System and method for reducing emission of flashed gas in liquefied natural gas filling process

A technology of liquefied natural gas and flash gas, which is applied in the field of pressure transportation, can solve problems such as waste safety and hidden dangers, and achieve the effect of reducing waste and emission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

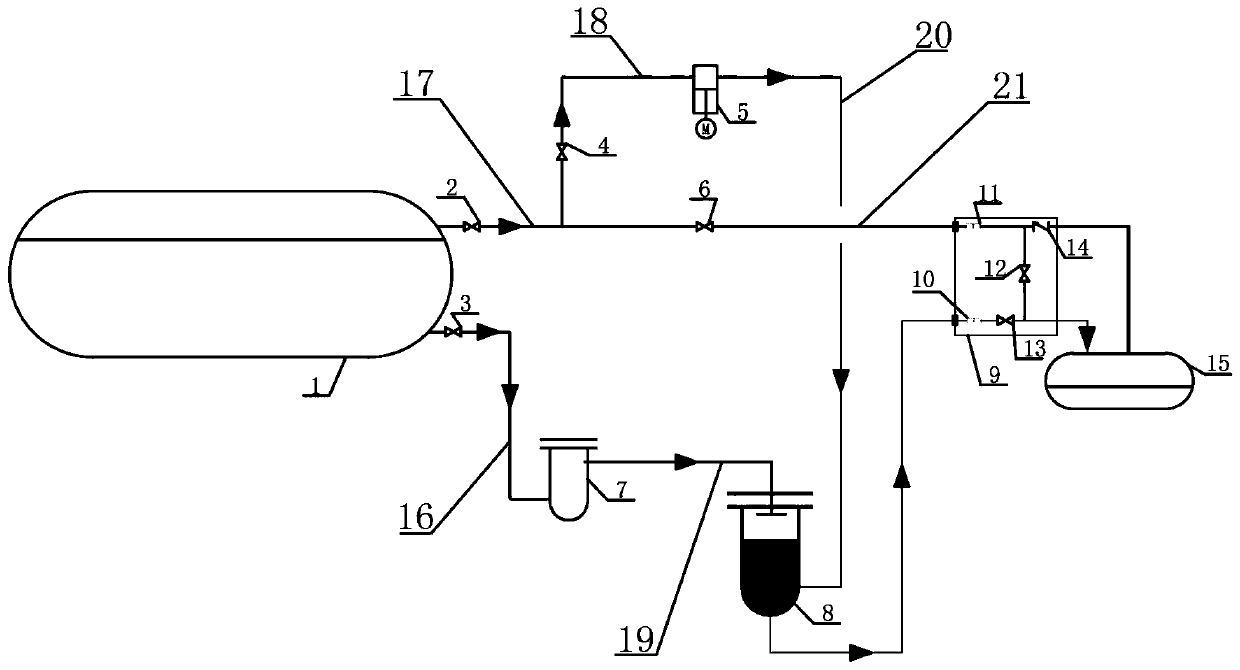

Embodiment 1

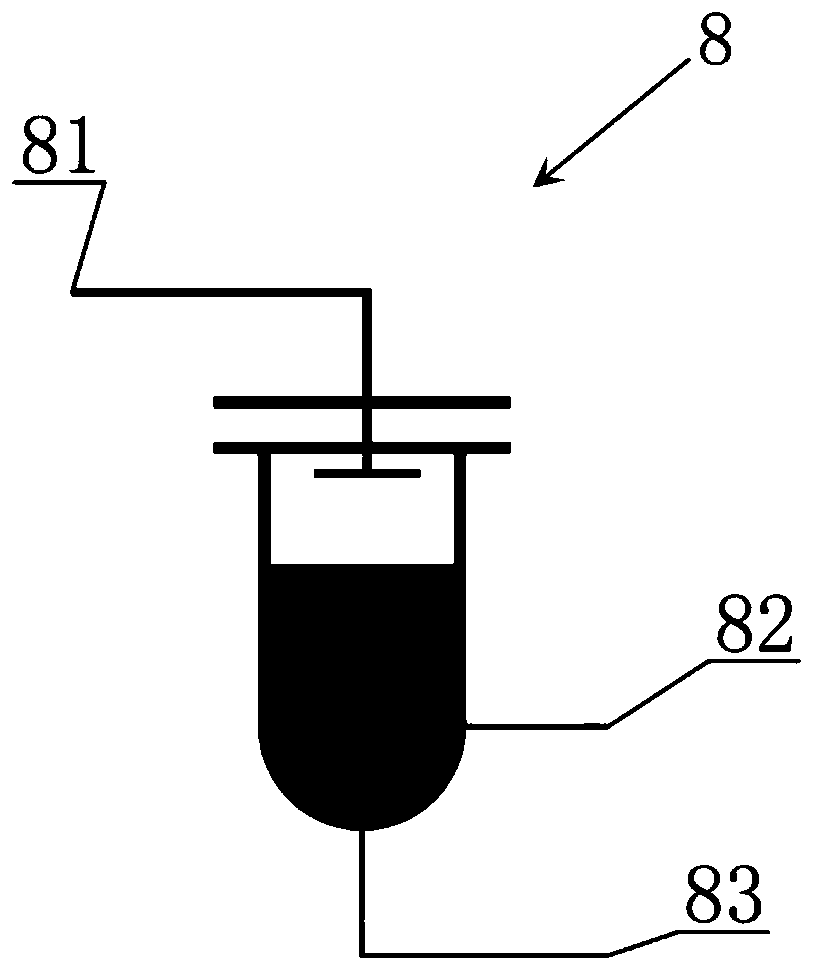

[0038] Such as Figure 1-2 Shown is a system for reducing flash gas emissions during liquefied natural gas filling. The system includes a storage tank 1, a submersible pump 7, a mixing tank 8, a compressor skid 5 and a fuel tank 15. The mixing tank 8 is A liquid phase inlet 81, a gas phase inlet 82 and a liquid phase outlet 83 are provided, the storage tank 1 communicates with the inlet of the submersible pump 7 through the first pipeline 16, and the storage tank 1 passes through the second pipeline 17 and the third pipeline 18 in turn Connected with the inlet of the compressor skid 5, the outlet of the submersible pump 7 communicates with the liquid phase inlet 81 of the mixing tank 8 through the fourth pipeline 19, and the outlet of the compressor skid 5 communicates with the liquid phase inlet 81 of the mixing tank 8 through the fifth pipeline 20. The gas phase inlet 82 of the mixing tank 8 is communicated, and the liquid phase outlet 83 of the mixing tank 8 is respectively...

Embodiment 2

[0049] A method for reducing flash gas discharge during filling of liquefied natural gas, said method uses the system described in embodiment 1; said method comprises the following steps:

[0050] a. Pre-cool the system before filling the fuel tank

