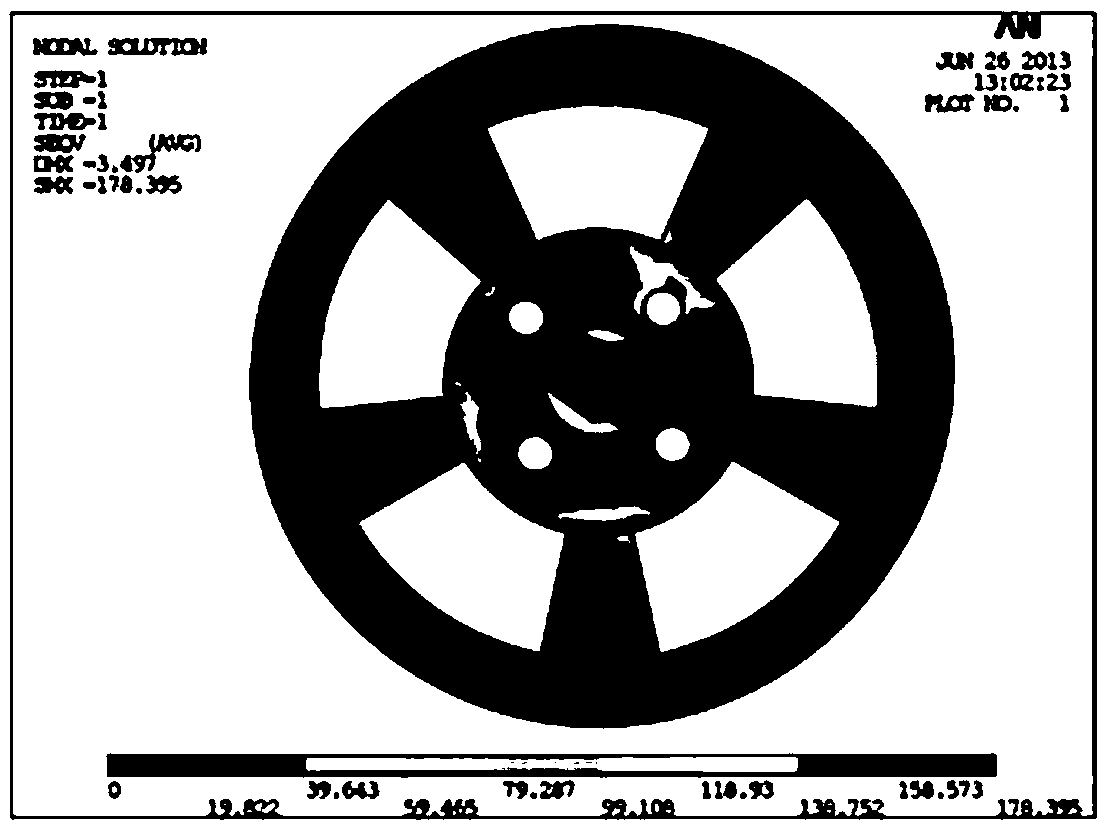

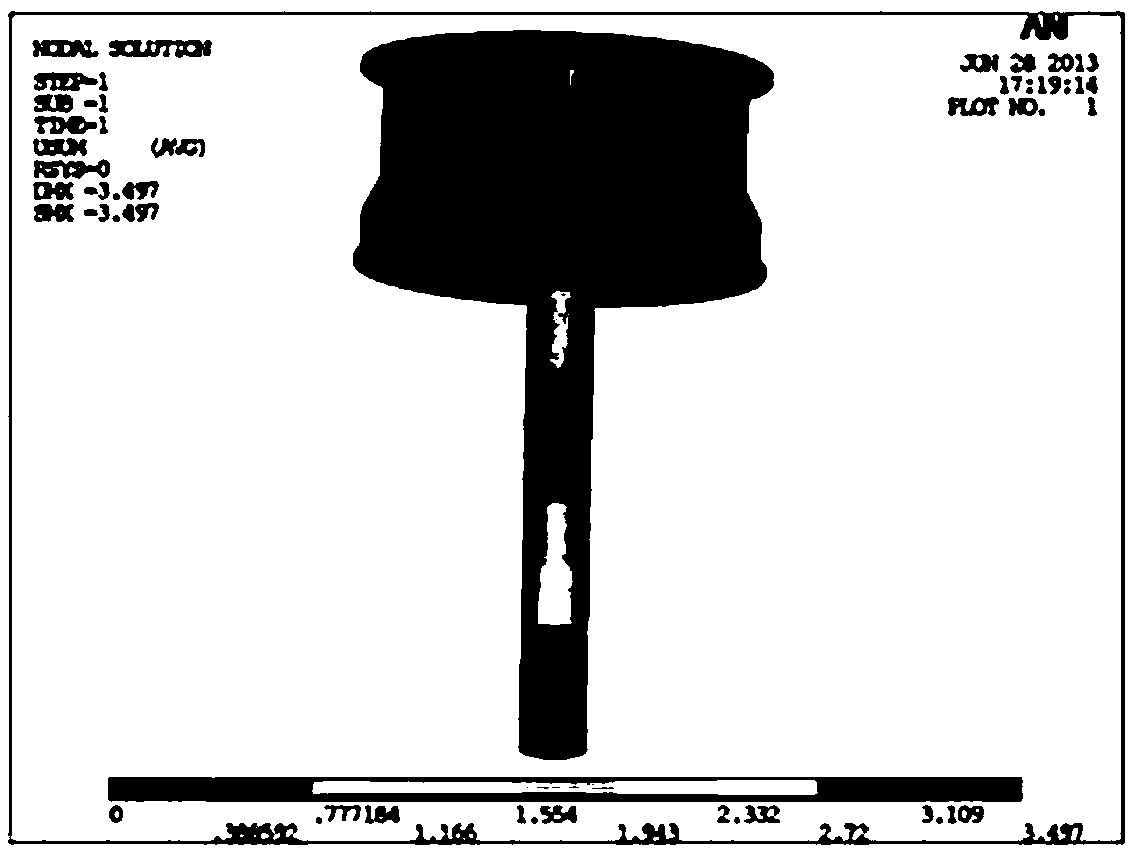

[0028] 1. Optimum design of high light weight and light weight automobile wheel hub.

[0029] After finite element analysis, on the stiffness constraints of the automobile hub, the stiffness of the hub can be measured by the overall deformation of the hub. Assume that the optimum value of the rim thickness TH6 is 5.0499 mm, the optimum value of the spoke thickness TH8 is 19.382 mm, the optimum value of the boss thickness TH1 is 32.812 mm, and the optimum values of the spoke and boss transition arc radii R11 and R7 are respectively They are 32.358 mm and 26.196 mm. According to engineering experience, the stress concentration of the wheel structure in the impact test is reduced, and the stress concentration of the spoke is usually dispersed. Reducing the thickness of the outer rim of the rim can increase the deformation of the outer rim during the impact process. By increasing the plastic deformation of the hub to absorb more energy, the mass of the hub is reduced from 5.88 k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com