Method and hole reaming device for one-time pile forming of pile body and pile cap

A one-time, pile cap technology, used in drilling equipment and methods, sheet pile walls, earthwork drilling, etc., can solve the problems of reduced local bearing capacity, low efficiency, and puncture of foundation mattresses, and improve the bearing capacity of foundations. The effect of strength, integrity and good quality, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

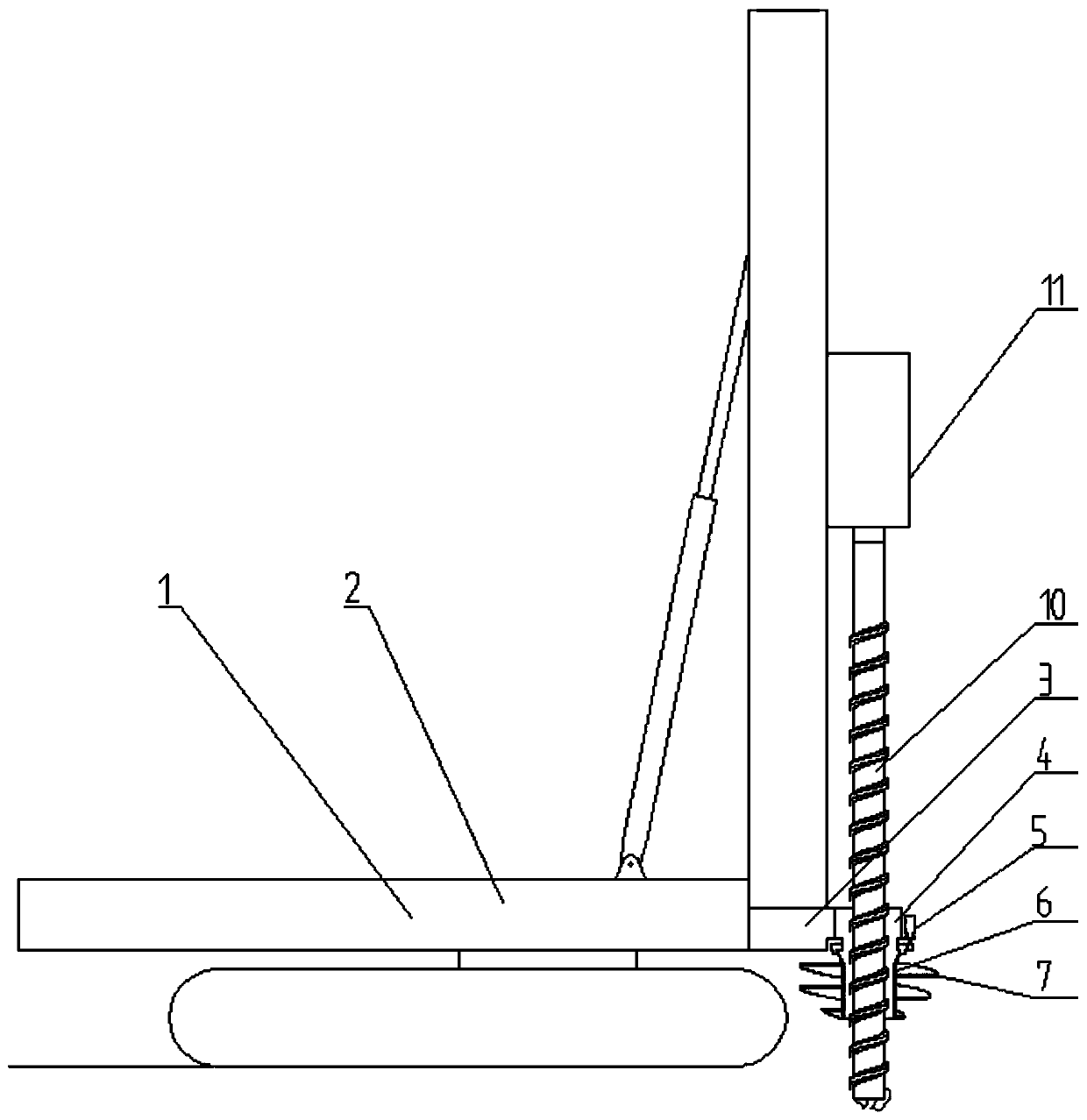