[0051] The submersible pump 7 is pre-cooled first, and after the pre-cooling of the submersible pump 7 is completed, the submersible pump 7 is started, and the liquefied natural gas enters the submersible pump 7 from the storage tank 1 through the first pipeline 16, and then pressurized by the submersible pump 7 Afterwards, it is sent into the mixing tank 8 through the liquid phase inlet 81 of the mixing tank 8, and then enters the liquid feeder 9 through the liquid phase outlet 83 of the mixing tank 8, and the liquefied natural gas that enters the liquid feeder 9 passes through the liquid of the liquid feeder 9. The phase flow meter 10, the first valve 13, the second valve 12 and the gas phase flow meter 11 return to the storage ...

Embodiment 3

[0056] A method for reducing flash gas emission during filling of liquefied gas with a temperature of -273 to -20°C, wherein the liquefied gas with a temperature of -273 to -20°C is liquid nitrogen; the method comprises the following steps:

[0057] a. Pre-cool the system before filling the fuel tank

[0058] First pre-cool the submersible pump 7, after the pre-cooling of the submersible pump 7, start the submersible pump 7, liquid nitrogen enters the submersible pump 7 from the storage tank 1 through the first pipeline 16, and then pressurizes through the submersible pump 7 After that, it is sent into the mixing tank 8 through the liquid phase inlet 81 of the mixing tank 8, and then enters the liquid feeder 9 through the liquid phase outlet 83 of the mixing tank 8, and the liquid nitrogen entering the liquid feeder 9 passes through the liquid nitrogen of the liquid feeder 9. The phase flow meter 10, the first valve 13, the second valve 12 and the gas phase flow meter 11 retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com