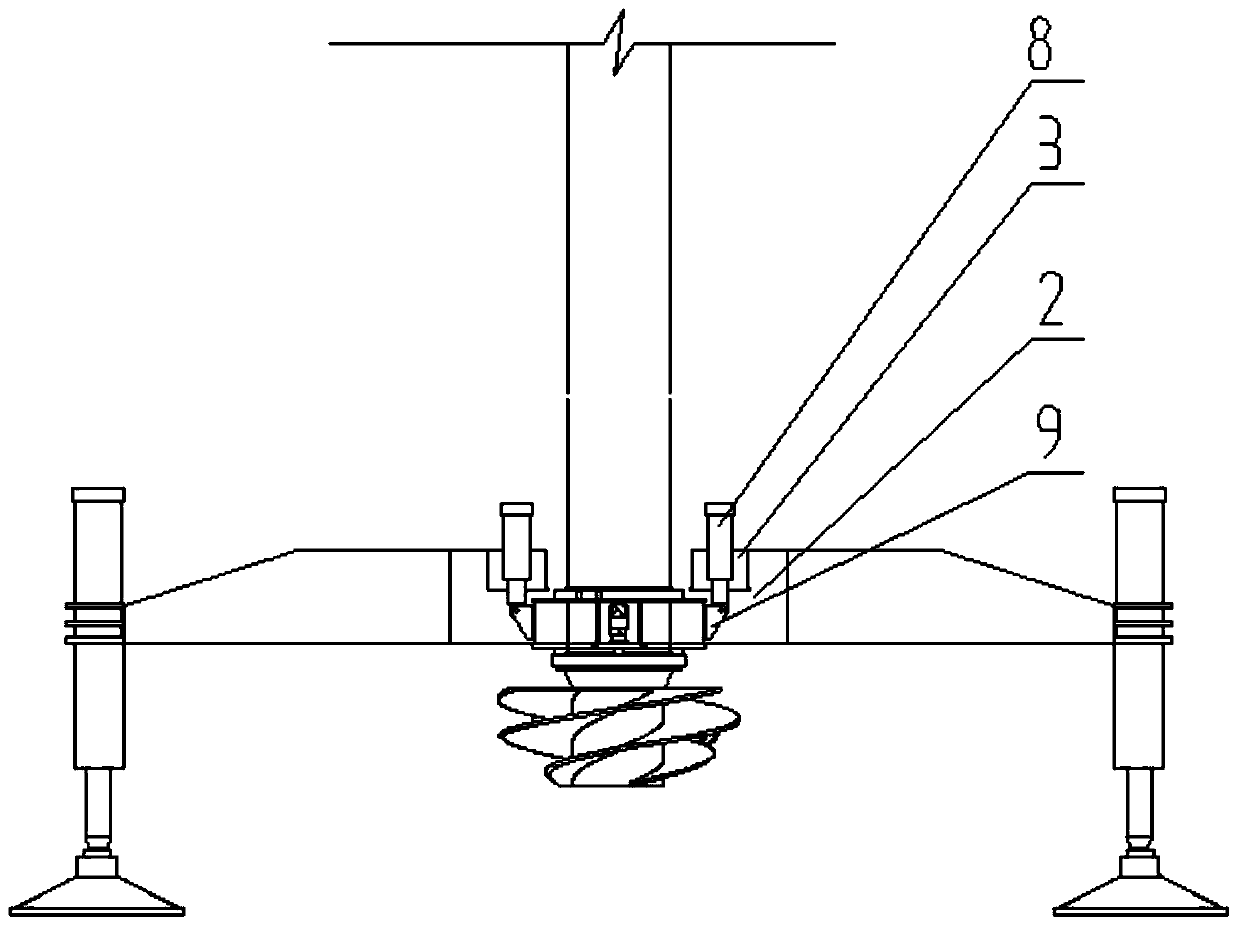

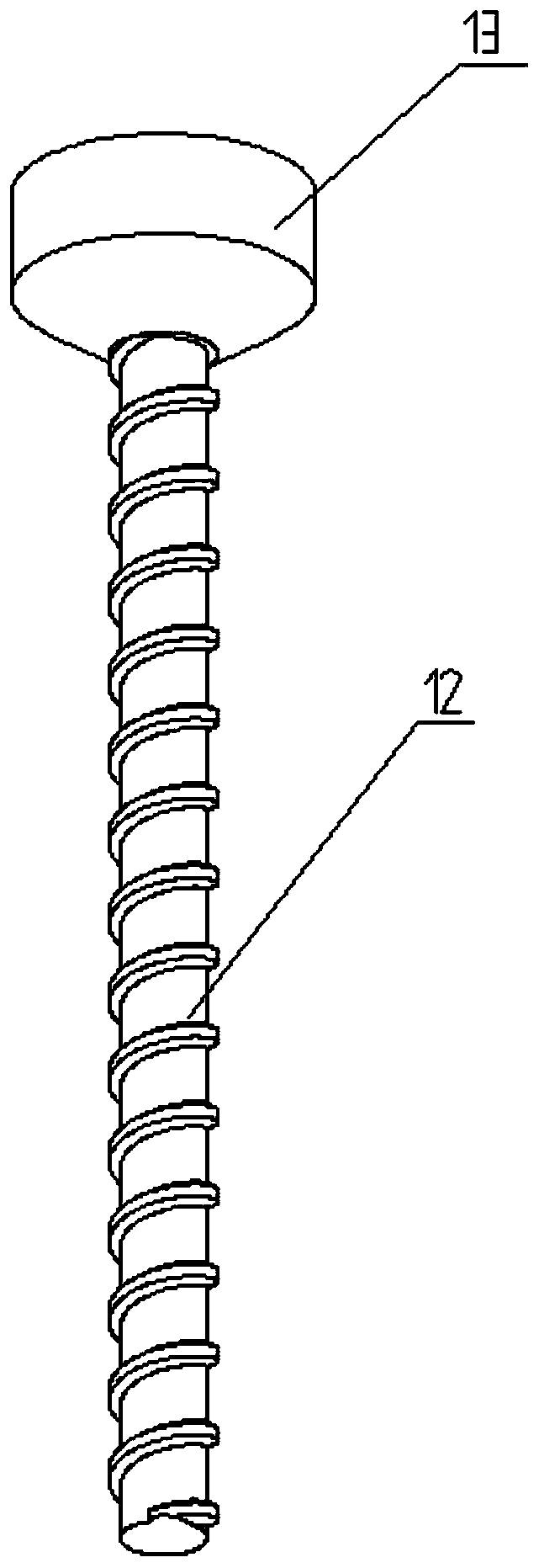

[0020] Such as figure 1 , figure 2 and Figure 4 As shown, a kind of pile body and pile cap of the present invention one-time pile reaming device comprises pile driver 1, pile driver girder 2, connecting seat 3, rotary box 4, hydraulic motor 5, slewing bearing 6, reaming Drill bit 7, pressurized oil cylinder 8, hinge plate 9, drilling rod 10, power head 11, reaming drill bit 7 are hollow, promptly its inside is cavity. The pile driver girder 2 is set on the pile driver 1, and the two connecting seats 3 are respectively connected with the pile driver girder 2 by flange bolts, the connecting seat 3 is provided with a pressurized oil cylinder 8, and the two connecting seats 3 can be respectively provided with a pressurized oil cylinder 8. There are hinged plates 9 welded on both sides of the rotary box 4, and the pressurized oil cylinder 8 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap